Blade on a mini-tractor: do-it-yourself selection and manufacturing

Mini tractors are a versatile type of equipment, as they can function with various attachments. One of the most popular attachments is the blade. This equipment costs a lot, but quickly pays off due to a lot of advantages, and the owner can also make it on his own.

Features and purpose

A dump for a mini-tractor is a necessary equipment, the use of which is aimed at removing snow, cleaning the territory in the cold season. And also with the help of the blade, you can transport bulk materials without much effort. By attaching this equipment to the unit, work can be done within minutes. Dump-free procedures take several hours. A shovel for a mini-tractor can be not only purchased, but also made by hand, which contributes to saving finances, as well as convenient and comfortable work. It is simply impossible to do without a dump in the winter season, when it is impossible to leave the yard because of the snow cover. In order not to waste time cleaning the road manually, you can use this attachment for the unit.

Snow plows have the following components:

- shovel;

- grader fixation unit;

- a device that is designed to rotate an angle.

Thanks to the rigid design, the blade can cope not only with loose snow, but also with caked cover and ice. Models equipped with mechanical steering do not need to be fitted with a hydraulic line on the loader.

The equipment is protected from collision thanks to an additional pivot with a spring block. Thus, when hitting an obstacle, the blade deflects and jumps over it.

Advantages and disadvantages

The blade for a mini-tractor is the type of equipment that which is characterized by the following advantages:

- high-quality material of manufacture, which contributes to a long period of operation;

- speed and ease of operation;

- convenience at work;

- no need for your own efforts during the process.

The attachments have practically no drawbacks, except that they are not cheap, but this drawback quickly pays off.

Types and their design features

A dump on a mini-tractor is a type of additional attachment that looks like a bucket. Despite the same purpose - to remove the snow cover, the shovel comes in several varieties.

Front

This version of the hitch has a hydraulic cylinder in its design, due to which the unit is started. Such equipment serves as a bulldozer, as it has a front hitch. The mini-tractor is heavy, so when starting the shovel, some difficulties may arise during transportation. A mini-tractor with a front blade type is characterized by maneuverability, high-quality hydraulics. With the help of this unit, you can clear snow, level paths, level platforms. The front blade is fastened in a special place, which is provided for by the design of the tractor.

Rear-mounted

The grader type of equipment is defined as rear-mounted. The starting process takes place using the rear hitch.The unit is characterized by the presence of a swivel mechanism and hubs. Rear-mounted equipment can be connected to any brand of mini-tractors. Fastening takes place thanks to a three-point fastening system.

Unlike the previous version, this type of hitch does not have a hydraulic cylinder. Snow areas are cleared by reversing the machine. The equipment is made from high quality materials, therefore it has the ability to perform the most complex tasks. The rear dozer blade for a mini-tractor is used in the field of agriculture, as well as municipal. With the help of this technique, you can take care of the parking area, areas near schools and others.

The main characteristics of dumps for a mini-tractor of various models are the following:

- weight, which ranges from 65 to 105 kg;

- width - from 1, 2 to 2 meters;

- power unit, which can be no less than 16 horsepower.

How to use?

People who become the owners of a mini-tractor and a blade should know how to use it correctly. The front and rear plow is characterized by some features, as well as features of functioning. After purchasing the blade, it should be installed on the machine, while using specially designed fasteners. After that, you need to set the angle of work. If you need to clean the roads, then it is worth setting an acute angle. When removing snow cover over a large area, set a right angle. After all the above activities, you can start cleaning the snow.

Important! A purchased blade, just like a homemade blade, requires some knowledge and skills when used. For the correct functioning of the attachment, it is necessary to use it responsibly, otherwise injury to the user or damage to the device may occur.

It is worth paying attention to the following safety rules when using a mini-tractor with a blade:

- the use of attachments should be carried out in accordance with its intended purpose;

- during work, it is necessary to monitor the functioning of the blade;

- if the blade is filled with snow while driving, then it must be kept in a lowered state.

How to do it yourself?

For self-manufacture of a shovel blade, the first thing you need to start preparing the following set of tools:

- pliers;

- drill, grinder;

- welding machine;

- keys, screwdrivers;

- fasteners in the form of nuts, bolts, screws, rivets.

Among other things, it is worth preparing a steel barrel that has a volume of 200 liters, as well as strips made of rubber and steel. The scheme for making a shovel for a unit is as follows:

- the barrel must be cut into three parts - these will be the parts for the future equipment;

- two parts must be welded in accordance with the contour, as a result, the master will be able to get a product that has a thickness of 3 mm;

- to strengthen the lower part of the oval, it is worth installing the knife;

- the knife is made thanks to a strip of steel, which has a thickness of 5 mm, the length should be equal to the grip of the blade;

- it is worth drilling holes in the knife that will have a diameter of 5 millimeters, while the distance between the holes should be 10 cm; their main purpose is to place a rubber strip with a safety function;

- the width of the structure is affected by the power, as well as the size of the mini-tractor; the assembled dump should not be more than 0.4 meters on each side;

- to strengthen the structure, it is necessary to use specially designed longitudinal stops; steel pipes, which are characterized by a cross section of 40 by 40, will be an ideal option; these elements must be welded below the border on which the dump is located;

- The rubber shroud must be secured to the bottom of the blade to prevent friction between the device and the surface.

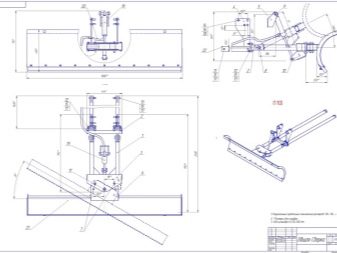

It is best to use pre-prepared drawings, which indicate the current dimensions, thanks to this you can make a homemade blade quickly and easily. Fastening a hinge plate made with your own hands must be carried out with particular reliability. Mechanical lifting assists in lifting the unit to the required height.

The features of attaching the dumps to the machines are as follows:

- welding of longitudinal type elements into A-shaped parts;

- fixing the bracket in close proximity to the central lintels;

- as a hydraulics option, it is worth taking a 2PTS-4 cylinder.

To connect each of the equipment parts into a single whole, you must perform the following activities:

- the attachment of the hinge occurs in the lower part through the front, while the bearings are connected in 2 bushings with a through type; do not forget to put the hydraulic cylinder;

- the upper blade element can be connected using a hydraulic unit;

- the control elements must be brought out through the cab and fixed with a remote control, a lever.

And also a method is possible that will help make a blade that does not have a lifting mechanism. This design is much simpler than the previous one, provided that the equipment frame is fixed in a fixed position, while the hinge on the structure can rotate to the right and left. To fix the hitch, it is worth taking such actions as:

- weld a disc of iron to the shovel, which has a diameter of 0.15 meters;

- drill 3 holes on the disc, which contribute to convenience and comfort;

- you need to insert an L-shaped pin into the grooves, it will help to hold the equipment;

- an elongated handle should be attached to the bucket;

- each of the mounting bolts must be tightened and fixed;

- paint finished equipment.

With the help of a ready-made home-made blade, you can not only remove snow. In summer, this unit can be used as an alternative to a bulldozer, which is capable of leveling the ground. The blade is a reliable and durable attachment that simplifies field work.

For information on how to attach the blade to a mini-tractor, see the next video.

The comment was sent successfully.