Diy wood splitters: assembly instructions

Chopping wood is a useful activity for any physically strong healthy man. But sometimes there are large volumes of firewood, which must be prepared in a short time, in this case they use a special tool. A wood splitter is a device that is difficult to do without when you have to chop massive wooden ingots.

Features of homemade models

The wood splitter is especially necessary in private households, where you have to heat the house using firewood. You can make such a tool with your own hands, it is not difficult and will save a significant amount of money. Working with a solid tree is a rather risky business, you can get injured, so you should use a good tool, observing the necessary safety regulations.

Mechanical units that help to split wood and heavy logs tend to store energy, they are economical and easy to operate. There is no need for muscle strength in working with such devices. The units can handle any kind of logs and wood ingots. They work in push mode and can handle logs up to 35 cm long, no physical effort is required.

Push action devices have an internal combustion engine drive, and can also be connected to an electric motor. They are not cheap, but with their use, muscular efforts that must be expended are almost completely eliminated. Using this device, you can heat a house up to 350 square meters, while frosts can be Siberian, up to -35 degrees Celsius.

This unit is safe; among the shortcomings, one can point to a rather complicated design and high energy consumption.

The return stroke of the pusher is usually no more than 7 centimeters per second. In a few hours, more than half a ton of firewood can be prepared for one person. You cannot work with damp wood; it is recommended to put wooden blanks in a woodpile under a canopy in the warm season. In three months, the tree will "fit" to the desired condition. Raw wood does not provide enough heat, the thermal conductivity is much lower (by 25%), the cleaver often gets stuck in it, and it is sometimes extremely difficult to extract it from there. A homemade wood splitter can be made no worse than a factory one, that is, it will have horizontal and vertical feed of the workpiece.

For orientation, it is worth saying what the approximate monetary savings can be:

- a solid diesel-fueled unit designed for splitting ingots 25 cm in diameter costs from 20 thousand rubles;

- a machine that can “straighten” with blanks up to 35 cm, splitting them into 4-5 fragments, costs about 30 thousand rubles.

Specifications

The simplest construction of a wood splitter is a cleaver ax. It takes some practical experience to work with it. For experienced woodcutters, the cleaver can be the main tool when processing massive wooden blanks, the size of the ax of this tool is up to one meter. In recent years, the cleaver has been made from innovative materials, which allows it to be used more efficiently in the labor process.

The handle is made of lightweight, durable fiberglass material, allowing you to work more efficiently with this tool.For two thousand years, while the cleaver ax has existed, it has been continuously improved. The modern fiberglass hatchet completely eliminates vibration, painful recoil in the palm.

To harvest firewood in large quantities, push-type wood splitters are usually used. They have a rack or hydraulic pusher. A similar device pushes a massive wooden blank onto a cleaver, which, in turn, splits it into several small pieces. The feed rate of the workpiece is about 5 centimeters per second. Vertical wood splitters are more durable and more compact. The disadvantage of this device is that there is a risk of ejection of a workpiece in which there are such "difficulties":

- many layers;

- many knots;

- there are various wrong cuts.

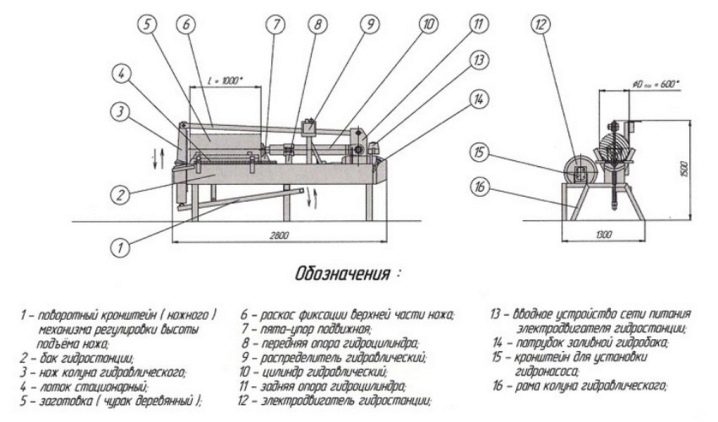

The horizontal log splitter is safer. The employee does not run the risk of falling under the flying chips, because its speed is sometimes very high. The vertical unit has a circular scattering of fragments, therefore, from a safety point of view, there are questions about this unit. Hydraulic wood splitter:

