How to choose concrete fence posts?

When arranging a suburban area, one of the most crucial moments is the installation of a reliable and durable fence. Strong supports are required for any type of fencing. This type of fence supports are, first of all, concrete pillars.

Advantages and disadvantages of concrete supports

Concrete fence bases are traditionally considered the most reliable, due to a number of their advantages:

- Durability. Concrete fence posts have a very long service life and are guaranteed to last for several decades.

- Strength. Concrete supports are highly durable.

- Simplicity in processing and installation.

- Wide range of designs. The appearance of concrete pillars can be easily changed by applying different decoration materials. You can use paint, plaster, decorative stones.

- Easy to install. Owners of country houses can independently install concrete supports for the future fence. You do not need to contact specialists, since the installation of poles does not require professional skills and abilities.

Any product has its drawbacks. Concrete poles are no exception.

Minuses:

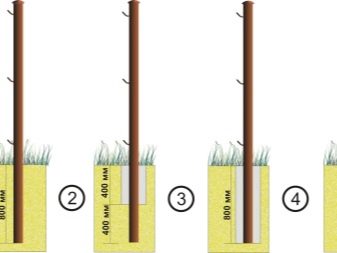

- For the correct and reliable installation of concrete fence posts, first of all, a strong foundation is required. The work of burying the foundation into the ground can take quite a long time. If you do not pay due attention to the quality of the foundation, then the fence may soon deform or completely fall.

- When self-manufacturing concrete pillars, it is necessary to carefully compact the concrete during pouring in order to avoid the appearance of air accumulations.

The positive characteristics of concrete fence posts more than cover their disadvantages.

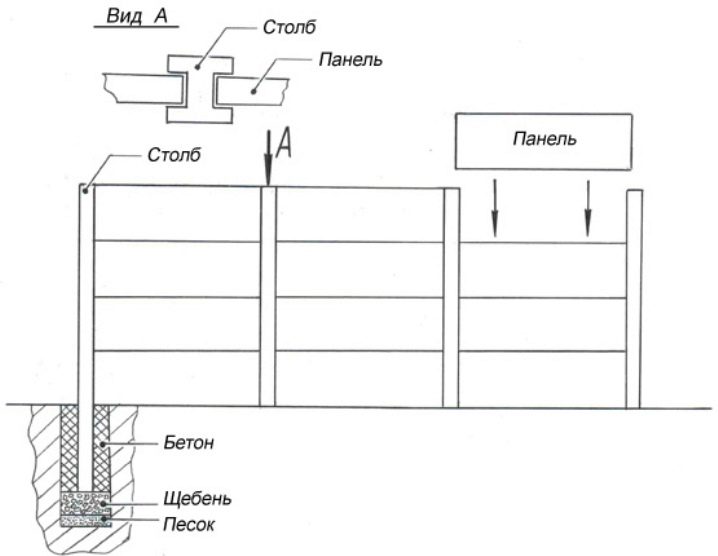

Installation technology

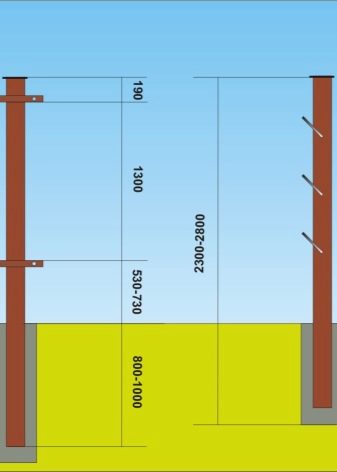

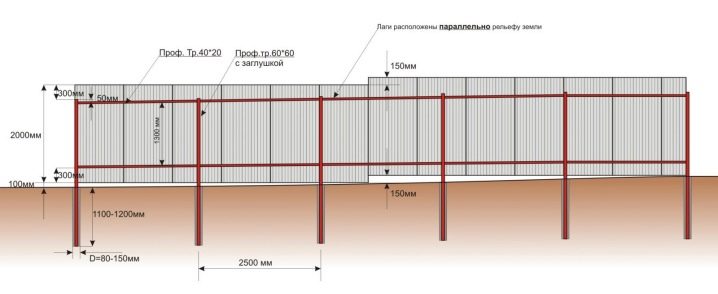

In the process of installing concrete supports for a fence, three main stages can be distinguished:

- First you need to build a formwork.

