Types of fence posts from profiled sheet and from installation

The types of fence posts from the profiled sheet and their installation are the topic of numerous discussions on construction portals and forums. Decking is a popular material for the manufacture of hedges, but it is the pillars that give the structure the necessary strength and stability. The correct choice and correct installation is a circumstance thanks to which the fence posts can become an additional decorative element, giving the fence a special attractiveness and originality.

Species overview

The prevalence of a fence made of a profiled sheet is quite understandable if we recall the extensive range of industrially produced materials, colors and performance. Fence posts made of profiled sheet are a variable category. Their material of manufacture and dimensions are determined by the parameters of the profiled sheet.

Of no small importance is the decorative appearance of the building material, the relative ease of installation, the strength and durability of the structure, built in compliance with certain rules. They are necessary because of the special property of the material.

Lightness as a virtue which is especially appreciated by developers, in strong winds it can contribute to the development of the sail effect. The installation of metal pillars requires knowledge of certain subtleties. Insufficiently well fixed on the frame of the structure, the sheet is able to demolish the entire structure and break away from the strongest fasteners.

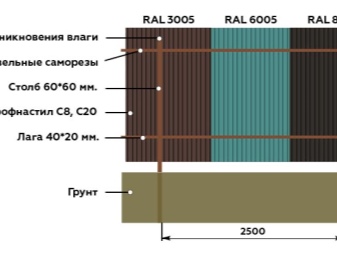

The second drawback of a fence from a profiled sheet is the burning out of the coloring pigment under the influence of scorching ultraviolet radiation. There are two ways to solve this problem - choose a shade that is least exposed to merciless sunlight or periodically paint.

But you can only cope with the weather conditions by choosing the right pillars, calculating their required number and securing them securely to the frame. Each owner has their own priorities. The choice of material for the pillar can be based on personal preferences, dictated by the available means at hand, financial or aesthetic considerations, and the utmost ease of installation.

Of the common options, the following types can be distinguished.

- Metallic. This definition includes racks made of a round or shaped pipe, purchased or cut independently, as well as variations of rolled metal products.

- Brick posts, massive, on a solid foundation, erected with special masonry on cement or created as a decorative design around a volumetric metal pipe.

- Fence posts made of profiled sheet can be wooden - This is a cheap structure, designed for a short time due to the ability of natural wood to become unusable under the influence of weather conditions, decay or pests.

- Screw piles - a progressive method, which is now in a special trend due to the strength and reliability of the supports installed by this method, in all their diversity. Although, since they are made of metal, they can be roughly classified in the first category.

- Reinforced concrete supports, with a heel for deepening and an external groove, with ready-made recesses, or made independently from reinforcement and concrete using wooden frames.

- Asbestos concrete, quite decent appearance, not subject to decay and corrosion, and even cheaper than metal.

It is impossible to persistently advise which is better. On closer inspection, it turns out that each type has its positive and negative sides. Therefore, the choice remains with the developer, who solves the problem of pillars for a fence made of corrugated board, based on considerations of aesthetic visualization, budgetary cost or some other practical reasons.

Metallic

The stability and strength inherent in metal posts led to their widespread use. There are several compelling arguments in favor of a metal frame.

- Variety of commercially available products, manufactured with high quality, industrially. These are pipes of variable cross-section (round, rectangular and flat), channels and I-beams, ready-made racks with fixtures for reliable fastening.

- The possibility of self-cutting with the presence of tools and minimal skills in working with metal. The strength and stability of the fence with correct calculations and a sufficient number of posts.

- The ability to use ready-made racks. Blanks for certain parameters of the profile sheet and plugs made of polymeric materials that close the pipes from the end to prevent corrosion inherent in metal from natural precipitation.

The hedge builder can have understandable difficulties in choosing the right metal product. He will have to pay attention to the quality of the material (it mainly determines the cost), the length and type of section, diameter, wall thickness, the required number of pillars.

The best option is called galvanized steel supports. This is the only clue to supporters of the point of view that the pillars must certainly be of the same material as the main fence. Otherwise, when determining the required parameters, you will have to focus on the sheet purchased for the fence.

Wooden

Wooden supports have long lost their former positions in the rating of demand. As pillars for a profiled sheet, wood products are short-lived, require constant care and special treatment, often repeated. The cross-section of a lumber post should be at least 10 cm, then there is a chance that they will adequately cope with the windage of a metal sheet. Experts advise to be careful about choosing the least rotting wood variety. Buying larch or oak logs will solve the problem of rapid decay of the underground part, but will lead to a significant increase in the cost of the structure.

In modern conditions, wood is used only if it is available in abundance. But when making such a choice, do not forget about the potential for replacement after a short period of time.

Brick

Brick poles are popular and can be found on every street in the private sector. Claims that this option is chosen because of the cheapness of building materials and ease of installation are not confirmed in practice. Brick supports also require a strip foundation, often instead of a banal brick, its more expensive imitation of decorative tiles is used, and the pillar itself is made of concrete. It remains to think that the material for the pillar is chosen because of the solidity of the look and beautiful, aesthetic visualization.

