How to make a collapsible brazier: manufacturing technology

Barbecue cooking is a favorite culinary activity for many, both in summer and winter. After all, who will refuse a fragrant and juicy meat dish prepared from the freshest pork or lamb on a non-collapsible or stationary grill. As a rule, it is installed on a site cleared of snow near the house.

The brazier is useful for everyone, but it is best if it is portable. It is quite possible to independently carry out the manufacture of such a device, if you familiarize yourself with all the nuances of this process in advance. In addition to manufacturing details, it is also worth studying the features of the choice of material and taking into account all the rules for operating such a device.

Peculiarities

If you decide to make a homemade grill, then first you should make sure what size will be the best solution for you to meet the needs of your family. You also need to choose the metal that will be the most durable. Today, on the Internet, you can find instructions for making a large number of models of barbecues that can be made from various raw materials. However, it is logical that metal models are the most popular.

There are several reasons for this.

- The convenience of use. The metal brazier is easy to clean and wash, and if necessary, it can be easily disassembled if it has removable legs, or folded if it is foldable.

- Fast food preparation. It is the metal that holds the heat best, which makes it possible for meat and vegetables to cook on it not only as evenly as possible, but also quickly.

- High fire safety. If firewood or coal flares up strongly, then the dimensions of the barbecue and the fact that it is made of metal will be able to prevent the occurrence of a flammable situation. The metal may be very hot, but there will be no serious fire.

- Low cost. Now metal is one of the most affordable and inexpensive materials for the manufacture of any type of barbecue. It is much cheaper than natural stone, refractory bricks or other heat-resistant materials.

- Manufacturing speed. If there is welding and the required amount of metal, you can make such a brazier literally in two to three hours and immediately start using it. For comparison: a brick brazier will have to be made for about a month, and it will not be possible to use it for a few more days after completion.

- Mobility. Even if the grill does not unfold, it is still mobile - it can be easily transferred to any room such as a utility room or garage, where it will stand until it is needed again. In this case, it will not be negatively affected by various natural phenomena.

However, such a barbecue also has a drawback - not a very aesthetic appearance. But if you really understand what you are going to do, then turning the grill into a work of art will not be very difficult. Metal is also susceptible to corrosion, but thanks to the presence of special anti-corrosion agents and constant care for it, it will be able to serve you a considerable amount of time.

