How to choose a sliding gate automation?

Sliding gates are becoming more and more in demand every year, they clearly outperform swing structures. This can be explained by several factors, and the most important of them are the simplicity of design, versatility, and low price.

Peculiarities

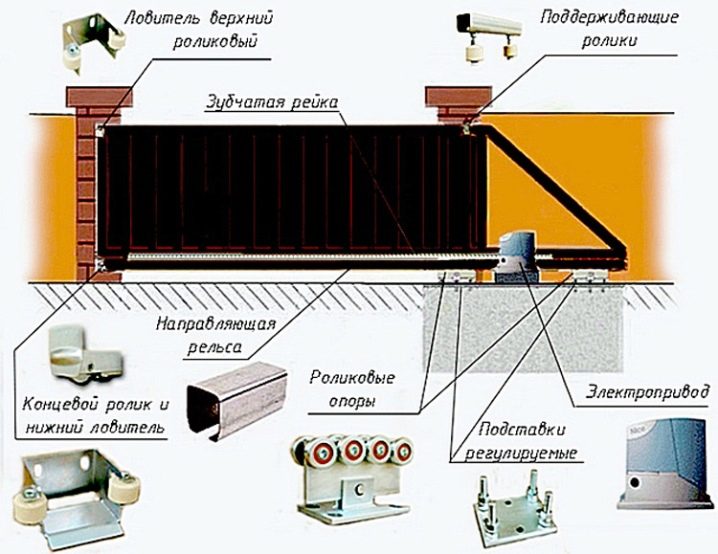

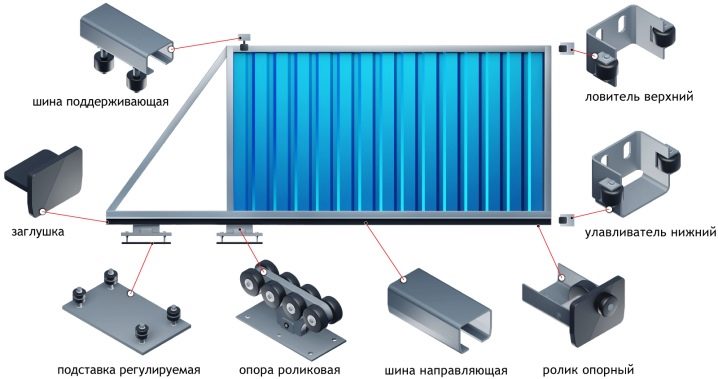

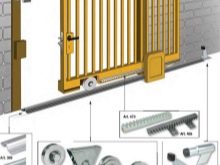

Conventional sliding gates have:

- Guide rail made with the letter "P";

- Supports in the form of rollers (2 pcs.)

- Removable roller at the very end;

- Catcher at the bottom;

- Catcher at the top;

- Locking device at the top.

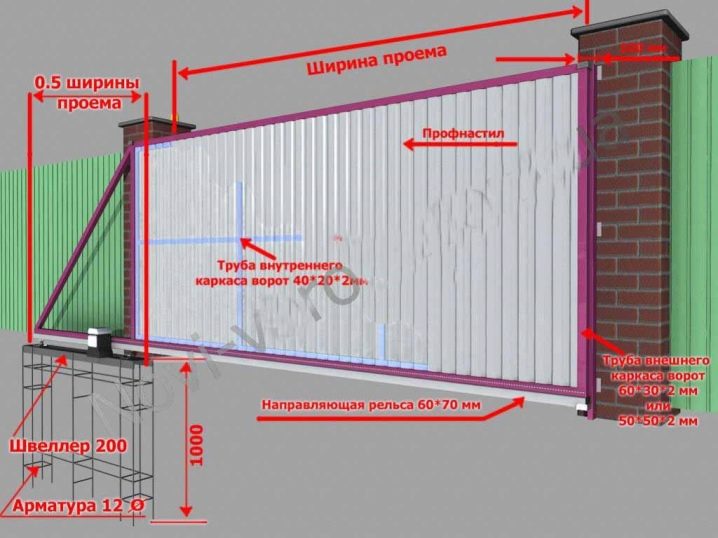

Before installation, the foundation is cast, roller supports are mounted on it, a rail is mounted at the bottom of the frame - a guide, which in shape resembles the letter "P". The rollers allow the gate to move smoothly on a horizontal plane.