- productive;

- spends a minimum of energy;

- safe to operate

Of the shortcomings, it should be pointed out: to work with such a device, you need some experience. And also under heavy loads, liquid can flow out of the apparatus. The unit is simple to maintain, spare parts for it can always be found on the market.

The hydraulic wood splitter does not have a return spring, and also has a rather long switching time - about 0.55 seconds. The time span is quite significant, because the workpiece can split and disintegrate into many fragments. Such wood splitters have a common drawback: their engine runs through a fluid coupling and sometimes cannot cope with the loads. The engine usually runs in standard mode, while consuming little fuel. A gearing is attached to the flywheel (it is usually hydraulic, there is also a fractional one). This lever is a clutch with a pusher, which provides the supply of the chock to the cleaver knife.

There is enough energy to split almost any piece of wood.

Tools and materials

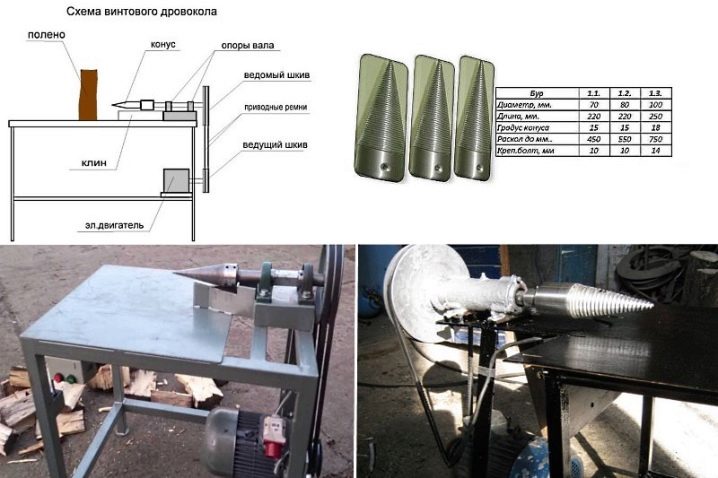

To create a screw cleaver you will need:

- power plant from 1.5 kW;

- shaft with fitted bearing;

- drive belt;

- threaded cone;

- metal 6 mm thick;

- corners 6, pipes 45 mm.

You will need tools:

- jigsaw;

- welding machine;

- turbine;

- screwdriver;

- screwdriver;

- Scotch;

- hammer;

- nippers;

- pliers;

- tape measure and triangle ruler.

How to do it?

Before starting work, it is necessary to prepare drawings and assembly instructions. A simple wood splitter with an electric motor can be assembled at home. Indicative in this regard is the hydraulic wood splitter, which can be made in the garage. The hydraulic system can be supplied from a mini-excavator or some other equipment. The performance will be determined by the splitting force:

- 20 cm by half - 2 tf;

- straight layer - 2.7 tf;

- 25 cm - 2.4 tf;

- 30 cm in 4 parts - 4 tf;

- 30 cm in 8 parts - 5 tf;

- 40 cm in 8 parts - 6 tf.

The power of the hydraulic pump is determined by the feed rate, which on average is 4.5 cm. Then the efficiency is calculated and the engine is selected, its stock should be 15% more.

And also fittings are selected with a margin;

- hose;

- valve;

- dampers.

An important working element is the cleaver itself. It is made of durable metal (auto spring or rail, for example). The workpiece is usually met by a vertical knife that is sharpened on a straight line (symmetrical wedge). The horizontal knife stands a little further (18 cm), it is spent on the upper oblique wedge.

