A gazebo from a profile pipe: types and step-by-step manufacturing instructions

A gazebo made of a profile pipe is a place where you can hide from the daily hustle and bustle, be alone, and relax. Such a structure can become a "highlight" of the entire site. Many people build gazebos for grapes - structures entwined with plants look very interesting.

Design features

From the name you can guess that profile pipes are used as materials for creating such a gazebo. The sections of such products are rectangular and square. Profiled pipes with these sections are very well suited for creating metal structures, especially in cases where the structure is being erected with your own hands.

The shaped pipes will provide the following:

- All structural elements are very easy to fit to each other, which greatly facilitates installation work. Products with a circular cross-section do not differ in this advantage.

- The construction of a professional pipe does not weigh very much, since its elements are hollow, but at the same time it is durable.

- The distribution of the load will be as even as possible.

- Even the simplest design will have an aesthetic appearance.

- Construction work will be carried out very easily and in the shortest possible time.

Profiled pipes are a material that can be called truly universal. Such pipes are used, for example, for roof beams, benches, tables. If it is necessary to make the design look more interesting, then it is better to use professional pipes with different sections.

It must be taken into account that the diameter of the racks must be made in such a way that the structure as a result is distinguished by its strength, reliability and durability. Other structural elements may be smaller.

It is better to create pillars for support from a square metal profile. Rectangular products should be used to create elements that are not subject to significant mechanical stress. These include, for example, fences, battens and other structural elements.

When carrying out installation work, you need to work with various electrical devices, for example, with a grinder or an electric drill. You should be aware of the nuances of using such tools. It is possible that you will also have to use a welding machine - the structure will turn out to be more accurate if you use it, and not nuts and bolts.

Structures made of iron professional pipes are distinguished by fire resistance, which cannot be said about wooden structures. Therefore, it is quite possible to install a brazier in such a structure, because if a fire occurs there, it will not affect the structure in any way.

Garden gazebos from a profile pipe also have disadvantages. These include, for example, the lack of thermal insulation. However, such designs are usually intended for use in the warm season, so this drawback cannot be called serious. In addition, the surface will need to be regularly and carefully looked after - otherwise, corrosion may develop on it.

Varieties and methods of creation

Gazebos for summer cottages are very different: round, eight- or hexagonal, rectangular.

The metal frame is installed in one of two ways:

- Vertical pipes are concreted into the ground. After that, the structure is attached to these supports.

- A monolithic slab is poured, which is quite rare, or a columnar or strip foundation is being erected. The overall structure is created separately. The frame is fixed after the installation of the racks.

It's hard to say which way is better.The first method is more reliable fastenings, because the pillars are concreted. In this case, you also have to give less money, because the lower strapping and foundation will not be needed. However, a gazebo without a floor is an exclusively summer option. In the construction of a professional pipe on the foundation, the presence of a floor is provided initially.

Assembly diagrams

Usually, metal elements are connected to each other using a welding device. Such work provides significant strength of the welded arbor and is carried out fairly quickly. However, it should be borne in mind that this option is practically not used for an open summer gazebo. In this case, it is better to connect the elements to each other using bolts. If necessary, you can re-carry out installation work or dismantling, which will not work if the structure is welded.

Most often, a collapsible structure is a metal frame, which is covered with some kind of material. Many people use an awning for this.

If the structure is collapsible, then it is better to break the frame along the edges. For a quadrangular gazebo, separate contours are created, there should be four of them. Using jumpers, you need to connect them to adjacent elements. In a similar way, octagonal and hexagonal structures are made.

What materials to choose?

It is recommended to stop the choice on profiled pipes with a wall thickness of at least 2 mm. You should not choose overly thick products. In stores, they are most often offered by kilograms, so they are usually quite expensive.

Even if it is necessary to use round pipes, it is still recommended to focus on the wall thickness indicated above. Such products are more difficult to install, but it is still quite possible to cope with this work if you have certain skills and experience. Round pipes are less expensive than rectangular ones.

Some people prefer to use metal corners. However, such a product must be thicker than the pipe (the recommended thickness is from 25 to 30 mm), since the corners are less rigid. These structural elements are very well suited for cladding.

Profiled corners and pipes are not only steel, but also aluminum. Aluminum is lighter than steel - this advantage is very important when creating a collapsible structure. However, higher prices are usually set for such materials - not all owners of summer cottages can afford such a gazebo.

Construction works

Below is an example of creating a gazebo 5.4x3 m (gable roof). Construction work is carried out in several stages, each of which is very important. For this reason, it is not recommended to skip any of them.

During construction, the following tools and materials may be needed:

- bitumen;

- stakes made of wood;

- professional pipes 4x4 and 4x2 cm;

- primer material;

- Bulgarian;

- sand, cement, crushed stone;

- level;

- sledgehammer;

- square;

- welding device;

- hand drill.

So that during the implementation of construction work you do not have to worry about purchasing the missing device, you should prepare everything in advance. After that, you can start creating the structure.