No additional floor space is required for sliding gates. In winter, there is no need to remove snow in front of the gate to make room for opening. But you should carefully monitor the roller bearings: lubricate them with oil, remove dirt in a timely manner.

The advantages of sliding gates:

- Strength;

- Simplicity of construction;

- Aesthetic appeal;

- Space saving;

- Reliability and simplicity in operation;

- Quiet work;

- Automation is connected and can be operated by DPU;

- Simple maintenance.

The gates consist of one or two leaves and are found everywhere in such objects as:

- Trading bases;

- Warehouses;

- Supermarkets;

- Automotive enterprises;

- Military towns and many other administrative and commercial facilities.

Often, sliding gates can be found on the territory of private households.

If a failure occurs in the electrical networks, the current disappears, the gate can be opened and closed manually. They can be easily mounted on almost any object, at the same time, finishing with a variety of materials is possible:

- Metallic profile;

- Wood;

- Sandwich panels.

Another important aspect: sliding gates, due to their design, do not have special guides at the top, which are often an obstacle to the passage of large vehicles.

The peculiarity of installing such gates is that a certain space is required in order for the sash to pass unhindered. There are cases when the gate is mounted from the outside. The disadvantage of this design is the complexity of installing the automation control unit.

The quality of fittings is important in the operation of sliding gates, Very good fittings are produced in Italy and Austria, for example, companies such as:

- Welser Profile;

- Rolling Center Basic;

- Came;

- Nice;

- Faac.

Rating of the most famous companies in the field of sliding gates production:

- Came;

- Faac;

- Nice;

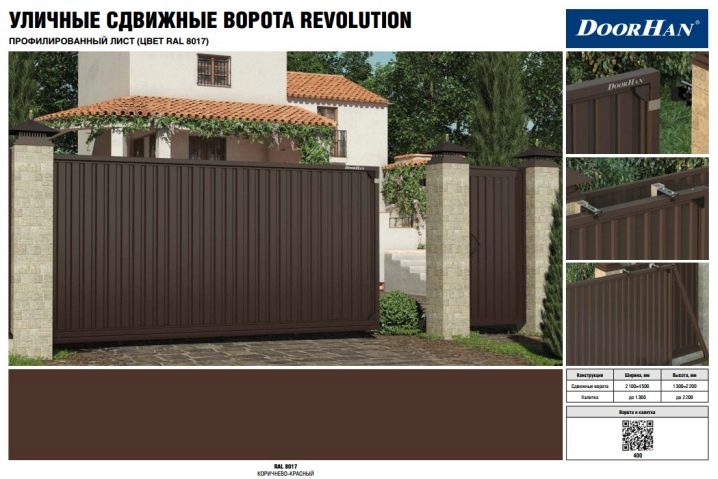

- Doorhan.

The last trade mark is Russian. In terms of reliability, this company occupies high positions in the ratings.

Views

The use of sliding gates is economically profitable, since they are relatively inexpensive and have a number of undeniable advantages. Sliding gates are:

- Console;

- Rail;

