Rack wood splitters: device and do-it-yourself manufacturing

Wood splitters are considered a fairly convenient device that greatly facilitates the work of harvesting firewood in private houses and in summer cottages. Wood splitters come in a wide variety of designs, rack and pinion are considered the simplest. Let's give a brief overview of the main characteristics of this device.

Appointment of wood splitters

If you are the proud owner of your own country house, then you probably know well how hard it is to chop wood, swinging a heavy weighty ax. However, progress does not stand still, so nowadays the work of harvesting firewood can be significantly facilitated. To do this, use special machines called "wood splitters".

Of course, not everyone has a need for such a technique. If you chop wood once a month, then an ordinary cleaver is enough for you, but there are categories of homeowners who cannot do without a mechanical device. First of all, these are people who permanently live in houses with stove heating, fireplaces or solid fuel boilers. Such equipment is necessary in wood-burning boiler rooms, and, of course, do not forget about lovers of the Russian bath - after all, before they take a good steam, they will certainly need to stock up on firewood to kindle the hearth.

Thus, a wood splitter is suitable for everyone who, for one reason or another, is forced to periodically harvest firewood. The device will be useful if the owners of a private house are women, elderly people or physically weak men. One of the most popular models of wood splitter is rack and pinion.

Peculiarities

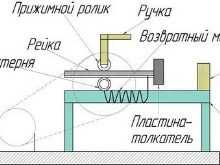

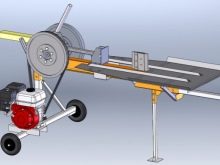

Wood splitters are very reliable and efficient, they are characterized by high speed of operation and simplicity of the mechanism. The principle of operation is generally elementary - the chocks are placed on the working surface, after which the pusher is activated using a lever. It moves along the rails and with effort pushes the workpiece onto a rather sharp knife, which is located at the very end of the unit.

All manipulations take a few seconds, and as a result, the log is split into several parts.

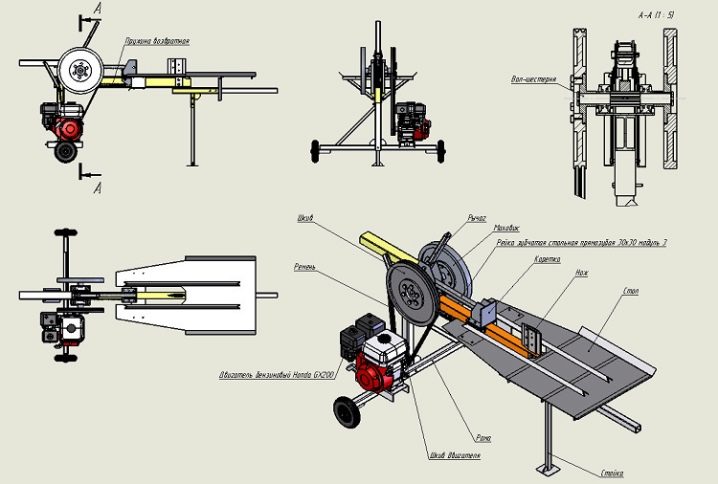

The principle of operation of such a wood splitter is based on the use of a rack and pinion gear:

- the gear rack is mobile, it is driven by a gear pressed onto the shaft of a reduction gear or a belt drive pulley;

- the rail is fixed on the bed, where the chock is laid;

- the gear meshes with the rack using a special control handle;

- all these parts are mounted on a strong stationary frame, while a cleaver is attached to one of its ends;

- there are guides on the frame along which the toothed rack moves;

- the rack is returned to its original position by means of a return spring.

The structure can be driven by an engine of absolutely any type - gasoline, diesel or electric, in addition, it is often driven from the power shaft of an agricultural tractor or a car wheel, that is, from any motor that produces torque. At home, some craftsmen even install an engine from a washing machine or an engine from a chainsaw.

