Manufacturing barbecues from metal: choice of material and project

Braziers and barbecues are an indispensable attribute of outdoor recreation. The most popular options for the execution of braziers are metal products. They have many advantages that allow you to cook a wide variety of dishes with exquisite taste and aroma.

Peculiarities

Metal is the most common material for the production of barbecues and barbecues. Such structures are lightweight, easy to carry and disassemble. The metal heats up quickly and retains heat well, which contributes to an even and quick frying of fish, poultry and meat.

As a rule, products are made of two types of steel: stainless and heat-resistant.

Metal selection is a very serious task., since in the process of use, under the influence of high temperatures, the brazier is deformed - the boxes begin to resemble helicopter blades, which are twisted in the direction of the main axis. Experts call this phenomenon plastic deformation. All structural elements are interconnected, therefore, internal stress arises, which causes a significant change in the shape of the barbecue. In the future, this leads to a complete loss of shape and destruction of the product.

That is why braziers made of stainless steel are not of high quality. This material is very afraid of burning out, so the grill serves no more than 1-2 seasons. Heat-resistant steel allows you to create models that are more robust and durable. The alloy contains a high percentage of chromium; this metal oxidizes at elevated temperatures and forms a refractory coating. In addition, the very production of this material is based on the addition of active components that prevent deformation and fracture of steel in adverse conditions.

Experts recommend using steel grades 10G2, 09G2S and 16GS for the production of barbecues and barbecues. They can withstand several thousand combustion / cooling cycles. But alloys ST10, ST20 or ST3 are more often used for tourist models, which are characterized by low weight and short service life.

In addition to temperature resistance, heat-resistant steel is characterized by corrosion resistance and wear resistance. It is not susceptible to shocks and mechanical damage of weak and medium strength, therefore it is optimal for the production of braziers that are operated outdoors in high humidity conditions.

The advantages of metal braziers include:

- good heat retention;

- low flammability;

- ease of operation and cleaning;

- mobility;

- light weight;

- low price.

Braziers and barbecues can be bought in specialized stores, and they are also widely represented in construction hypermarkets. There they are realized in standard shapes and sizes. However, if you want something unusual, you can order a brazier according to an individual project in the blacksmith's workshop. Such models, as a rule, are decorated with forged elements and decorated.

However, such installations are not easy, therefore they are used as stationary models. And the cost of such work is quite high.

Views

Before buying or making a brazier yourself, you should be very thoughtful about choosing the optimal model.

The decision depends on many factors:

- availability of space in the country;

- the need for transportation;

- brazier dimensions;

- the possibility of cooking different dishes.

If we talk about barbecues, then it is customary to divide them into three categories.

- Mobile option can move freely from one place to another. Its exceptional features are considered to be light weight, the ability to assemble, disassemble and install, small dimensions. At the same time, to ensure the required lightness in the manufacture of tourist structures, thin-walled steel is used, which quickly burns out and collapses.

- Mobile grill - this is a kind of street cart on wheels, such a brazier is also convenient to move. However, it is impossible to disassemble it, fold it and place it in the trunk of a car. Such barbecues are often decorated with wrought iron elements. They include a compartment for storing fuel and are equipped with a table top.

- Stationary option Is not only a grill. It is rather a small architectural form. It is installed in one place on the foundation, therefore, it cannot be moved.

- BBQ ovens are characterized by great variety. They differ in both their appearance and user characteristics, their prices also vary in a fairly wide range.

- For hiking, it is convenient to use a disposable model, which is a sheet metal pallet mounted on a fire-resistant support. A lattice is placed on top, where the product blanks are stacked. After the first use, the pallet is thrown away, because, under the influence of heat, it is deformed and cracked.

- Portable mechanism also useful for travelers. However, it lasts longer than the first option. This design looks like a grill with a brazier, which can be installed in several planes. It is quite convenient for small and large companies.

- Cauldron Barbecue has a domed cover that provides a number of additional functions. Such structures are protected from snow and rain, which means that an appetizing dish can be prepared in any weather. Also, thanks to the lid, the barbecue works in oven mode, and this allows you to fry meat in large pieces or whole poultry.

- BBQ cart - model with built-in wheels. It is quite easy to move it from one area of the adjoining area to another. It has a shelf for storing firewood and coal and looks very aesthetically pleasing.

Other samples are also on sale. Products with an exhaust hood and a chimney are widespread, so any buyer can choose exactly the modification that fully meets his individual needs and capabilities.

Forms

A brazier brazier can have the most varied appearance.

The following modifications are most common:

- Topless boxes are the most common and standard option.