- Suspended

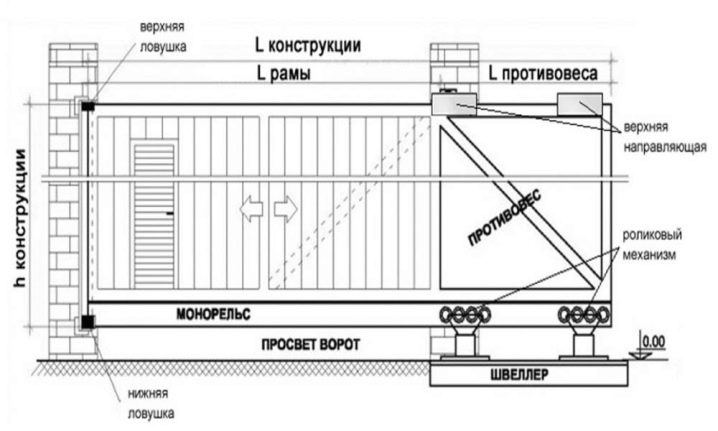

Sliding gates are difficult to install and expensive to maintain. Their main advantage is high reliability. The door leaf is attached to a beam, channel or rail using rollers. The rail is mounted on the foundation and is the main guide. Hanging gates are most often found on the territory of industrial facilities. This design is solid, but it is not in such demand as in the old days.

There are several reasons for this:

- Suspended road gates in operation;

- The design provides for the presence of a beam above the opening, which often interferes with the passage of large-tonnage vehicles.

Advantages of rail gates:

- The design allows you to overlap large areas;

- Good resistance to wind loads.

Suspended sliding gates have guides that are installed at the top of the opening, the doors themselves are suspended on roller mechanisms. Most often, such designs can be found in warehouses, motor depots, factories. The rails are put in the opening here, and the wheels "run" along the canvas.

Such structures are expensive, so the demand for them is moderate.

Advantages:

- Stability and good wind resistance;

- Reliability - can withstand a lot of weight;

- Large openings can be made.

Disadvantages:

- High price;

- There are height restrictions;

- Bulky.

Console-type sliding gates are the most practical type of such devices. A beam is installed on the foundation, the door leaf is attached to it with the help of roller trolleys.

Advantages:

- A small distance from the surface (up to 95 mm) makes it possible to function smoothly at any time of the year;

- The gate format can be very different;

- Installation and operation are inexpensive;

- It is not required to prepare the opening;

- Functional drive;

- Work without noise;

- There is an automatic, operating mode, as well as manual.

Among the shortcomings, we can mention:

- There is some difficulty in installation compared to other types of gates;

- A smooth surface is required;

- On the retractable side, nothing should impede movement.

Sealed bearings are used in the rollers, they do not clog up with dirt and do not need special care. Roller devices are reliably isolated from the harmful effects of the environment. Typically a roller carriage has 8 bearings, which are securely fixed.

The average number of cycles exceeds 40 thousand. It is required to lubricate the gate when a creak appears in the area of the retractable mechanism.

Sheathing of sliding gates, for example, overhead gates, can be:

- Decking;

- Wooden clapboard;

- Polycarbonate.

Selection Tips

To use an automatic gate in a private house, it will be enough to buy a gate where the engine is powered by a conventional 220-volt electrical network. If the weight of the gate is more than 300 kilograms, and the width is more than 4 meters, then the engine should be bought one that can "pull" the weight up to one ton.

Gate automation completely depends on the intensity of work, this topic is especially relevant for enterprises where there is a lot of traffic

It is not recommended to buy automation in which the nodes are made of plastic, this is wasted money. It is better to overpay than to acquire a thing that will become unusable in a short time.

Often unscrupulous manufacturers stamp plastic additives on metal mechanisms, so it is better to buy products from well-known brands. In recent years, nodes have appeared made of an aluminum alloy of silumin, which is also not a reliable material and is very fragile.

The electric drive unit ensures the operation of all automation. The drives can be either horizontal or vertical. If the layout of the block is horizontal, then you can connect automation to it. If we talk about the shortcomings, an intensive accumulation of dust is possible on such a box, which can negatively affect the normal operation of the system.

The radio receiver in such sliding gates is also sometimes "naughty" and refuses to function normally.

To automatically stop the gate, there are limit switches, which are made in the form of brackets or magnets. The latter are more expensive than "mechanics", as they are more reliable in the cold season. If the frosts are strong, then the oil in the "mechanics" can freeze and the operation of the mechanism will malfunction.