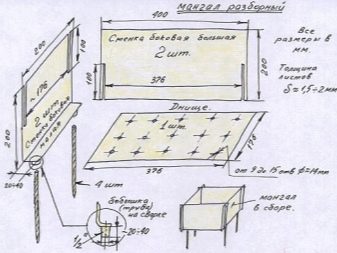

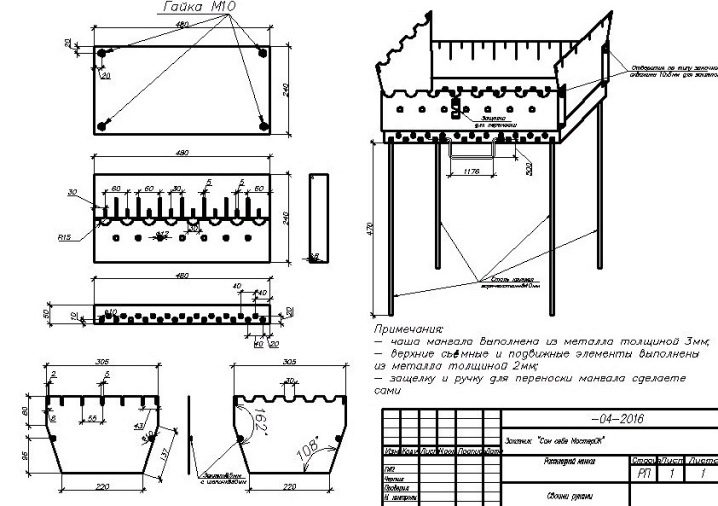

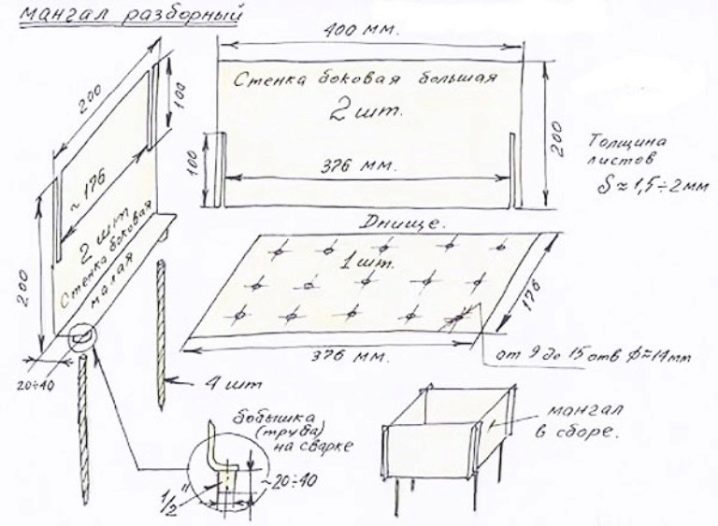

Drawings and dimensions

If you set out to make a brazier, then in order for the result not to disappoint you, you should clearly formulate your requirements and take into account all the important factors that may affect the usability of the product. For example, if your family consists of three or four people, then a barbecue with dimensions of about 50 by 30 centimeters will be enough for you. The last number indicates the width. This distance allows you to place a skewer over the fire, on which there will be somewhere 7-9 pieces of meat, depending on their size.

In addition, the length of the barbecue may vary. It all depends on how many skewers you want to put on the grill at a time. The standard distance between skewers is about 10 centimeters. That is, for eight skewers, you need a sheet 80 centimeters long, and for 9 - 90 centimeters.

However, you should immediately abandon the intention to make the barbecue too long. This solution will not only be inconvenient, but also make the structure itself extremely cumbersome.

If we are talking about the height of the barbecue, then it should be somewhere 15-20 centimeters. Such a volume will be more than enough to not only place firewood or coals in the grill, but also meat in such a way that it does not come into contact with burning coals at all during frying and does not burn.

If we take the whole structure, then the length from the bottom to the legs should be such that a person can stand straight and hold skewers in a bent hand, and so that it is convenient for him to turn the shish kebab during cooking. In addition, the grill should be such that it can be safely placed in the trunk. The car version should not take up much space. To make the legs, you can use the corners in the form of shelves of 25 or 30 millimeters, as well as four pieces of ordinary reinforcement with a diameter of 8-10 millimeters.

If you need a camping grill, then as an example, we will give the characteristics of one of the models.

Such a collapsible model will consist of the following elements:

- the base of the barbecue, made of a solid sheet of steel;

- legs that have a diameter of 2 centimeters;

- frame made of corners and 4 pipes for fixing with a diameter of 17 millimeters;

- two types of sides - longitudinal with three protrusions and side - with two;

- grate;

- various fastening elements - washers and nuts;

- bolts.

Such a grill is convenient because it is easy to fold. When folded, its length will not exceed 60 centimeters, and its width - 30 centimeters.

Tools and equipment

In order to make a folding brazier, you need to buy certain tools and items. These can be purchased at your local hardware store as they are quite affordable. You can also use materials at hand. You can make a simple structure without even using such a thing as a welding machine or fasteners. In this case, it will simply be necessary to create a system of grooves.

Speaking specifically about tools, then to create a barbecue you will need:

- a piece of sandpaper;

- pencil;

- ruler;

- roulette;

- drill with drills for metal;

- grinder and discs to it;

- scissors for metal.

If we talk about materials, then you only need a sheet of steel with a thickness of about 3-3.5 millimeters. Before you start cutting metal, you need to make a layout of your future barbecue from cardboard. This will make it possible to at least roughly see how it will look in reality and, if necessary, adjust parameters such as width, length and height depending on your preferences. In addition, cardboard blanks can be used as a template.

Manufacturing: the intricacies of the process

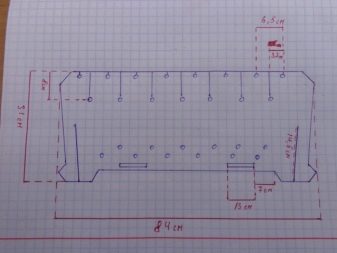

To make a prefabricated brazier with your own hands, you must first transfer the drawings from paper to metal and cut out the details. As an example, consider a barbecue grill with a volume of 60 by 30 by 15 centimeters.

In this case, the drawing will look like this:

- two side elements measuring 60 x 15 centimeters;

- the bottom of the barbecue measuring 60 by 30 centimeters;

- two end sides measuring 30 by 15 centimeters.

The legs can be either separate elements or a continuation of the end elements. If you give preference to the last option, then a number of adjustments must be made to the drawing of the end sides. It should be noted that for the convenience of using the barbecue, its height should be about one meter. However, it all depends on the height of the person, so a deviation from this parameter by about 20 centimeters is allowed.