- Rounded bottom gutters. Despite the incomprehensible name, in fact, such a grill is a simple barrel or gas cylinder, in which the top was cut off and converted into a brazier. This is a favorite model of home craftsmen, which decorates the summer cottages of many Russians.

- A cylinder with a throat on top looks like a bottle. It is used for cooking karski kebab - it is a large piece of meat, comparable in size to the dimensions of a small plate. With this type of construction, the skewer is installed on the "neck", which turns into a flow oven during cooking.

Stationary barbecues, in turn, are subdivided into:

- open;

- semi-closed;

- covered;

- decorative.

Dimensions (edit)

In order for the brazier to fully meet your needs, it is very important to know the technical features of the brazier of different types, the dimensions and dimensions of its individual elements.

Wall thickness

This parameter directly affects the service life of the barbecue: thin-walled products will last no more than 2 seasons, and models made of thickened metal will retain their operational characteristics much longer. The recommended wall density is 3 mm or more. It is this size that protects the material from premature burnout and deformation.

Lenght and width

The width of the structure depends on the length of the skewer. It should fit and stick to the walls of the barbecue. Therefore, with a standard size of rods of 40 cm, the width of the barbecue should be determined at 30 cm.

As for the length, it is directly proportional to the number of skewers placed on the grill at the same time. The only thing to consider is the recommended distance between them. It has been experimentally established that skewers should be placed at a distance of 8-10 cm from each other. If they are stacked more tightly, then the meat may not be fried.

Let's give an example. For a company of 3-5 people, there is enough meat on 8 skewers. If you place them at the recommended distance, then the total length will be in the range from 65 to 80 cm.

Depth

This is a very important criterion on which the taste and aroma of barbecue largely depends. It is believed that the most fried and juicy meat is obtained, located 15-20 cm from the coals. If the meat is closer to the coals, then it will become dry and may burn, and if you place it at a greater distance, it simply will not be fried and will be moist inside.

Ventilation holes

Users still cannot agree on the appropriateness of the holes. Some consumers claim that through them the necessary blowing is provided, thanks to which the meat is better fried. Others argue that this is a device for a "lazy cook", and the flow of air can be freely provided with a fan.

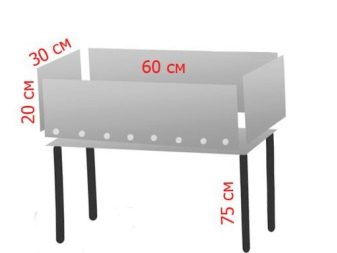

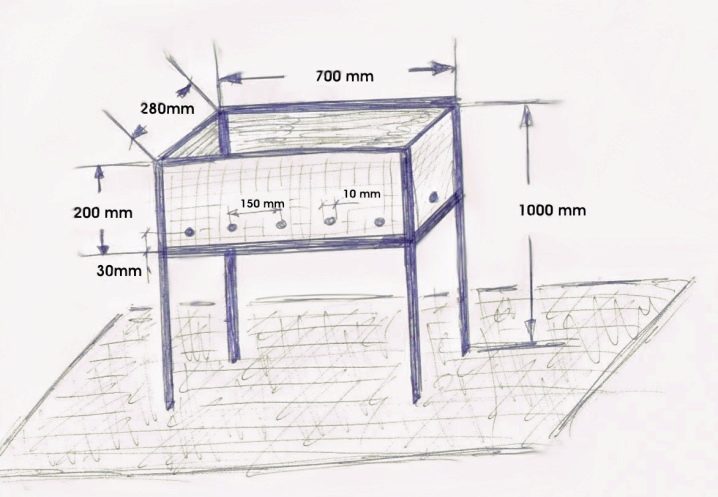

The dimensions of the "ideal" barbecue are approximately as follows:

- Width - 25 cm. This is enough to accommodate 6-7 small pieces of meat. With such a distance, all the pieces, even those in the middle, receive heat from the side walls evenly, so the meat turns out to be fried with a fragrant crust. If you increase the width, then the pieces in the middle will be without a crust.

- Length - 100 cm. For a medium-sized company, as a rule, meat is cooked on 7-8 skewers at the same time. Considering that the distance between them should be 8-10 cm and 5 cm on both sides of the edge, it is this optimal value that is calculated. It is not recommended to make the grill longer. In this case, the cook will have to constantly move from one end to the other in order to work with a fan and turn over the skewers.

- Tank height - 20 cm - calculated based on the optimal distance between meat and coals, which is 15 cm, as well as the place for placing coals.

- It is advisable to use metal with a wall thickness of 2 mm or more. If the grill is planned to be used on hikes, then it is worth giving preference to sheet steel with a strength of 4-6 mm.

- The total height of the barbecue depends on the size and height of the culinary specialist, but on average, a parameter of 1 meter is considered normal.

