Wood splitter gearboxes: features and subtleties of choice

Wood splitters are very useful devices in everyday conditions. They should not be underestimated as the convenience and safety of harvesting firewood directly depend on such devices. Much attention should be paid to the reducer for the wood splitter, which is an important element of the system.

How to choose?

Choosing the right gear unit means ensuring the overall reliability of the system and its long-term operation. If you make the slightest mistake, you will have to spend money at the most important moment to repair or replace any part. In the worst case, you will have to change the elements interconnected with the broken part. Therefore, it is very important to use the help of professional designers and engineers.

They pay attention to a variety of factors:

- placement of the gearbox in space;

- its mode of operation;

- general load level;

- the temperature to which the device is heated;

- the type of tasks performed and the degree of their responsibility.

There are many varieties of gear units. If you choose the right element, the worm gear will work for at least 7 years. The service life of cylindrical systems can be 1.5-2 times longer.

However, it is not always possible to obtain advice from engineers in practice. In this case, you can be helped out by the simplest recommendations, which will be discussed below.

About types of systems and not only

When preparing to assemble a mechanical or hydraulic log splitter, you need to start by preparing the kinematic diagrams. They will show which types of gear units are worth using.

- In cylindrical horizontal apparatus the axes of the input and output shafts are located in a common plane, but on parallel lines.

- Similar in structure and vertical gearboxes - only the orientation of the main plane is different.

- Have worm gearboxes with one step, the axes of the shafts intersect at right angles. Two-stage worm gearboxes are designed with parallel shaft axes in mind. They are deliberately placed in different horizontal planes.

- Also of a special type are bevel-helical gearboxes... Among the two shafts, the output is of increased importance. It is his orientation in space that has a decisive influence. In worm-type devices, one type of gearbox can be installed for all orientations of the output shaft in space. Cylindrical and tapered versions almost always allow the output shafts to be placed strictly horizontally. Exceptions are rare, for the most part they are achieved by design tricks.

With the same dimensions and weight, cylindrical mechanisms are 50-100% more efficient than worm analogs. They last that much longer. That is why (for reasons of economic efficiency) the choice is quite obvious.

Other nuances

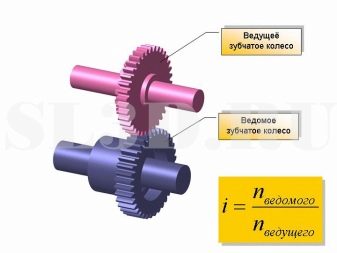

Is of great importance gear ratio of the gear unit... It is determined using information about the number of turns of the electric motor and the required torsion parameters of the output shafts. The indicator established as a result of the calculation is rounded to the nearest typical value. It is important to note that the motor shaft, and therefore the output gear shaft, must not rotate faster than 1500 times per minute. Within these limits, the parameters of the motor are selected in accordance with the general requirements for the device.

The required number of steps is set according to special tables. The initial indicator for the determination is just the gear ratio.If the GOST on the gearbox indicates that it will be used "sporadically", it means that:

- the maximum load will be 2 hours for every 24 hours (no more);

- 3 or 4 switches are made per hour (no more);

- mechanical movements are performed without impacts on the mechanism itself.

The so-called cantilever loads on the shafts are also determined. They must match the level specified in the accompanying documents for the gear units, or even be less. It is necessary to take into account both the average level of work over an hour (in minutes), and the torque. Since in self-made designs all these nuances are difficult to predict, it is not recommended to make gearboxes from the rear axle and similar auxiliary units... The quality of their work turns out to be unsatisfactory in comparison even with the "average" factory devices.

The geared motor is preferable if the compactness of the drive comes first. Over 95% of structures of this kind are designed for arbitrary placement of the output shaft. In the step-by-step assembly instructions, it is also noted that there is no need to use couplings, joining the motor and the gear unit. But you need to understand that such devices are expensive. In addition, each time an individual order must be sent with the required parameters.

By self-assembling an analogue that requires the use of couplings, you can easily reduce costs by 10% or even 20%.

Models

- When assembling wood splitter, a single-stage gearbox is often used. RFN-80A... Its characteristic feature is the placement of the "worm" on top. The developers assumed that their product would be used in low-performance industrial devices. The helix is oriented to the right. There is no fan inside the unbreakable cast-iron case, the efficiency ranges from 72 to 87%.

- Modification Ch-100 works successfully under constant and changing, monotonous and reverse load. The design ensures that the shafts can be twisted in any direction.

- For screw wood splitter can be used reduction gear reducer... This type of element is highly reliable. The reason is simple - the metal jagged parts are extremely tightly connected to each other. It will take almost extreme effort to break this hitch.

An overview of a homemade wood splitter with a gearbox is waiting for you in the video below.

The wood splitter is a good thing. I have the same - I cut 80 cubes of birch and nothing broke.

The comment was sent successfully.