Characteristics and selection of potato diggers for a mini-tractor

A potato digger for a mini-tractor is a useful device in gardening and dacha business. Growing potatoes is a popular but time consuming activity. A mechanized tool reduces both costs and energy for this labor. The modern potato digger is an attachment suitable for devices with a PTO shaft. Mini tractors and some walk-behind tractors just have the required characteristics.

Peculiarities

Any potato digger is designed to pull potatoes to the surface of the soil. The specificity of all devices is identical and is not associated with either the brand or the model. Despite the large number of variations, devices are divided into vibrational and simple ones.

Simple diggers are passive devices that work like a shovel or plow. Teeth or rods are simply welded to the parts. The plow goes deep into the soil, loosens and overturns. The potato rises on the rods, remaining on the surface.

The quality of work of such a digger is not considered effective: a lot of physical strength is still needed to harvest the harvest. The vibratory digger is also equipped with a shovel or share that loosens the soil. The vibrating part is a grating, which is also sometimes called a screen. Advanced models of vibrating potato diggers are equipped with conveyors or drums.

On the conveyor, potatoes are cleared of soil - clean vegetables are easier to collect. The drum mechanism is a rotating fan that throws the tubers to the sides. The drive of this fan is connected with lug wheels. Each farmer comes up with new and more convenient devices for his farm.

Mini tractor potato diggers

Simple and vibrating diggers are available in single row or double row. Both attachments are attached to a standard shed located at the rear of the tractor. The advantage of potato diggers in:

- a small amount of spoiled vegetables: thanks to the thrift, the tubers are not damaged;

- good cleaning speed, especially when compared with manual labor;

- simplicity of design, which is easy for a craftsman to make on his own.

The awnings are universal, suitable for various equipment. Modern improved models are equipped with a storage hopper. This device reduces the burden on the person involved in harvesting potatoes.

Any mechanized work entails some difficulties. The main disadvantage of potato diggers is their high cost. Therefore, many farmers are inclined to the idea of making equipment with their own hands. The development of such a technique is a laborious process. To work, you will have to study ready-made models on the market, or have good engineering skills.

Device and principle of operation

Drawings that are freely available on profile portals, of course, facilitate the task associated with creating a device, but a detailed knowledge of the principles of equipment will also be useful.

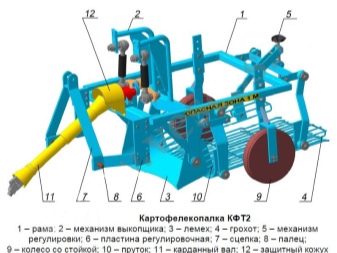

The potato digger device includes the following parts:

- an iron frame on which the constituent parts are attached;

- wheels;

- shafts;

- ploughshare;

- transport components;

- lattice.

The frame is the heart of the whole device.It takes the main load, so the steel used in its manufacture must be strong, and the welded joints must be of high quality.

The grate where vegetables are cleaned is also called an elevator. It is made from steel rods. A shaft is attached to the steel grate, the power of which determines the degree of vibration. The resulting structure is placed on the frame and secured with bolts. Next, knives are made that will cut the ground. They need strong curved steel. For homemade products, a piece of pipe is often used. The part is cut and unbend. Then its edge is sharpened.

A single shaft with bearings or separate hubs can serve as a wheel attachment. Wheels can be ordinary tires. There are also iron options equipped with lugs. The type of final attachment to the mini-tractor will be associated with the features of your existing model of equipment. A self-made trailing mechanism must match the factory tractor device.

Models and their characteristics

Domestic and Chinese mechanisms are presented in the attachment market in a wide variety. The most popular among the products of some manufacturers. Scout conveyor unit. The digger is suitable for mini-tractors and heavy walk-behind tractors with an engine power of 10-15 liters. with. The working depth of tillage is 28 cm. To use the digger with different modifications of tractors, different drive belts are required. For example, for models of Scout equipment, the B2360 product is useful, for Fighter mini-tractors, the B2550-B2600 belt is needed.

The same company offers a screening version of the digger, which is suitable for models of mini-tractors and motoblocks with a power take-off shaft. Apart from this coupling element, there are no other options for this model.

The Bomet Z655 single-row digger provides high-quality digging of vegetables in one pass. The principle of operation of the device is vibration. The width of the processed row can be changed.

It is noteworthy that the device not only removes soil from the tubers, but also cuts the stems. The grating is mechanically divided into two parts. Therefore, when harvesting, the branches are on one side, and the potatoes on the other. The digger is only suitable for mini tractors with engine power from 15 HP. with. The attachment itself weighs over 200 kg. This series potato sifting digger is known for its KK-10 and KKM-4 varieties.

The KK-1 conveyor attachments provide high-speed harvesting of potatoes. At a speed of 4 km / h, the device processes pieces of soil of the following dimensions: 25 cm deep and 65 cm wide. The device is suitable for powerful vehicles (18 HP).

KKM-3 - vibration version, standard for the MTZ tractor. The fan-shaped single-row digger is also suitable for other devices with a power take-off shaft. The equipment is inexpensive and has low performance.

How to choose?

The criteria for choosing a potato digger should be associated with the device of your mini-tractor. For example, if the capacity of the unit is not enough, it is better to pay attention to simple models. At the same time, one should not expect high work results from such a tool. However, spending money on the purchase of a device will turn out to be rational. Having at your disposal a powerful motor-tractor, you can think about purchasing a vibration-type digger with additional devices. Such a technique will simplify the work associated with harvesting root crops, but will require a large investment.

You should also compare the size of the site. Vibratory diggers are bulky. They are often not suitable for processing 5–6 acres of an ordinary vegetable garden. Controlling a mini-tractor with a connected vibratory digger is more difficult. The vibrations will give off and feel good.

In addition to the main selection criteria, you can take additional ones into account:

- soil properties;

- the amount of cultivated land;

- availability of finance.

Study in detail the information about the products presented in your region. Write down in the table the prices and characteristics that would be optimal for you. A detailed analysis will help you choose exactly the hitch that will be useful in your courtyard.

Operation and possible breakdowns

The operation of the digger when harvesting potatoes is impossible without knowledge of the technical safety rules. Familiarization with the technique will improve maintenance and understanding of the unit. The procedure for working with most models involves removing the tops from the field one to two days before the planned harvest. Harvesting potatoes begins with adjusting the blade travel and the hitching speed. During operation, it is important to clean and lubricate parts. The quality of the work performed must be constantly monitored. An unsatisfactory result may appear due to unit breakdowns.

Frequent malfunctions are caused by premature wear of parts. Many faults can be rectified by yourself. For example, if a knife is cutting tubers, you need to increase the tillage depth. This is done by shortening the talerp. The same method works in the case of twisting of the mass on the plowshares.

A lot of soil on the swath can be caused by too high a speed. The malfunction is eliminated by lowering the speed limit. Due to contamination of the working elements, the overload clutches are triggered. The cause of the seizure is eliminated by cleaning, and sometimes spring preloading helps. In vibration devices, the elevator often stops rotating. To eliminate the damage, you need to tighten the drive chain well. Sometimes it is sufficient to check its tension.

Checking and adjusting the chains is a mandatory maintenance item for the device. In addition to it, the required actions include:

- check of protective covers;

- checking the fasteners of parts;

- check of completeness.

All actions are required before the start of seasonal work. During the storage period, it is desirable every two months. Compliance with the recommendations will help to extend the service life of the equipment, as well as provide high quality potato harvesting.

In the next video, you can watch the Garden Scout mini tractor potato digger in action.

The comment was sent successfully.