The problem of the strength and durability of the structure is solved in different ways, but if a foundation is used, the profiled sheet is fixed quite reliably, with special devices, and such a fence can serve more than one generation. Therefore, certain difficulties during installation are more than compensated for by many years of trouble-free operation.

The use of decorative tiles with an imitation pattern on a concrete support somewhat increases the cost of building materials, but makes the fence more durable and simplifies the installation process. Perhaps this is the real reason why such a fence is gaining more and more popularity.

From asbestos cement

The cheapness of the fixture does not mean ease of installation.The reliability of the support is guaranteed by the cement filling, which is done after digging in the lower part. Often, to give special strength to the structure, pipes made of this material are installed on a strip foundation.

You can also install a brick pillar on it, then the decorative component will increase many times over.

All aesthetic considerations outweigh the undeniable advantages of asbestos-cement pipes: durability, low cost and lack of maintenance. Products are not subject to decay or corrosion, do not require painting, impregnation with special compounds. This does not mean that this type of pillars does not have any drawbacks at all: in addition to difficulties during installation, they are unattractive and fragile enough, they are destroyed by mechanical stress.

Dimensions and quantity

The calculation of the required number of pillars for installation depends not only on the selected type of pillars, but also on the profiled sheet that the developer intends to use in the construction of the fence.

- According to the current rules, the construction of the fence is the primary responsibility of the owner of the land plot. Therefore, the development of the site always begins with a drawing on which they plan the location of buildings at the required SNiP distance from the fence.

- The best option is to purchase ready-made metal racks adapted to the parameters of the workpieces (the required pipe wall thickness and its diameter are taken into account).

- Complete with blanks cut from the profiled sheet, there are not only metal posts, but also polymer plugs for them.

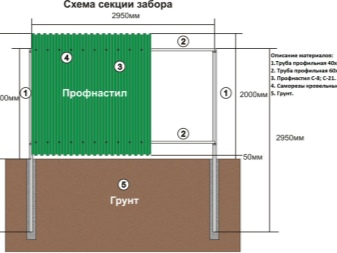

Before making a purchase, you need to make measurements of the fence line, taking into account possible difficulties, if the configuration of the site is not a square or rectangle. Then you can calculate how much is required. If the cutting is done independently and the height of the fence is 2 m, it is recommended to install the post from the post at a distance equal to this parameter.

Installation

The choice of the optimal type of racks made of a square shaped pipe does not mean that they can simply be buried to a depth in any order. Such placement will certainly lead to the destruction of the building in the near future, especially if the wind is constantly blowing in the area.

The algorithm of actions is as follows.

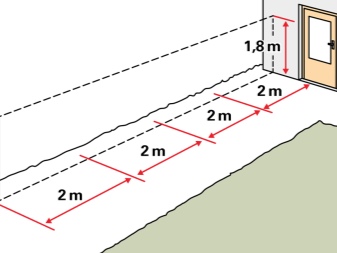

- The site is being cleared along the entire perimeter (one meter from the border on each side);

- At the site of the future pillar, a peg-mark is driven in, with an allowance of several centimeters on the transverse posts;

- It is recommended to place the pillars at a distance of 2 to 2.5 meters, so you need to immediately purchase the required amount by making calculations, deciding what step will be between them and dividing the length of the perimeter by this figure.

- It depends on the estimated height of the fence how much the support needs to be buried (at 2 m - 1 m into the ground or below the freezing line), if we are talking about unreliable soils.

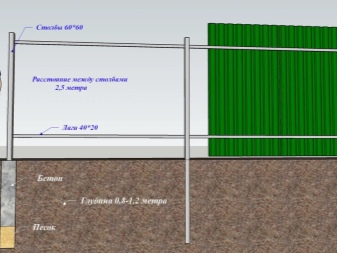

- Do-it-yourself installation begins with making grooves. Since you will have to dig in to a depth of more than a meter, the use of a drill is recommended (it will give a narrow deepening, which should not be wider than 15 cm).

- After immersion in the hole, the perpendicular and the required aboveground part are checked for compliance with the already defined parameter.

- Only after the height has been corrected (by adding or removing some of the sand from the bottom), can the prepared concrete be poured.

- In order for the structure to be strong, it is necessary to concreate a wider plastic pipe, put on top of the metal one, and fill the gap left between it and the walls of the hole with sand.

The reliability of the erected fence depends on how all the recommendations are fulfilled. Correctly installing the future frame for a solid fence means not just following the layout of the pillars, installation in places where the marking pegs are hammered.The quality grade of concrete and the recommended technology for preparing the poured solution must certainly be taken into account (experts advise adding building crushed stone or fragments of building materials for strength).

It is necessary to prepare concrete in small portions and immediately pour it into the hole, and tamp and pierce each layer in order to avoid the formation of hollow air cavities.

A beautiful and durable fence will turn out if, before pouring, it is imperative to check the evenness of each pillar with a plumb line.fixed in the hole as long as it can be corrected in wet concrete. The installation of the profiled sheet cannot be started until the final hardening of the concrete mixture has occurred. There are different opinions about the time when this will happen. In warm weather - about a week, in cold weather - a month can pass.

For the installation of a fence made of corrugated board, see the video.

The comment was sent successfully.