The vertical knife is placed from below for better safety work, the height is about 35 mm, while the tool protrudes by 25 mm. This design will allow you to work with complex wooden elements, provided that they are placed flat sideways at the bottom. The sharpening angles are as follows:

- the vertical knife is designed for soft wood - 19 degrees (three knife thicknesses);

- for hardwood (including birch) - 15 degrees (3.8 knife thickness);

- horizontal knives - 16 degrees;

- the pricker has an angle of inclination of no more than 26 degrees (minimum 20 degrees), the thickness of the knife is 2.6;

A rack-and-pinion log splitter is simpler, it is cheaper than a hydraulic unit (it costs no more than 20 thousand rubles). Making it yourself is not very difficult. The pusher is fed using a toothed rack, the transmission connection to the shaft works in such a way that the movement occurs no more than 4.5 cm per second. To do, you need elements - just disassemble the old jack. The rack-and-pinion splitter has no hydraulic components, and its maintenance takes a minimum of time.

Such a unit, from a safety point of view, is more preferable. The scheme of work is as follows: it acts when the lever is lowered, then the return spring element will raise the rail and fold it back. The disadvantage of such a unit is that with a decrease in the feed rate, the stop grows rapidly, and then also unexpectedly drops to zero. If there is a cavity or some other flaw in the workpiece, the unit will be subjected to too strong a load, this can happen spontaneously, which can provoke deformation of the machine or even its breakdown.

The hydraulic drive always works softer, the largest stop ratio occurs when there is a feed rate that approaches zero. If a workpiece that is too strong gets into the feed of the hydraulic unit, it will be pushed onto the cleaver non-stop, which can lead to damage. For a rack and pinion wood splitter (based on all the above remarks), a more powerful engine is needed. To calculate its power, you can simply shift the splitting forces that exist for a hydraulic drive: a pig with a diameter of 20 cm - 2.6 tf, while the efficiency will be about 0.87.

Often too thick shriveled bark interferes with the movement of the workpiece. As a conclusion, it can be noted: rack and pinion units are appropriate when the volume of work is relatively small, the work is done using muscle strength.

For small pieces of firewood, a vertical screw log splitter may well be suitable. This device has a small performance, it is not afraid of various flaws in wood blanks. An electric engine for its operation may be suitable for a low-power, only 2.8 kW - from a washing machine, with a drive on a pulley. With a low-power engine, such a unit will be able to "cope" with elements up to 42 cm in diameter and up to 65 cm high. To create it, you will need an engine from a washing machine, the rotational speed of such a power plant may well be suitable. The disadvantage may be that by mounting the cleaver directly on the engine shaft, the engine housing can lead and it will break.

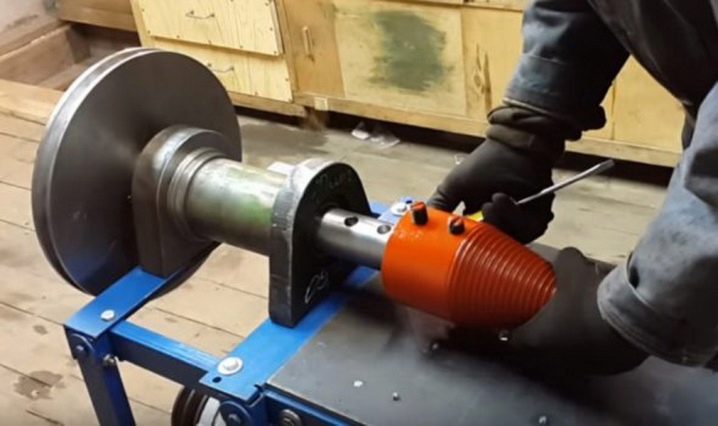

In the work, the main role is assigned to the nozzle in the form of a cone, which has a thread and rotates at a speed of 160-1550 rpm (the operating frequency is usually 300 rpm). The carving is done left-handed due to the fact that people for the most part are right-handed, their right hand is physically better developed.

