Features of wood axes

One of the most ancient tools used in everyday life is the ax. Among the huge variety of modern models made of metal, wooden structures are also popular. We will talk about them in this article.

Characteristic

The shape and size of a wooden ax can be the same as that of a metal one. However, this is where their similarities end. The wooden ax has a number of advantages, among which are the following:

- a light weight;

- safety in use;

- ease of manufacture.

Among the disadvantages are the following:

- small impact force;

- lack of a sharp cutting blade;

- fast wear of the working part.

Due to these features, the scope of a completely wooden ax is very limited. Such a product is more often used when cutting thin twigs, for example, when making a fire. The ax is convenient to take with you on a hike. It is important to note that in order to maintain a working tool, it is required to provide constant care and proper storage.

It is recommended that such a product be used only where possible. In this case, the product will serve for a very long time.

Material selection

The choice of the type of wood should be approached with special responsibility. The strength properties of the product, its reliability, and service life depend on this. Preference should be given to hardwoods.

The following types of wood are most often used to make an ax:

Jatoba

The material has high impact strength, hardness, toughness. Jatoba is easy to process. It has excellent aesthetic properties and is ideal for making an ax.

Ash

The material is characterized by high strength, hardness, long service life, and aesthetics. By its properties, wood is similar to oak. However, unlike the latter, ash has elasticity.

Oak

The wood is characterized by high strength, good aesthetics, and long service life. It is easy to process. However, oak has a high hardness, which can adversely affect the skin of the hands during prolonged use.

Birch

Such material is used less often for the manufacture of an ax. Birch quickly absorbs moisture, which is a favorable environment for insects to appear. Such wood requires careful preparation and constant care.

How to make it yourself?

A wooden ax can be easily made with your own hands. All work is conventionally divided into 3 stages:

Preparatory

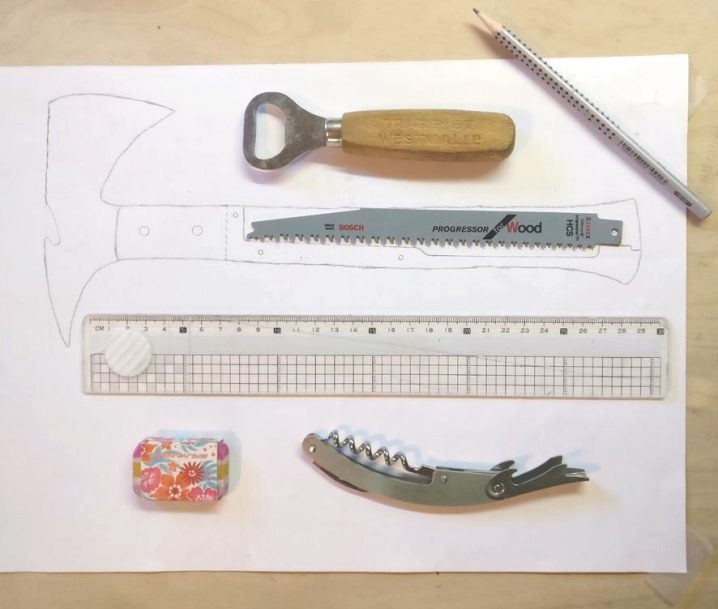

At this stage, a template is being prepared. The workpiece material is dried and leveled. Working tools are being prepared. When creating a model of a future product, it is important to correctly determine its size. It is necessary to take into account the height, mass of a person. The length of the handle should be equal to the distance from the wrist to the shoulder joint. The hand should completely cover the handle of the ax.

Basic

The product is cut out according to the template. Work can be done with a jigsaw or a knife. The design can be one-piece, or it can consist of a head and a handle that must be connected. If the wooden products are solid, then after cutting, they begin to sharpen the working part. Sharpening is done at an angle of 25-30 degrees away from you. Then fine-tuning is done.

If the structure consists of two parts, then before sharpening it is necessary to connect the handle to the working part.

Final

The surface is being leveled. You can use sandpaper for this. Further, the product is processed with oil and painted.

About. how to make a wooden ax, see the video below.

The comment was sent successfully.