Features of forged axes

Forged axes are a popular tool and are widely used in many areas of human endeavor. Their high demand is due to the special strength of the material obtained by means of the oldest metalworking method - forging.

Manufacturing process

Forging is considered one of the traditional methods of making axes and is in many ways superior to more modern technologies. Its main feature is a change in the structure and density of the metal, as well as the elimination of cracks and air cavities in it. Forging axes is a handicraft performed by blacksmiths. Metal processing is carried out by means of manual or electric hammers by shaping hot workpieces into desired shapes.

In this case, the shock load acts on the entire mass of the metal, leaving no residual stress and cavities in it. As a result, the entire thickness of the material receives a directional structure, while becoming very strong and resistant to any stress. Forging blanks for axes is performed several times, due to which slags are displaced from the pores, and the existing cavities are filled with metal.

The next step in forging an ax is to shape the blank into the desired shape. The process consists of shaping the blade and bending the eyelet with its subsequent welding by means of forge welding. Moreover, the area of the eyelet is made less hard in comparison with the blade of an ax, as a result of which the metal is more viscous, which allows nails to be driven in with the back of the tool. And the metalworking is completed by the fine finishing of the ax, which is carried out by the method of sharpening and grinding.

The final stage in the manufacture of the tool is the creation of a hatchet - a wooden handle of an ax. For this, hardwood is used: beech, birch, ash or acacia. The shape of the shaft depends entirely on the purpose of the instrument, and its length is usually calculated individually. So, the optimal size of the handle is the distance between the shoulder and the wrist: it is this length that the hatchet is considered safer to work with.

Advantages and disadvantages

The popularity of hand-made forged axes is explained by a number of their advantages over tools, made in other ways.

- The quality of forged models is much superior to the quality of stamped and cast ones, which is due to the technology of multiple forging and metal hardening.

- The hatchet always matches the purpose of the ax and is often custom made.

- In addition, only high-quality wood is used for the manufacture of the handle, which excludes its splitting under the influence of heavy loads.

- And also, many professionals note the excellent attachment of the ax to the shaft, which allows you not to worry about it falling off the ax during the felling process.

- Another significant advantage of forged models is their durability. Such a tool can serve for more than a dozen years and is often inherited from grandfather to grandson.

However, like any other tool, forged axes still have drawbacks. First of all, they include a high cost, which is explained by manual work, which has always been expensive.In addition, blacksmiths sharpen each specific model exclusively for a specific type of work, and in order to use it for other technical tasks, the blade will need to be resharpened. The next significant disadvantage is the risk of purchasing a product of low quality, during the manufacture of which the metal was not finished or overheated.

To protect yourself from purchasing such a product, you should use the services of experienced professional blacksmiths who value their reputation and are personally responsible for each product they make. Another significant drawback of a forged ax is the need for proper sharpening. A forged blade cannot be sharpened using conventional metal grinding: in this case, a fine-grained grinding wheel is required along the forged edge. Even more difficult to sharpen are patterned blades that should only be handled by professionals.

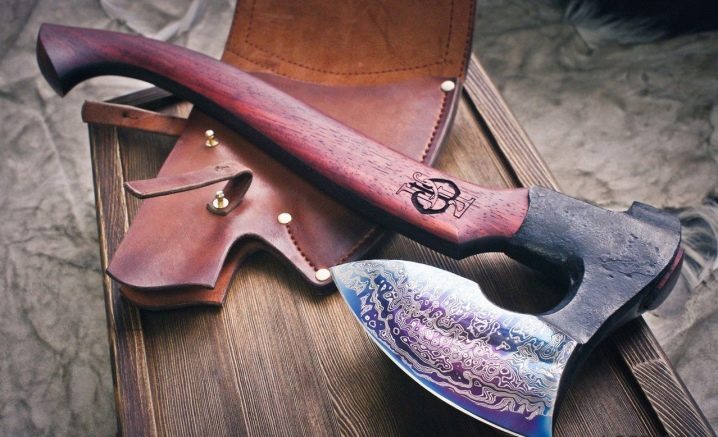

Design

The device of a forged ax has remained unchanged for more than one hundred years and includes a number of elements.

- Blade is the main working part of the ax and undergoes a separate hardening. With proper use, a well-sharpened blade practically does not dull. Usually, forged axes use the technology of central sharpening, when only the middle of the blade is to be sharpened. At the same time, the edges are deliberately made somewhat duller, which allows the ax to more efficiently enter into the depth of the wood.

- Striker or blade, is a flattened surface ending in a blade and is the main part of the ax. The optimal blade weight is 800-1000 g. Such models are considered universal and suitable for most types of activities.

- Hatchet is a wooden handle and is responsible for the ease of use of the tool. According to the configuration of the profile, it should resemble an egg, since the handles of this particular shape fit most comfortably in the hand. The length of the handle varies depending on the purpose of the model. For example, for cutting down lying trees, it must be at least 70 cm.

This size significantly reduces the risk of injury when, in the event of a miss, the blade goes into the ground, rather than sinking into the leg. In addition, the long handle does not imply bends and end nubs. Due to the sufficient length, the handle holds so well in the hands and does not slip out. But for carpentry and joinery models, on the contrary, only short curved handles are used. They greatly simplify the work, not allowing the tool to slip out of your hands.