Advantages and disadvantages

There are quite a few advantages of the wood splitter, regardless of whether a factory-made model is used or the device is made in artisanal conditions. The advantages include:

- ease of use;

- long service life;

- the ability to work with a 220 and 380 V drive;

- the tool works in all weather conditions, except, of course, in an open area in the rain (the electric motor can burn out);

- the efficiency of the wood splitter is unchanged regardless of the type of wood;

- great power of the split;

- provision of the tool with double protection, as well as a safety clutch and a special thermal relay;

- low energy consumption - no more than 1.5 kW per hour (gasoline consumption is only 500 grams);

- high speed of work - a log of about 70 cm in length splits in 1-1.5 minutes;

- performance comparable to that of hydraulic equipment ..

At the same time, the cost of such wood splitters is quite democratic, and with some technical knowledge, such a device can be made even at home.

Of the shortcomings, one can only note the inconsistency with European safety standards, but with proper use and compliance with all operational standards, the risk of injury is not higher than when purchasing more expensive imported and units. And certainly working with an inertial rack and pinion splitter is fraught with much less dangers than chopping wood with an ax manually

How to make a wood splitter

To make a do-it-yourself rack-and-pinion wood splitter, it is extremely important to draw up a high-quality drawing and a layout diagram of the tool parts. It is necessary to decide in advance on the material and calculate the amount required for work.

For the manufacture of the frame, an I-beam, a professional pipe, as well as a channel or steel corners are used. All these parts are assembled into a single structure so that the device stands firmly enough and does not swing.

An important part of the wood splitter is the piston, which ensures high-quality pushing of the wooden block during the operation of the installation. To this end, the required pushing force should be calculated so that you do not have to catch the halves of the chocks at the exit, and also do not harm yourself. You can search for such a part on the market ready-made, or borrow it from a jack of a car, tractor or other medium-sized agricultural machine.

For installations that use an electric motor as a drive, it is best to install a safety clutch to improve safety. It is advisable to pick up a cleaver with a four-cutter, in this case the log is immediately split into 4 equal parts.

It is better to equip the log splitter not with a vertical, but with a horizontal way of laying in the form of a gutter, due to which the optimal movement of the chock to the cleaver is achieved. As for the nozzle, alloy steel is traditionally considered the best cutting material, so it is better to choose a well-ground metal surface as a cutter.

Operating rules

Before starting work, it is necessary to prepare the logs and the wood splitter itself. The unit is installed on a flat, solid surface, and if the tool is equipped with transport wheels, they must first be removed.

Make sure the unit is free of any defective parts or damage to the hydraulics. If you find any violations of integrity, you should contact the service center or, if you are working with a homemade tool, replace the part with a new one. The logs should be used dry, in this case it is easier and faster to split them. It is important that there are no nails, bolts or staples in the chocks that could damage the cutterbar.

The log is placed in such a way that it is held as securely as possible by the guides, after which you should press the start button and wait a few seconds - a soft switch is needed so that the engine reaches the highest speed, only after that you can press the second lever, which activates a piston that pushes the log towards the cutter. Pay particular attention to the fact that the start button, like the control lever, must be held down during the split. If one of these is released, the piston immediately returns to its original position. This is a kind of protective system - if during operation the plant operator needs to fix something, then he cannot do this without turning off the entire mechanism.

If you are unable to split the log, you should try turning it over and manipulating it on the other side. If the chock does not cut, set the log aside, as the engine will overheat, which is fraught with serious system breakdowns.

When working with a rack-and-pinion log splitter, regardless of its type and manufacturing method, you should adhere to the safety instructions. Keep in mind that if the piston moves too quickly or does not work correctly, then during the splitting of the wooden blanks, you can be injured. If the wood is quickly fed to the cutting blade, the tool can jam, which leads to its breakage.

When installing a moving knife, you should take care of its correct location at the design stage of the equipment. The place must be hidden from the working person, otherwise injury cannot be avoided. If the workpiece is jammed, you do not need to knock on it, your hands during the operation of the unit should be as far as possible from the piston and the cutting blade.

In the next video you will see the first test of the wood splitter.

The comment was sent successfully.