Advantages and disadvantages

The advantages and disadvantages of metal braziers directly depend on the material from which they are made and its thickness. Let's take a closer look at the most popular varieties.

Iron brazier

The selection of iron barbecues is great. They differ in their functionality, so it is very important to determine from the very beginning what you need a brazier for. If you plan to use the product on hikes and during picnics in nature, then you should purchase collapsible models made of thin-walled metal. They are lightweight, easy to assemble and disassemble, and are considered easy to transport and store.

However, there is also a drawback - thin steel burns out quickly, so such barbecues are not recommended for lighting coals.

It is advisable to make a fire in another place, and as the fuel burns out, transfer the coals to the brazier. In addition, such models have a limited length, which does not allow you to simultaneously cook barbecue for a large company.

Braziers with thick walls are more expensive than thin-walled ones. They are heavier and difficult to move. The advantages are also obvious: such barbecues are resistant to high temperatures, they do not burn out, heat up well and keep warm for a long time, ensuring uniform and quick cooking of meat.

Cast iron barbecues are also very popular among summer residents and owners of private houses.

This material has a number of advantages:

- fast heating and long-term retention of heat;

- aesthetic design (models are often decorated with forged elements);

- durability (cast iron barbecues can last up to 100 years and be passed on from generation to generation);

- the absence of foreign aromas in the prepared dish;

- the ability to work as an oven and ensure the highest quality roasting;

- resistance to temperature extremes, moisture and other unfavorable environmental factors;

- lack of tendency to corrosion.

The disadvantages are also significant:

Such models, as a rule, are made to order and have a rather high cost. They are also distinguished by their large dimensions and impressive weight.

Stainless steel

Stainless steel models are economy options that are quite low cost. However, the price is perhaps the only advantage of such products.

The disadvantages are so significant that they make all the savings impractical:

- Stainless steel quickly burns out, deforms and cracks under the influence of heat.

- It retains heat poorly - this leads to an increase in fuel consumption, and much more time is spent on cooking kebabs.

- Short term of use - stainless steel products last no more than 2 seasons, and with frequent use, they are enough for only one summer.

Material preparation

The main for the production of barbecue are metal sheets. It is not worth using other materials in addition, since it is the metal that provides the necessary heat and the degree of heating of the structure.

To work on creating a standard barbecue, you must use:

- metal sheets 25x25 cm - 2 pcs;

- metal sheets 24x25 cm - 2 pcs;

- metal sheet 54x25 cm - 2 pcs;

- pipes or corners - 70cm.

You will also need a tool for working with metal:

- drill;

- Bulgarian;

- welding machine;

- roulette.

Sheets of metal are used to create the bottom and side walls of the barbecue, but some craftsmen prefer a different installation method. They replace several sheets with one large sheet, then make several cuts, bend the sheets and join them with a minimum of welds. In this case, the installation will be more dense and durable. However, such jobs require knowledge and skills in working with metal.

At the stage of preparation of work, preliminary marking is carried out.

All the places where fasteners will be installed and welding will be fixed, and the area of holes for skewers is marked.

If the conceived design differs from the traditional one, then you need to stock up on additional elements that you may need. These include: pallet, handles, leg recesses and other parts.

Many people make a brazier using fittings as legs. But such a design is not entirely reliable, since too thin legs do not hold well the weight of the barbecue with skewers, so the installation staggers at the most minimal loads. It would be more correct to give preference to corners. They will provide the necessary strength of the supporting elements.

Stages of work

The main work on the manufacture of the barbecue is carried out in accordance with the scheme:

- The grinder cuts out all the main parts from metal sheets.

- Holes for air ducts are made on the side walls - they are drilled 2 cm from the bottom with a step of 5 cm, the diameter is 1-1.5 cm.

- Holes for skewers are cut out along the upper edge of the sidewalls, the outer ones are made at a distance of 5 cm from the edge, the rest are made in 10 cm increments.

- The bottom and sidewalls are welded together. You don't have to make a perfect seam. It is enough to fix the mount pointwise. This gives the necessary strength and at the same time creates conditions for a greater air flow.

- Legs are welded at the corners of the structure.

A hand-made shashlik maker can be considered ready on this, and the grill can be used. However, if you wish, you can weld decorative elements: handles, lid and other details. Before use, it is advisable to paint the grill with heat-resistant paint, which will protect the structure from heat and corrosion.

Original ideas

Beautiful braziers are made with forging elements.

Interesting options are made in the form of animals.

Exclusive barbecues in the form of trains, cars and planes will adorn any site.

And a few more photos of stylish barbecues.

For information on how to make a brazier out of metal with your own hands, see the next video.

The comment was sent successfully.