In addition to hardwoods such as apple, pear, birch and elm, aspen is a good material for the shaft. Aspen handles significantly lighten the weight of the product, the main thing is to choose the right wood and dry it well. It is strongly not recommended to use oak with mahogany for handles: southern species behave unstably in a harsh climate and often burst in the cold.

- Eye is a special hole into which the handle is inserted. The attachment of the ax to the hatchet can be carried out with the help of five wedges or by the reverse thrust method. In the first case, the wedges are coated with epoxy resins, driven into the eyelet close to the hatchet and additionally poured with resin from above. This method is the simplest, but over time there is a risk of losing the ax when swinging.

The second method is more reliable, and under no circumstances will the ax fly off the handle. To do this, a little metal is removed from the eyelet, giving it the shape of a cone. Then they take a birch blank, which has a thickening at the end, and put an ax on it using the reverse thrust method so that at least 5 cm of the hatchet comes out of the eye from above. Then wedges are twisted into the eyelet from below and coated with resin.An ax fixed to the handle in this way will stand there for a very long time, and can fly off only when the birch begins to rot from old age.

- Butt - the blunt part of the ax opposite to the blade, often used for hammering in nails. Usually it becomes more viscous and does not allow metal splitting even when driving in dowels.

- Beard - a figured blade protrusion, which is not present on all forged models. Basically, it is equipped with hunting (taiga) models used for butchering animal carcasses, and sometimes tourist axes.

Views

In total, there are five varieties of forged axes, each of which has its own structure and specialization.

- Carpentry models belong to the lightest category of axes and weigh between 600 and 900 grams. Products are usually equipped with a straight cutting edge and are sharpened at an angle of 20 degrees. The tool is intended for use in a summer cottage or in a workshop, being the least expensive type.

- Carpentry axes are more massive than carpentry and weigh 1-1.5 kg. A distinctive feature of such models is a rounded cutting edge, which is necessary for working with a log. By the way, old huts, built without a single nail, were cut using just such models. The blades of carpentry axes are sharpened at an angle of 30 degrees, which prevents them from getting stuck in the wood and makes it easy to get out even from deep and narrow crevices.

- Taiga or hunting ax quite rarely goes on sale, mainly made in blacksmiths' workshops on an individual order. The weight of a hunting model is usually 600-800 g, which makes it easy to carry it through the forest and perform many operations with it. The taiga differs from other types of tools, for example, from a carpenter's ax, by a rounded, not very long blade. Thanks to the narrow blade, the ax is able to penetrate deep into the wood to a great depth and quickly chop trees.

So, with the same effort, a carpenter's ax with its straight and flat blade will enter the tree by 4 cm, while the depth of entry for a hunting model will be 8 centimeters. This allows, under the same conditions and physical costs, to cut down a tree 2 times faster. In addition, the hunting models are equipped with a goatee, which protects the handle from fractures during strong blows carried out across the wood fibers. Taiga models also differ in that the front end of the blade is wider than the rear, which allows the ax to be used as a cleaver.

- Cleaver intended for splitting firewood, there are two types: "iron" and "sledgehammer-cleaver". The first has an unpretentious design, presented in the form of a wedge-shaped ax and a straight handle. The second is distinguished by a more curved hatchet and narrow blade. For a cleaver, the most important properties are the weight of the head and the toughness of the metal. He does not need a special sharpness of the blade, which is why he does not need regular sharpening. The butt of the cleaver is adapted for hitting a sledgehammer, and therefore rather mild steel is taken for its manufacture. The weight of the ax varies from 800 to 1200 g, which is quite enough to split a log.

- Solid Forged Ax of the Butcher intended for cutting carcasses of different sizes, as well as for cutting bones and frozen meat. The short handle, usually no more than 50 cm, has a curved shape for a comfortable and safe grip. The length of the blade varies depending on the model and often reaches 30 cm. The weight of the products also varies, and for some handmade tools it can reach up to 4.6 kg. The hardness of the metal at the meat axes corresponds to the RK 57-58HRC marking.

How to distinguish from cast?

Distinguishing real forged steel from a cast product is fairly straightforward.To do this, it is enough to knock on the ax with a thin metal object, for example, a long nail: a real forged product will ring for a long time, and the sound will resemble the ringing of a bronze bell. The sound from the impact of the nail on the molded product will be dull and short. Another difference between forging and casting is the presence of a stamp. Almost all forged models are branded, while there is no stamp on cast products. In addition, cast axes often show a characteristic casting seam.

Subtleties of choice

The purchase of a forged ax must have a compelling justification. This is due to the fact that the cost of such models is several times higher than the price of stamped and cast axes, therefore, for rare use, it is better to purchase a simple model. The only exception is the cleaver, which must always be forged. When choosing an ax, you need to pay attention to the presence of a stigma and grade of steel, as well as inspect the edge of the blade: it should be perfectly flat, without burrs and chips. The best option is to order an ax from a blacksmith, but if this is not possible, then as an alternative you can buy a Ural ax produced by the Izhstal - TNP company. The company produces fairly high-quality products, and the stable demand for it confirms this.

For information on how to distinguish a forged ax from a cast one, see the next video.

The comment was sent successfully.