- Reinforced iron rods are installed.

- Pouring with concrete mixture is in progress.

Before proceeding directly with the installation of concrete posts, it is necessary to carefully prepare all the necessary tools, which cannot be dispensed with in the process.

In work, as a rule, you need:

- Wood or plywood boards.

- Metal fittings.

- Polyethylene film.

- Welding machine.

- A set of screws.

- Hammer.

So, after all the tools are prepared, you can proceed to the first stage of installing concrete supports, namely, the construction of the formwork.

This process requires high attention, since it depends on it how even and correct the future pillars will be. The simplest and most common formwork construction option is a wooden box formwork.

The work on the manufacture of such a box is carried out in certain stages:

- To begin with, from ordinary wooden boards or pieces of plywood, you need to cut parts for three sides of the formwork. The formwork itself should be made depending on the size of the future supporting structure.

- Next, you need to fasten three sides of the formwork and two ends to each other, and the upper part must remain open. This is done for future pouring of concrete with mortar. It is recommended to fasten the formwork with screws, which then, during the process of disassembling the form into parts, will be easy to remove.

- Next, you need to tightly fit all the elements of the form with each other and cover the structure with plastic wrap. It is recommended to do this to increase the waterproofing of the formwork when pouring concrete.Sometimes plastic is used instead of polyethylene, which further increases the level of waterproofing and does not allow the concrete mixture to flow out of the mold.

The use of reinforcement is important to give the pillars increased strength. A post made of pure cement without reinforcement cannot always provide the proper stability of the future fence. Attention should be paid to the quality of the concrete mix.

For the manufacture of a frame from reinforcement, some features should be taken into account:

- Four iron rods should be placed along the formwork structure. The recommended diameter of the rods is 12 to 16 mm.

- A short reinforcement is also needed, which will be located across the future pillars. Their diameter will be approximately 8 to 10 mm. Cross rods should be spaced from each other at a distance of 5 to 15 cm.

- When installing reinforcement into the structure, it is worthwhile to provide for a gap between the bottom of the formwork and the reinforcement, which should be about 2 cm. This is done so that the concrete mixture can completely hide the reinforcement.

After the construction of the formwork and the frame from the reinforcement rods, it is necessary to mix the concrete mixture. Three main ingredients should be used in the preparation of the solution:

- sand;

- water;

- cement.

You can stir the solution manually or use a concrete mixer, which will be much more convenient and will save energy.

Next, you need to go directly to the process of pouring the solution into the formwork frame.

To avoid the appearance of air voids in future pillars, the mixture must be poured slowly and carefully.

After pouring, the structure is covered with a board on top and left for 7 to 9 days to allow the mixture to completely solidify.

Self-production of reinforced concrete fence posts is a significant cost savings and personal confidence in the reliability of the structure.

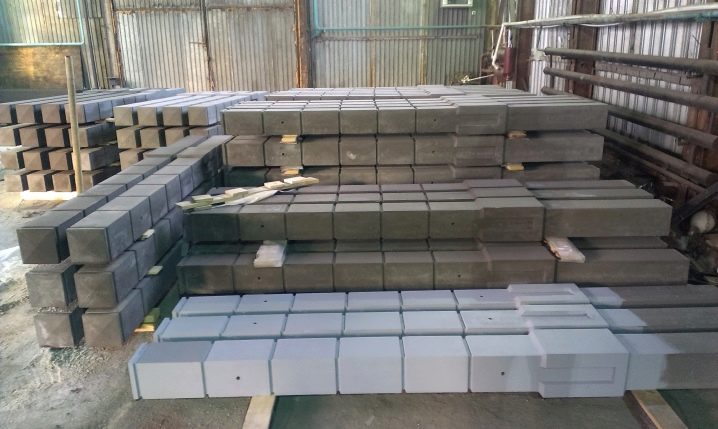

Also, quite often, the owners of country houses acquire prefabricated structures that have a number of positive qualities, in particular:

- low cost;

- ease of installation;

- durability;

- saving time and effort.

The main distinguishing feature of precast concrete columns is the quick and easy installation that anyone can handle. There is no particular difficulty in installing a precast concrete structure.

