Sliding gates with a wicket: advantages and disadvantages

Sliding gates have become increasingly popular in recent years. A convenient design with a built-in electric drive makes it possible to control the opening process without leaving the car. We will tell you about the advantages and disadvantages of such gates in the article.

Advantages and disadvantages

Today you can buy all kinds of metal gates, fireproof, sliding, sliding, from corrugated board or euroshtaketnik. The sliding gates have many advantages:

- the movement of the canvas occurs along the fence;

- the gate moves easily, without a hitch;

- the possibility of equipping with an electric drive or manual opening (no need to make any special efforts).

If necessary a wicket can be built into the sliding gate. If you plan to make such a model yourself, then before starting work, you should design a drawing on which you decide in which direction the gate will move. At the same stage, it is decided what kind of cladding material will be used. The gate itself is also being designed.

Then the sequence of all stages of work is determined. This is the only way to achieve the required reliability, durability and safety of the structure.

Sliding products with a wicket have several disadvantages:

- They are more expensive than their swing counterparts.

- To install them, you need to make a foundation.

- To create a product with a wicket door, you need more fittings, material and time.

- They take up a lot of space.

Still, it's worth noting that they have more advantages than disadvantages.

How to do it yourself?

Foundation construction

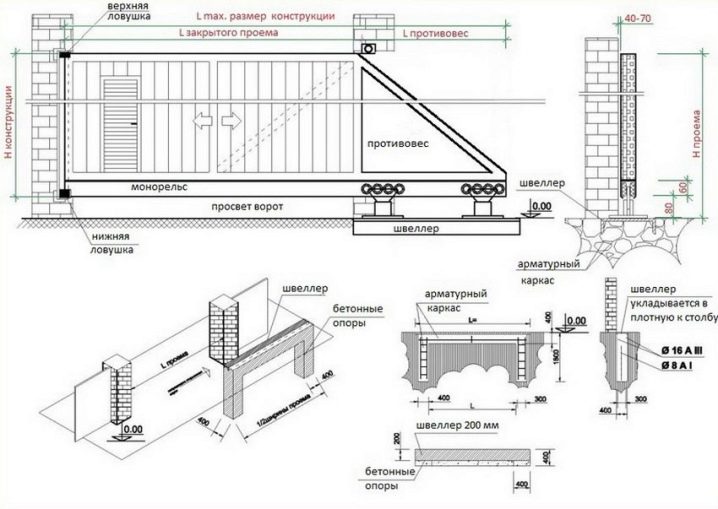

The hardest and most responsible job is laying the foundation. Any construction begins with it. The foundation should be located inside the suburban area, in the side where the gate will drive off. For greater strength of the foundation blocks, before the start of concreting, a reinforced structure is created and the total length of the foundation is calculated.

Before starting work on the foundation, you need to remember the following rules:

- Its length should be equal to half the width of the race.

- The width of the foundation block is made at least half a meter.

- The pouring depth can be up to 1.5 m, depending on climatic conditions.

These parameters are important in the construction of the foundation, because frost and spring heaving of the earth can distort the entire structure of the gate. This will disrupt their performance.

The standard drive width is 4 m, it is suitable for any type of transport. Based on this length, the length of the foundation blocks is calculated, it will be equal to 2 meters. A site is being prepared for arrival. For this, the top layer of soil is removed to a depth of 20-30 cm and covered with gravel or sand. Next, you can put asphalt.

Assembling the embedded structure

The embedded structure is a support for elements such as consoles and an automatic gate drive. First, the frame is welded. To do this, you will need two vertical corners, reinforcement rods, a beam with a large section. The length of the beam is 2 m, it is used as an embedded element and is installed on top of the frame.

The welded structure must be of sufficient strength. It should be placed in a trench and concreted. The support beam does not need to be completely covered with concrete.

In the process of concreting, you need to use the building level in order to achieve a horizontal position of the frame.Then the gate will slide without distortion.

The level of the landing area and the frame must be the same.

Sections

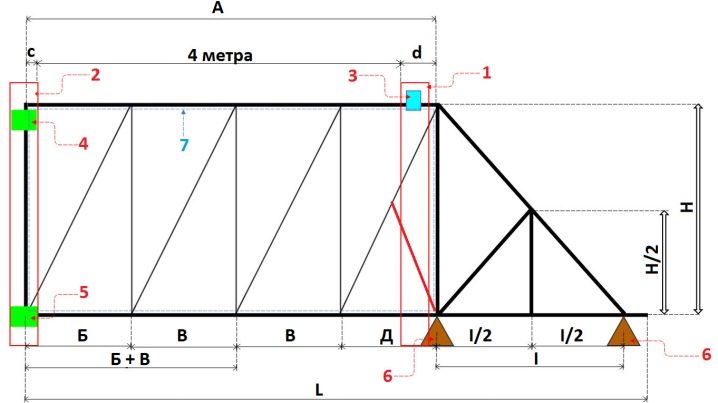

Sliding gates are constructed according to the same principle as other types. The differences are in the number of sections: for ordinary gates you need two of them, and for sliding gates only one. The rigidity and strength of this structure is due to special ribs.