The workpiece on a screw cleaver enters it along the vertical plane. During movement, the workpiece (its movement) gets better with hands. This formulation of the question does not have the best effect on the level of safety, therefore, one should take into account the fact that a screw log splitter is a device that is dangerous. The worker is required to monitor constantly so that too little material remains under the right hand. If the cleaver gets stuck, the process of winding the workpiece will take place. To prevent such incidents from occurring, you should mount a spacer under the cleaver.

The assembly and operation of the screw unit can be influenced by the rationality of the design, as well as the location of such units:

- wedge stop;

- drive pulley;

- work of the main shaft.

And it is also important what shape the cleaver itself is, how it is sharpened, such parameters will certainly affect the operation of the unit itself. The wedge stop is also important, it determines the safety of the unit and affects the performance and reliability. If the emphasis is chosen incorrectly, then problems will arise with the engine, the functioning will occur with a high voltage of the power unit. The performance will be noticeably lower. It is impossible to leave the cleaver in the air without the presence of a lower stop. The wedge stop is attached to the base on the right. Moreover, its length can be such that the nose is larger than the length by 1 / 4-1 / 2 of the thread distance.

The stop parameter corresponds to the splitter diameter in a similar section (in this case, 4 heights of the threaded part are subtracted). The distance between the shank and the stop is about 1.8 mm, however, if the gap is 0.8 mm, then this will be even better. The cleaver will initially "interfere" a little, but after a short time, grinding will occur, and the product will serve for a long time.

The vertical stop is 2/3 of the shank. For 76 mm, the limits are limited to 52-62 mm. Pulling the workpiece has to be intercepted manually, after the cleaver has entered the tree quite deeply. If the cleaver has already entered too deeply into the material, it will be impossible to hold it with bare hands. The tucked-up bottom will hit the side of the stop. In this case, damage and defects are possible.

It is necessary to make the unit in such a way that the cage and the main shaft drive are made according to the instructions, in this case nothing will happen and there will be no damage. In a screw wood splitter, the inertial impulse for rotation is carried out by transmission through a pulley. In this case, the pulley should slip if a "plug" occurs, otherwise an accident is inevitable.

In this regard, transmission with the help of a chain is more rational and practical, "plugs" become noticeably less. The chain itself has a lot of weight, because the transmission is more rigid and allows you to overcome "obstacles". If the workpieces have too many knots, then you will need to install a drive, which is presented in the form of a powerful driven pulley.

There is a carrot screw, this unit really resembles a root crop. The unit is simple in device and assembly, you can work with it when harvesting a small amount of firewood. And also this device can cut wood, so the splitting with a screw provides a sufficient amount of sawdust. On the farm, this is sometimes in demand if there is a poultry house on the territory that needs to be heated.

A wood splitter with a sliding cleaver is another option. The shoulder is taken into account 1.6 meters. Overload can be up to 40 kg. If the wood splitter is stationary, then in this case it can work as an inertial lever, that is, it can be lifted by the handle and then lowered onto the workpiece with effort. If the cleaver is dynamic, then it can be easily moved along the lever, in which case it can be push. At the same time, the shoulder is significantly lengthened. The Lever Log Splitter has a number of features:

- it is best to use the Arrow cleaver, it is not difficult to buy it;

- the lever is held by a spring in a horizontal position;

- the spring must be well fastened so that it does not fly off;

- often the spring is passed into a moving pendulum guide.

If the mechanical unit is not attached to the base, then it is made with a diameter that is not inferior in size to the lever arm (a size is taken that is 2 times the size of a wooden blank). It makes no sense to create a "mechanic" with a fixed cleaver that slides along the guide. Even if you hit the cleaver with all your might with a sledgehammer, it will often jam.