Italians first came up with the idea of opening and closing gates from the control panel.In this country, most of the companies that specialize in automatic electric drives.

Mounting

Sliding gates compare favorably with sliding gates and are differentiated according to the following indicators:

- The weight. A very important factor on which the operation of the entire structure depends.

- Material. It can be both corrugated board and wood, metal sheets, etc.

- Fittings. Reliable fittings are a guarantee that the gate will last a long time.

- Engine power. This indicator directly depends on the weight of the structure. Some people buy engines with pampas gears. Doing this is strongly discouraged.

Engines are usually installed on similar structures with the following power:

- 200-250 W - will work with a structure weighing up to 400 kilograms;

- Up to 400 watts - such an engine will be able to "pull" a structure weighing 0.5 tons;

- about 600 W - "cope" with massive gates weighing one ton.

If there is a 30% marker on the equipment, it means that the operating and idle times of the drive are distributed in proportions of 30% and 70%. It is not particularly difficult to count further: a gate with an opening of 5 meters operates at a speed of 10 meters per minute. The complete opening / closing cycle is about three minutes. The gate will be able to perform up to ten cycles per hour.

If such a design is present in a suburban private household, then this is quite appropriate, but for a car company where cars leave and arrive every five minutes, such gates are not suitable.

Possible intensity options:

- 30% - for private households;

- 50% - for a small car depot, where about two dozen cars are parked;

- 70% - for enterprises with 25 cars.

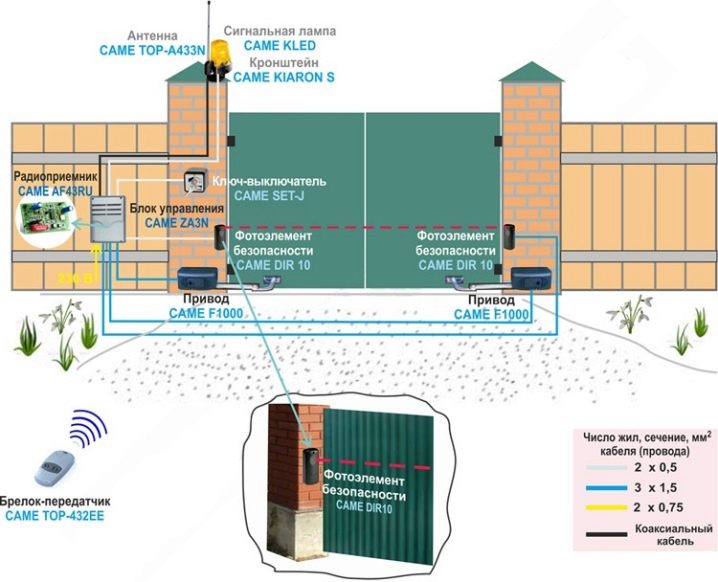

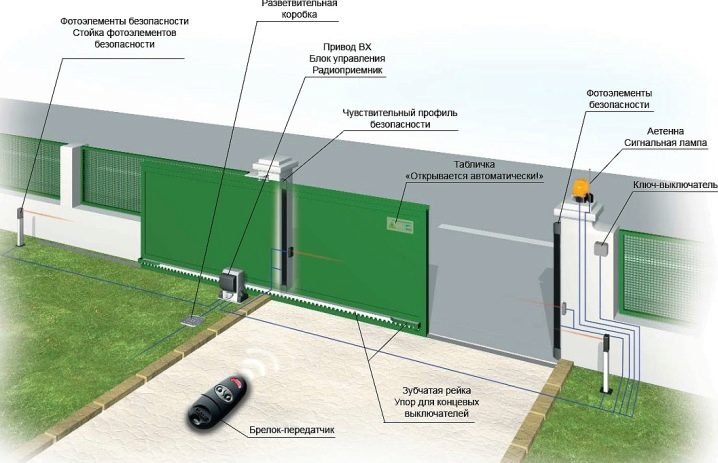

Even the best equipment can fail. In order for the sliding gates to work in automatic mode, it is necessary:

- A good drive with a cable, its tension must be at the proper level;

- Control block;

- Limit position switches;

- Rack;

- High-speed unit responsible for automatic operation;

- Photocells of safety (scanners for admission);

- Signal lamp.