If, when designing a gate, a standard drive-in width of 4 m is taken, then another 2 meters is added to the length of the section. Thus, it turns out that the length of the lower side of the section will be 6 meters, and the upper side is 4 meters. The general view of the structure will look like two connected geometric shapes - a triangle with a right angle, and a rectangle.

To strengthen the strength of the section, profile pipes are used. They are installed in order to avoid distortions. This is the most vulnerable spot of the moving canvas. They are attached in the form of a cross or mesh.

The installation of a wicket inside the gate deserves a separate consideration. It is better to choose more expensive hinges for wickets. It is not worth saving on them. These are some of the most mobile structural elements. They must be of high quality and reliable in use.

It is not recommended to build a built-in wicket in sliding gates. But if there are no other options, then it should be designed at the stage of frame design. It is better to place it, stepping back one meter from the edge of the section, and not in the center. The standard width of the wicket is 1 m, its frame is welded into the common frame separately.

On the sliding gates the gate should open into the yard, then it will not interfere with the sliding of the canvas. Installing a built-in wicket is cheaper than installing it separately. But this cheapness has its drawbacks. The design loses in rigidity, and it becomes necessary to step over the threshold.

The gate is mounted on ready-made runners. They can be purchased or made to order. The finished structure of the gate and wicket is carefully treated to remove rust. The cleaned surface is primed and then painted.

Without this work, rust even under the paint will continue to corrode the iron. Over time, small bubbles will begin to form and the paint will fall off.

Installation

The lifespan of movable elements on sliding gates will depend on their correct installation. It is recommended to make the gate opening process automatic. To make it smooth and unhurried, gearboxes are purchased. They reduce engine speed.

Specialist shops can offer this automatic movement. Don't try to invent it yourself... The factory kit contains all the necessary elements. There are also installation instructions, so you can do the whole assembly yourself.

To make the control remote, special elements are used, making them hidden. This allows you to activate the power from the remote control button.

For moving elements, a frame is also needed. For this, a frame is specially cooked to the length of the gate. Its installation is carried out on dowels and anchor bolts. It is attached from the inside of the fence, where the gate is open. You can strengthen the structure with a crossbar. It is placed diagonally and should not interfere with opening.

After installing all the moving parts, the motor and control parts are installed. The electric drive needs electricity, for this they carry out the wiring. Insulation with a corrugated hose will make it resistant to damage and safe to use.

Between the rolling track and the ground leave a gap of more than 5 cm, so that fallen snow and swollen earth do not interfere with sliding. Following the recommendations of experts, a speed bump is set up in front of the gate. He will protect the canvas, preventing the car from accidentally rolling.

The wicket built into the sliding gates has another significant disadvantage.The wicket can remain open during the movement of the curtain, which may lead to its damage. For this, a special controller is ordered, which will not allow the drive mechanism to work if the gate is open.

Sheathing

Gate cladding is the very last stage of work. An appropriate material must be attached to the fabricated and painted frame with a wicket. Usually, a material similar to the finish of the fence is used. The financial capabilities of the owner play a decisive role in this case.

The main rule for choosing door trim is lightness of the material. Otherwise, the drive mechanism should be purchased more powerful. The best option is a polycarbonate sheet. Also suitable are aluminum and profile sheets, plastic lining and sandwich panels.

Profile sheets are the classic cladding for all types of doors. To ensure resistance to dents, it is best to choose a material that is at least 3 mm thick. The assortment of profile sheets on the wound is quite large. There are special types of sheets for gates, wickets and fences. They have a high quality stainless steel finish.

If you want to create a beautiful and unique pattern or even a photo on the gate, manufacturers are ready to provide the required type of profiled sheets. Due to the quality of their material, the drawing will be of high quality and resistant to UV radiation and hail. The paneling is attached to the gate with bolts. The color of the cap must match the color of the selected metal profiled sheet. Self-tapping screws are also used for fastening.

Do-it-yourself sliding gates are a completely feasible idea. If you take a responsible attitude to the choice of materials and preparatory work, then the ready-made sliding gates will be durable and comfortable to use.

You will learn how to mount a sliding gate with a wicket in the next video.

The comment was sent successfully.