Which polycarbonate to choose for a greenhouse?

Given the ever-growing popularity of polycarbonate, many are interested in what type of this material to choose for building a greenhouse? First of all, it should be noted that we are talking about such characteristics as strength, durability, and most importantly, about effective heat conservation and light transmission.

Currently, manufacturers represent a fairly wide range of their products in the corresponding market segment. In such a variety of types and parameters, not all buyers manage to navigate and make the best choice, the results of which would satisfy all the requirements.

Choosing by density

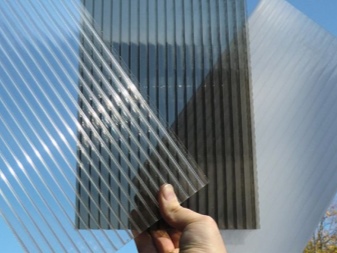

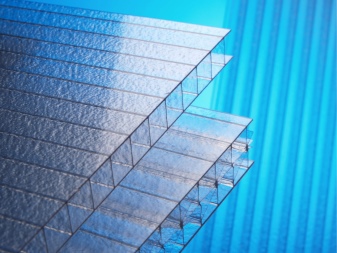

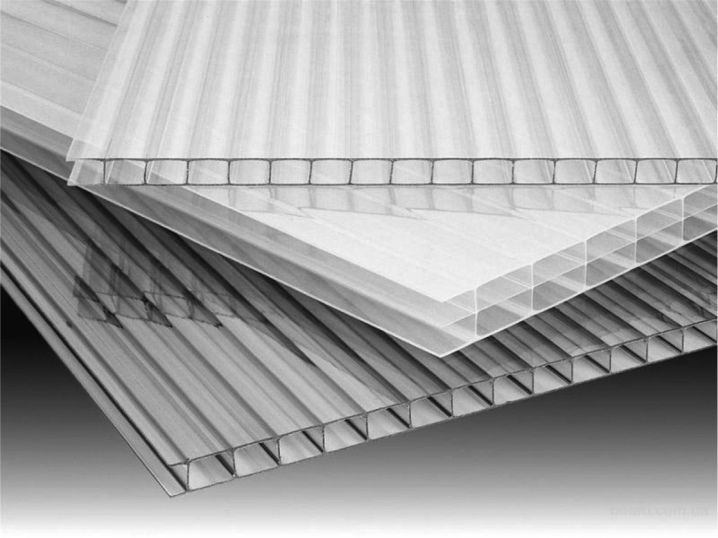

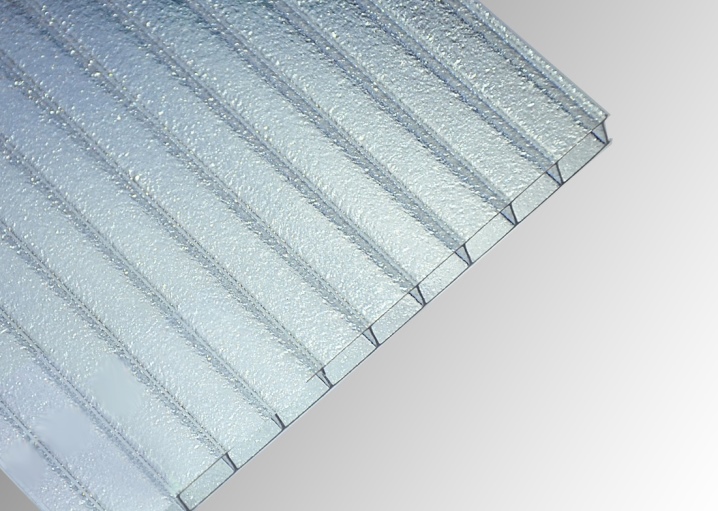

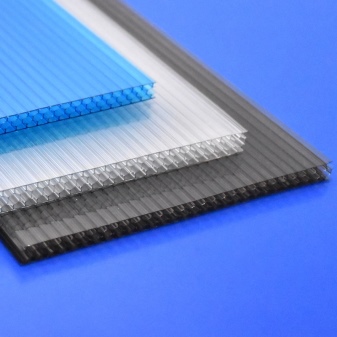

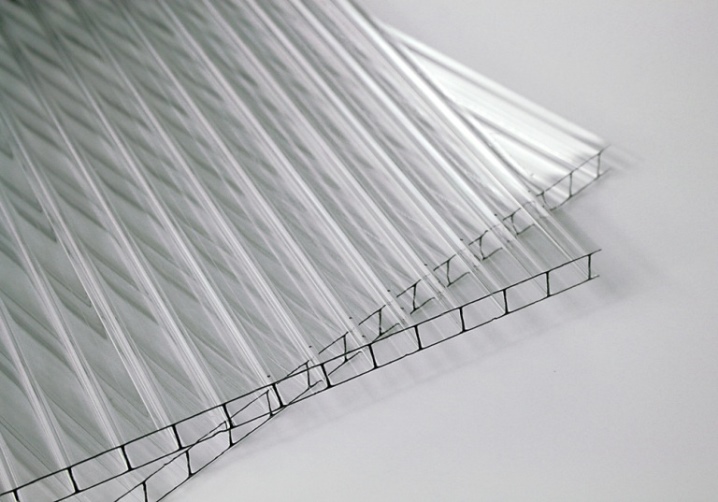

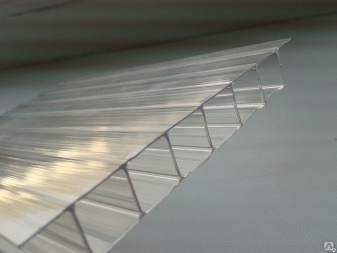

This modern material is produced in the form of sheets with certain dimensions and characteristics. In order to choose the right polycarbonate for different greenhouse models, a whole list of factors must be taken into account. In accordance with current statistics, as well as numerous reviews of experienced summer residents, the most suitable option is the cellular type. At the same time, attention is focused on the fact that such polycarbonate retains heat better.