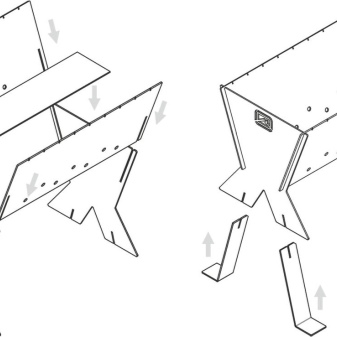

Before cutting out the details of the structure, you should decide which mounts such a folding brazier will have.

They are usually of two types:

- in the form of metal corners;

- vents, which are usually welded to the base.

If there is no welding at hand, this does not mean that you cannot use the second option. In this case, you just need to use a groove system, which will make it possible to make no less reliable fasteners. However, for this, in the drawings of the side parts, it is necessary to make two or three protrusions, which in their shape will resemble the letter "G". If we talk about the size of the protrusion-mountings, then it should be about one and a half to three centimeters.

In addition, in the details of the end on the drawings, places should be entered where it is necessary to make cuts of a vertical type in order to insert fasteners into them. They can also be made in order to firmly fix the bottom of the barbecue. And only after the issue with the fasteners is resolved, you can begin to cut parts from metal sheets. It is best to create details with a grinder.

When they are done, it is necessary to polish all sections with high quality. You should be extremely careful, as it is very easy to cut yourself on the sharp edges of the metal. Also, at the ends of your barbecue, you need to make holes that will serve as handles for it. With their help, if necessary, it will be possible to easily carry the grill to nature or rearrange it from place to place.

After completing the process of grinding the parts from the bottom of the side walls, you will need to make two rows of holes with a diameter of about one centimeter using a drill. Due to the presence of such holes, air can enter the coals. It is best to place them in a so-called checkerboard pattern, about 40-50 millimeters apart.

If, for some reason, you decide to make the legs of the barbecue removable, then nuts or corners for attaching the legs should be welded at all corners of the bottom of the barbecue. By the way, they can be made either from corners or from a metal pipe.

When everything is done, it will become necessary to assemble a folding brazier in order to evaluate its functionality. This will help to find flaws, if any, and quickly eliminate them.

Painting the finished barbecue

In order to protect the portable grill from corrosion and natural factors, it is usually painted. Previously, dyes were not used, and in general they tried not to use chemistry, since in the process of burning wood or coal, the paint began to peel off, emitted an unpleasant odor, the meat absorbed dangerous carcinogenic substances.

Today, manufacturers can offer paints that are safe to use. The only problem for them may be the high temperature inside the barbecue. Even the most resistant coating can simply not withstand high temperatures, burn out and crumble.

If we talk about heat-resistant paints that exist today, they include various options.

- Heat-resistant powder paints that are perfect for coating homemade barbecues. But the technology of their application is not easy, since firing at very high temperatures is required.

- Enamels based on porcelain stoneware. Such paints can withstand temperatures up to + 600 degrees Celsius.

In addition, it is possible to carry out oxidation of the metal, which is also known as bluing. This process is quite complicated, but with a strong desire, it can be carried out even in an artisanal way at home. For this, the barbecue box must be treated with 5% sulfuric acid. After that, the structure must be boiled in a thick solution of alkaline soap for an hour and a half.

An alternative is to leave the grill in sodium solution for two hours. After such procedures, the metal will simply be covered with a black non-stick coating, which will be an excellent protection against corrosion. However, this method is rather unsafe, as the sulfuric acid must be handled with care.

Usage: tips

After each use, a collapsible brazier must be cooled and thoroughly cleaned from soot and ash, which will surely settle on its walls and bottom. It should be said that in no case do you need to extinguish the grill or cool it with water. The metal must cool in an exclusively natural way.

Another important tip is that after the end of the barbecue season, the grill must be disassembled and inspected for deformations. If defects are found, then they must be eliminated, and paint chips should be tinted. In addition, you need to lubricate various movable elements or sheds for the winter, if you used them.

As you can see, making a brazier with your own hands is not so difficult. The main thing is to accurately calculate all the parameters, as well as to have minimal skills in working with metals. Thanks to this, you can easily and fairly quickly make the brazier of your dreams with your own hands and enjoy amazing kebabs at any time of the year.

The design of the quick-assembly barbecue (without welding and other fasteners) is clearly demonstrated in the video.

The comment was sent successfully.