A cone-shaped wood splitter is also often used, which in a private household (when relatively little firewood is needed) can cope with rather weighty ingots (up to 55 cm in diameter).The cone is made in the size of 82-148 mm, the angle of inclination is about 16 degrees if the tree has small layers, and 19 degrees if the layers are straight. The opening angle of 26-32 degrees changes by a third of the height of the cone. It is best to use a rack and pinion jack. A rack and pinion jack is preferable because it is very simple and reliable, not afraid of heavy loads. There is more work to do with a hydraulic device and it is more vulnerable when overloaded.

One more detail is important. The control rod of the cone splitter is usually made functional; in this case, reinforcement or a rod of steel grade St47 is used, with a diameter of at least 22 mm. The thread is made in the form of a trapezoid (sewer valves are often suitable, where the steering wheel is removed and replaced with a lever).

You can also make a wood splitter in the form of a saber with your own hands, such a device is also called a saber one. The lever arm here is not less than 0.9 meters, it is made of soft wood species (pine, birch). You can work with such a wood splitter only with soft tree species. And also in the dachas they put wood splitters of the lever principle of operation for the winter, which can break workpieces up to 35 cm in diameter. The performance of such a unit is low, but in order to chop wood for dinner, such a device is quite enough. With the help of the pedal, the sliding stop is raised, then it is released and pressed on the pedal, thus the workpiece is delaminated.

You can even make a wood splitter from a wheel, we will consider the technology below.

From the jack

A wood splitter can be made from a jack that is manually driven by physical force.

You will need the following materials:

- hydraulic jack;

- steel sheet 5 mm;

- channel or corner No. 8;

- primer;

- springs;

- bolts and nuts.

Tool list:

- Bulgarian;

- welding machine;

- drill;

- triangle ruler;

- marker.

It is important to properly fix the vertical mounts, they will bear the lion's share of the load. For these purposes, you will need a corner number 8 or an I-beam. Then a wedge is made, which cuts wood blanks. This element is made of steel or a corner. It is also recommended to sharpen the wedge well, then the work will be more productive. The jack will be placed with a bottom stand, which must be slightly raised above the base. To do this, you need to weld on a few flat pieces of sheet steel. The jack must be well secured so that it does not jump out during operation. The element is additionally fastened with clamps with nuts.

You will also need springs that will return the element to its original state. You should also make a reliable bed, which is best welded from steel. In order for the support base to be fixed firmly on the jack, a round pipe is additionally welded to it. And you will also need to weld the fasteners for the springs. The apparatus is mainly placed in a corner, it can be additionally "grabbed" with bolts to two walls.

From the rim

A wood splitter can be made from a wheel disc of a tractor or truck. Concrete can be poured into the cavity of such an element to build up mass. A vertical mount similar to a guillotine is welded to the central block. The disc rotates, and the "guillotine" falls and hits the plate, which is attached in the center. It is not easy to work on such a unit; it requires practical experience.

Security measures

During operation, safety precautions should be observed. The energy that is spent on splitting wood elements is quite significant. The spreading speed of the chips can be high. Before starting the drive, check all locking elements:

- bolted connections;

- joints;

- fastening the pulley;

- cable;

- engine mount;

- knives must be in good condition, without chips or signs of corrosion.

Long-sleeved clothing should be loose and dense and should also be:

- good work boots;

- gloves;

- glasses;

- headphones.

The equipment should be placed on a flat, stable surface that is “not afraid” of powerful vibration. A reinforced concrete slab is an ideal basis for basing such a unit. The machine can only process parts that match the format of the equipment. And a few more tips:

- when the machine is operating closer than three meters, it is not recommended to approach it;

- the working area should always be fenced off with a signal tape made of paper or PVC material;

- the equipment should only work under the supervision of an employee;

- during operation, you should carefully monitor that foreign objects do not fall into the unit;

- regular inspections and test runs should be carried out;

- all repair work is carried out with the engine disconnected from the network.

It is useful to change the drive belts. The old pulley "remembers" the trajectory of movement, over time it becomes rigid, which provokes unnecessary vibration.

For information on how to make a wood splitter with your own hands, see the next video.

The comment was sent successfully.