All about fire axes

The fire ax was designed for a specific profession. There are several characteristics that distinguish it from other products of this type, in particular - the shape with a classically made blade on one side and a pointed end on the other. These axes are of different types.

Features and scope

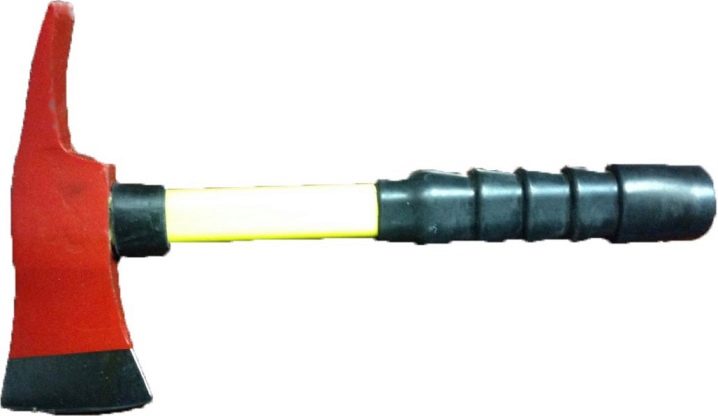

A typical fire ax is always long-handled. The metal element is attached to the handle especially firmly - so that it does not bounce off during a large swing. The product is painted in a bright color, which makes it easy to see the ax in poor visibility conditions.

The dual design of the product allows firefighters to use one tool instead of two. With this unit, you can cut down doors, quickly pull out trim and door jams, and break plasterboard surfaces and paneled ceiling tiles. Some models are designed to cut electrical wires, although additional options can significantly affect the cost of the tool. Fire axes can also be used for quick access to vehicles and other tasks. The design is thought out in such a way as to create the possibility of safe, quick and efficient entry into the premises.

Some workers use a tool to demolish walls. The curved axle design makes it suitable for a wide range of applications. This shape is necessary to reduce weight, but at the same time maintain strength and correctly distribute the stress and force applied by the user. The belt ax hangs on a holster, a similar assault tool is firmly attached to the lower back.

Like any ax, this tool can be dangerous if used incorrectly. Firefighters usually receive training in the use of the tool before using it. First, you need to make sure that the structure is in good condition, inspect how firmly the metal part is fixed to the handle. In addition, the blade of the assault ax must remain sharp.

Principle of operation

An ax is an example of a double ramp wedge. This shape during operation allows you to reduce the effort required to complete the task. Its handle acts as a lever allowing the user to increase the force at the cutting edge.

Most of the axes of the handle of the fire ax are symmetrical about the blade, but there are models where the boundaries are displaced, which makes it possible not to subject the joints to a large load. The American instrument and the models made in our country are almost identical. The main work surface is made of high-strength steel, and the handle can be wood, fiberglass or plastic.

Manufacturing

Special requirements are imposed on a tool of this type, since the material must withstand not only heavy loads, but also be fire resistant. The working surface should not change its characteristics under the influence of a constant temperature drop. If we talk about strength, then such a tool is capable of piercing steel, the thickness of which is 1 mm. The head is made not just from hardened steel, but from a material with the addition of molybdenum and manganese - it is they who provide the necessary strength. To protect the device from corrosion, a special compound is applied on top.

The metal element (if it is not a one-piece structure) is attached to the handle using epoxy glue. The product is dried in the oven for 24 hours at a temperature of 30 degrees. For better contact with the hand, a rubberized pad is installed, which allows you to firmly hold the tool even when wearing gloves.

If it is a professionally made ax, then it must have a quality certificate. At a certain stage of production, the product is tested for resistance to stress and strength. According to the regulations, the service life of a fire ax is 18 months. If chips appear during operation, the tool becomes unusable, since such defects indicate aging of the metal, which in this case is unacceptable.

Specifications

In accordance with the standards, the length of the fire ax cannot exceed 0.36 m, while the weight should not be more than 1.2 kg, the wedge-shaped blade - 0.2 m, and the height - 0.07 m. Even the sharpening angle has its own requirements, it should be 30 degrees. In the central part, the permissible butt thickness is 0.03 m.

The fabric is made by forging - alloy steel is used for this. Both the pick and the blade must be in the same plane, there is no margin of error. Heat treatment of the pointed part is possible only in the factory, while the finished product must be free of irregularities, and the working surface must be perfectly flat.

Views

Of the available options, the fire ax can be:

- waist;

- assault;

- sledgehammer.

CCI tool (that is, a belt ax) is an important part of a firefighter's outfit, as it allows you to quickly respond to a difficult situation and open access to an enclosed space. It fits into a cover and is attached to a waist belt in such a way as not to hinder a person's movements. This is an all-metal tool, so there is no risk that it may break during operation. There is a rubberized tab on the edge of the handle. On one side of the working surface there is a thorn, on the other - a chopping part.

A flat sharp surface is used for cutting wires, wooden barriers, while the handle is a dielectric, so the firefighter does not have to fear for his own safety when the tool comes into contact with an electric current. The part, made in the form of a pickaxe, is an indispensable assistant if you need to pick a lock or stay on an inclined surface.

TPSh-SP (or assault fire ax for the shield) more massive, it weighs much more and has impressive dimensions. From the name it is easy to guess for what purposes such equipment is used. The length of the handle can vary from 60 to 90 centimeters. It is such a handle that allows you to swing well and make every effort to hit. Unlike the previous model, the handle of this ax is made of fiberglass, hence the durability and strength of the structure. If we talk about the shape of the working surface, then on one side there is a cutting element, and on the other - a pickaxe.

Sledgehammer ax differs from other options only in the shape of the base, since it does not have a spike, but there is a flat surface that makes it possible to break dense walls.

Models

Of the models of fire axes on the market, it is worth highlighting the product "Voevoda". The manufacturer used ideal geometry in the design of his tool, respectively, during use, it was possible to reduce recoil, but increase the effort.

The handle is a steel tube with an oval cross-section. The transparent dielectric polymer is located over the entire surface, so the user is not afraid of electric shock up to 1000 V. The grip is complemented by a pad.

The firefighter has a low cost ax FIT 46112, its weight is 1.25 kg, the handle is made of wood, and there is no pickaxe in the design of the working surface.This is one of the simplest options that you can use when you need to enter a room.

Other modern options are distinguished belt CCI-1... The handle is made of nylon with fiberglass inside. There is a pickaxe on one side and a flat part on the other. The product is attached to the belt using a special holster.

Austrian model Leonhard Mueller has a low weight (700 grams), but costs an order of magnitude higher than the above models. The inflated cost is justified by a solid construction, the use of quality materials. The total length of the product is 380 mm.

For more information on fire axes, see the video below.

The comment was sent successfully.