Installation of sliding gates is a responsible and troublesome business. The entire scope of work is divided into several stages:

- Installation of the base;

- Installation of cables;

- Installation of gates and posts;

- Installation of an automatic drive;

- Door leaf finishing (forging, galvanizing, wood);

- Circuit connection, setup.

Installation work is always carried out in several stages:

- First of all, you need to make a foundation;

- Sliding gates are made;

- Then the installation of the gate is done;

- Automation is being mounted;

- The strength of the foundation is important. Automatic gates imply the presence of a base for the drive, it must be above the channel.

A very important stage is the installation of the pillars. For these purposes, you can use a concrete pillar or a metal pipe with a diameter of 10-15 cm.

A hole is dug one meter deep, and a trench is also dug under the foundation 40 centimeters deep. It is necessary to install a metal channel measuring 15 x 20 cm, its length should be equal to the length of the foundation. Metal "legs" with a diameter of 12 mm are welded to the channel. The channel is laid in a trench, a metal pipe is installed and fixed; the pits are filled with concrete.

After that, a temporary pause is taken for a period of two to three weeks.

The limit switch of the sliding gate drive on the toothed rack is attached at the bottom of the sash to the pipe of the gate frame itself. The rail can be made of polymer or metal. More reliable is the metal construction.

With an electric drive, it becomes possible to automate the process of opening and closing the gate. This is done in a domestic environment using a special control panel.

Every technique requires preventive maintenance. If, for example, cantilever doors are installed, then at least once a month in the cold season it makes sense to check the rollers, clean them and lubricate them with oil.

Also a weak point is the electric drive, which is exposed to intense loads and temperature changes.

The sliding gate operator is the main component in the entire structure. Almost everything depends on the success of his work. To settle on one thing, it is worth analyzing the various models. You should also be aware of the choice of these things so that they serve faithfully for a long time.

It makes sense to pay special attention to the gate bus, which can be:

- Miniature;

- Average;

- Big.

The drive should be selected appropriately. Each manufacturer produces all of the above formats. When buying, you should only understand what dimensions of the gate you need.

For cantilever sliding gates, a counterweight is required, which makes it possible to bring the leaf into balance. Often the size of the counterweight takes up almost half of the web area.

Reducing the size of the counterweight increases the load and the friction increases. A similar phenomenon will provoke premature wear of parts. This topic is especially relevant in the cold season, when there is high humidity, night and day temperature drops, due to bad weather, the risk of mechanical microparticles entering the working mechanism increases.

The drive is subject to increased loads under these circumstances and may fail. That is why it is recommended to choose it with a large power reserve.

A lot depends on good fittings. For example, if the rollers do not work well, then this will generate unnecessary loads, and the risk of damage to the mechanism will increase. The sliding gate operator should work effortlessly... It is recommended to keep this in mind when installing the gate. If the installation of the gate is not done according to the rules, the automation will soon break down.

Manufacturers

Gates Alutech positioned as universal devices. Can be completed with both drives AN-Motors, for which the price is quite affordable, and more expensive devices from Nice and Marantec. You can choose the option you want without much difficulty. Alutech equipment is represented in Russia by more than one dealer, each of them can offer tangible discounts.

Came Is one of the most famous brands. The Came operator is especially popular for sliding gates. The Came BX-78 model collects good reviews, it works flawlessly with gates that weigh up to 780 kg. It has the following functions:

- Self-unlocking;

- Motion tracking sensor;

- Obstacle detection sensor;

- Control block.

The model is also attractive because it is easy to install with your own hands.

The equipment also has functions:

- Advanced control system;

- Isolation of the engine and control unit;

- The decoder is compatible with different transmitters and can also memorize codes.