Markup

First, it is recommended to thoroughly clear the area where construction work will be carried out. It is necessary to get rid of the debris and remove the sod. In the place where one of the corners of the structure will be located, a peg made of wood should be installed. Then you need to designate other corners and separate the site for construction with a rope. Be sure to check the diagonals of the resulting rectangle - they must be equal to each other.

The long side must be divided into three parts, the short side must be divided in two.

Pits and installation of supports

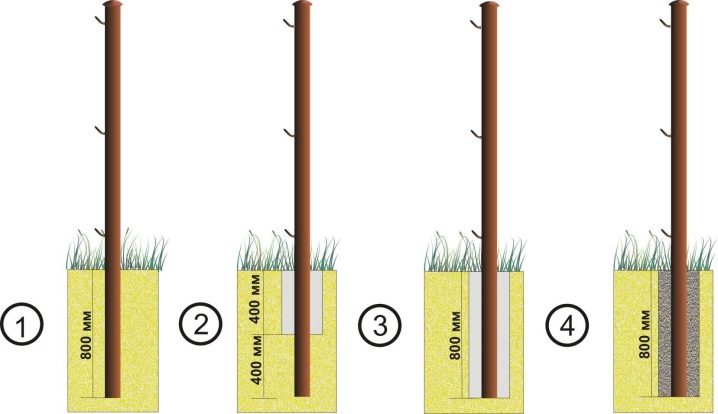

After that, you need to prepare pits for the support pillars. They should be quite deep - about 50 cm. If you want the soil to remain fairly dense and stable, you should use a hand drill.There should be ten holes. The pits must be made of the same depth and diameter.

It is recommended to apply liquid bitumen to one third of the height of the supports, after which the columns must dry. Then the impregnated ends of the supports should be placed in the pits. It is necessary to make sure that the pillars are as level as possible, and with the help of a sledgehammer, they should be hammered 80-90 cm.After that, you need to make sure again that the supports are level. Then you should cover them with soil and pour concrete mixture.

To get rid of air bubbles, you need to pierce the concrete in several places using a metal rod. After that, it is necessary to make the surface as flat as possible. Then it is recommended to carry out the strapping - horizontally attach the professional pipe to the posts along the upper edge at a distance of about 0.9 m from the ground.

Roof frame

The roof frame should consist of cross members, ramps and a base. It is also created using a professional pipe. It will not work to place such a frame on the supports on your own, so you need to turn to someone for help. It should be lifted and carefully installed on the harness. Then it is recommended to make the frame as level as possible and attach it to the corners of the structure using a welding device.

Weld spots must be cleaned, then primed and painted over.

Floor

The floor covering can be made of paving slab material. This is the simplest option, although other materials can be used, such as cement screed or boards.

The soil must be compacted and leveled. Using a spirit level, check if the surface is sufficiently level. If necessary, add soil or remove excess. Then it is necessary to pour sand or screenings on the surface - a layer 10 cm thick will be enough, it should not be made thicker. If it is not necessary for water to accumulate on the floor of the gazebo, then it is recommended to make a slight slope of 1-2 degrees.

When laying tile materials, you need to tap each element using a rubber mallet. Having finished laying the tiles, it is necessary to pour fine-grained sand on the surface - the layer should be thin. Then you should carry out the distribution of sand along the seams using a broom. After removing the remaining sand from the surface, you need to moisten it with liquid. For this, it is better to use a spray - the water jet should not be powerful.

Roof

Almost any material can be used as a roof: slate, polycarbonate and other covering products. Then it is recommended to place the roofing sheet on the frame and secure it using self-tapping screws. Previously, you need to cut it, focusing on the size of the slope.

Finishing

The structure can remain completely open. Some people prefer to install small walls on the sides of the gazebo - this design will be more beautiful. You can decorate the gazebo with a wooden or welded lattice, add unusual forged elements. A simpler option is to use moisture resistant plywood.

You can also put benches and a table in the gazebo. To make it more comfortable, some even conduct electricity into such structures.

Care

It is not enough just to carry out the installation work with high quality. If it is necessary for the structure of the profile pipe to last as long as possible, you need to carefully and regularly take care of the gazebo. To avoid corrosion, the surfaces should be protected with an anti-corrosive primer and a protective paint should be applied. High-quality coloring compositions provide reliable protection against the negative effects of liquids.

It is recommended to renew the layer of protective paint and varnish material every few years. Precipitation should not accumulate on the roof of the structure: this should be monitored. You will not have to thoroughly wash the gazebo or carry out any other special treatments - it is quite enough to water the structure with a hose from time to time to get rid of accumulated dirt.

The structure will turn out to be strong and durable if you devote enough time to the installation of the gazebo and do everything as carefully as possible. With due diligence, the results will not disappoint.

Design options

- The design can be completely open, but this option is only suitable for use in the summer season. Such gazebos can be called classic. The design is "enlivened" by beautiful small walls.

Rather thin pipes can be used to create a gazebo.

- Many people prefer polycarbonate sheathing.

- A brazier can be installed in the gazebo - this is ideal for a summer cottage construction.

For information on how to make a gazebo from a profile pipe, see the next video.

The comment was sent successfully.