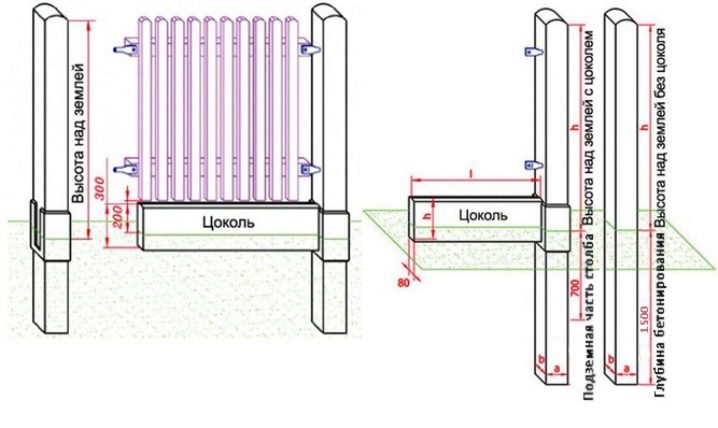

To install prefabricated pillars, you must first fill the foundation. A metal pipe or several rods of reinforcement is used as the core of future pillars.

Prefabricated blocks are fastened together with a concrete mixture. After that, the entire internal cavity of the column is poured with concrete.

Decorating

Quite often, concrete foundations for a fence are not just a house fence, but a kind of decorative structure. There are a lot of design options. The main thing is to approach the decor of the concrete structure creatively and with imagination.

When painting reinforced concrete pillars, the following types of compositions are often used:

- epoxy;

- acrylic;

- rubber;

- polyurethane.

To apply epoxy paint to concrete, it is necessary to carry out preparatory work on the surface of the pillar. This paint has a long-lasting color that is difficult to change with re-painting.

A distinctive feature of acrylic paints is their environmental friendliness. These paints have a fast drying time, are moisture resistant and can be applied in one coat. Acrylic reliably protects the concrete surface from corrosion. This paint can be applied to the surface either with a roller or with a brush. The full drying time for acrylic paint is 14 hours.

Rubber paints are a fairly new product that is highly moisture resistant. Such compositions can be applied even to a damp surface, but this must be done in several layers.

Polyurethane paints are highly resistant and have chemical and mechanical resistance.The only drawback of such paints is the long drying period, which can be from 2 to 14 days.

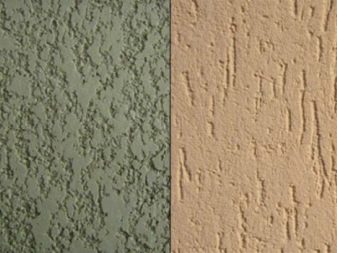

Plaster is often used to decorate concrete posts.

In this case, it is worth highlighting several types of plaster:

- lime-gypsum;

- mosaic;

- mineral;

- decorative.

A feature of lime-gypsum plaster is its complete environmental friendliness. Lime and gypsum plaster is very resistant to mechanical damage and the appearance of mold or mildew.

Mosaic plaster contains fine stone chips. The plaster is guaranteed to remove all mechanical damage.

The composition of the mineral plaster contains a cement-lime mortar.

Decorative plaster gives concrete poles a stunning appearance. Decorative plaster is very strong and durable.

It is also very fashionable to decorate concrete structures with plastic panels or decorative stone. Plastic panels are presented in a wide range of colors and patterns, and decorative stone gracefully imitates the surface of a natural material.

An equally fashionable trend is the decor of the fence and reinforced concrete pillars using mosaics.

Usually, flagstone is used for mosaic decoration, which is easily cut into the necessary parts. Mosaics can also be presented in a wide variety of colors and patterns.

Such a decorative element as decorative brick, which appeared on the market relatively recently, is an excellent decoration for concrete fence posts.

Such bricks can be of several types:

- smooth;

- "ragged";

- angular;

- semicircular.

The laying of decorative bricks is no different from the standard one.

Such a range of materials for decoration will help to give any shape, color, sophistication and creativity to gray and nondescript concrete pillars. And besides, modern design materials not only decorate the surface, but also give it additional strength.

For information on how to choose concrete fence posts, see the next video.

The comment was sent successfully.