There is a special system that protects the engine from unnecessary loads. The cost is approximately 15 thousand rubles. The Bx-243 model works best with gates weighing up to three hundred kilograms. This format is optimal for private households.

The advantages of the model include:

- Universal control board;

- LED indicator that makes it possible to diagnose the state of the system;

- Ease of installation;

- The gearbox is easily unlocked with a key.

In the event of a power outage, a mode is triggered in which a spare battery will be used.

Doorhan products are one of the best on the market. Its advantages:

- Reliability;

- Many modifications;

- Simplicity.

The system is suitable for the widespread door format weighing up to 800 kilograms "Doorhan Sliding - 800 KIT"... It functions flawlessly even at -20 degrees. The motor and gearbox are located in a single unit, which makes it possible for the equipment to function more efficiently. All units are designed to work in the harsh winter conditions of Russia. A similar model costs about 15 thousand rubles.

Good line of automatic drives Faac, they are well made and functional. The devices from this manufacturer have special microprocessor units, double-disc clutches in an oil tank - all this allows the devices to function efficiently and without failures.

Faac 741KIT is designed for gates weighing less than 950 kilograms. Normal operation can occur even at -30 degrees. The company has come up with a special grease that is not afraid of cold weather and reliably protects the gearbox from seizing. The package also includes:

- Control panel drive;

- Lamp;

- Security nodes;

- Receiver.

The control unit is enclosed in a heavy-duty plastic case, which protects it from mechanical damage.

Sliding gates, which are manufactured by Hormann, are ideal for such objects:

- Warehouses;

- Workshop;

- Repair bases;

- Objects under construction.

They are produced in a variety of formats. These are very reliable products that can serve for a very long time without preventive maintenance.

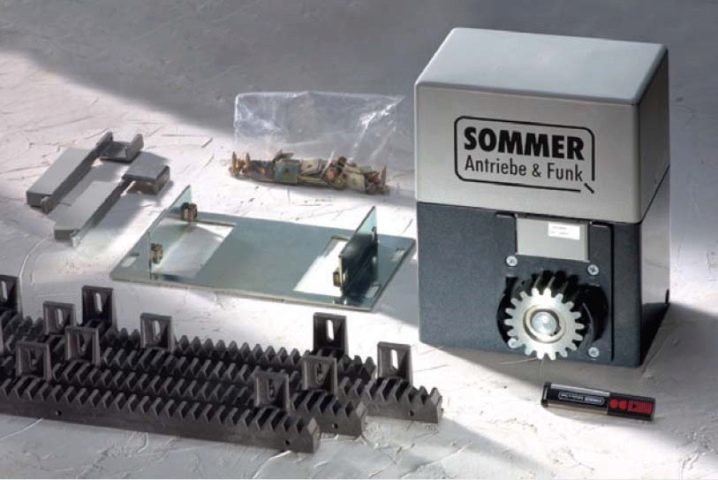

Production of the company Sommer (Germany) recognized all over the world. Its products are of high quality and reliability. The "highlight" of Sommer - actuators equipped with automation that allows you to detect obstacles.

Italian manufacturers are also well represented in the market. The Came firm (Italy) is widely known. She owns a lot of know-how in developments in the field of automation. Manufacturers from China are more and more actively opposing European brands, every year making products better in quality, but with noticeably lower prices.

For example, the Chinese company Gant is steadily increasing its market share in both Russia and other countries. The equipment is inexpensive, simple and reliable, which makes it possible to operate the equipment in any weather conditions.

Reviews

Buyers mainly discuss the reliability of various equipment. The advantage of sliding gates, in their opinion, over swing gates is undeniable.

How to choose the right set of equipment - this question worries many motorists. Someone claims that it is better to buy Italian models. In terms of reliability and quality of performance, they seem to be out of competition. Some people praise the German equipment, they say, in terms of electrics, they are very reliable. Often the question arises about the merits of sliding and sliding gates. Still, preference is given to sliding gates.

For information on how to choose an automation for sliding gates, see below.

The comment was sent successfully.