Such performance indicators are due precisely to the cellular structure of the material.

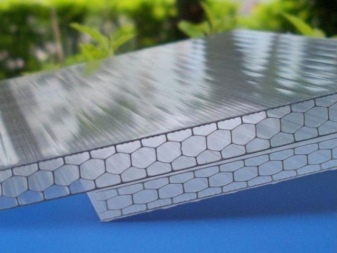

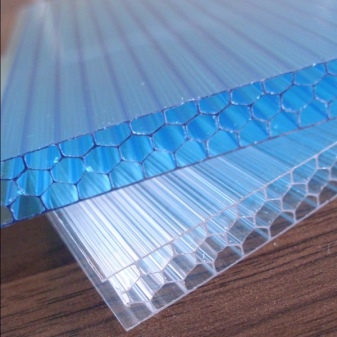

An equally important point is the stiffness of the sheets, on which the resistance of the entire structure to various influences will directly depend. We are talking, in particular, about winds, as well as precipitation in the form of snow in winter. The correct selection of its elements will help to ensure sufficient rigidity of the entire structure. If we mean a polycarbonate sheet, then the emphasis should be on the structure of the cells (honeycomb), as well as on the density.

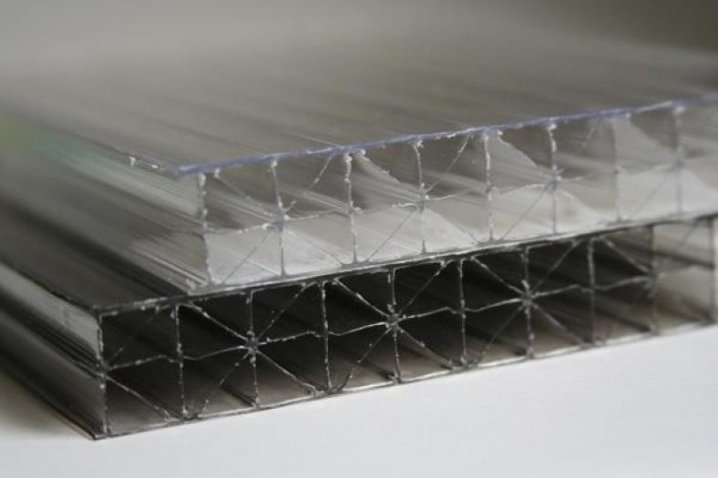

Analyzing the key properties of the reinforced sheet, it is worth noting that such an indicator as density is determined not only by the configuration of the honeycomb. An equally important factor is the features of the partitions. To date, models are produced with cells in the form of:

- squares;

- rectangles;

- hexagons.

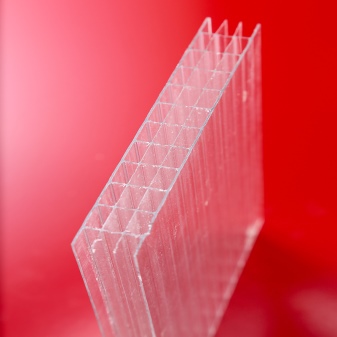

So, according to experienced gardeners and experts, when creating winter greenhouses, the strength of the base material deserves special attention. In situations like this, it is best to use a high quality PC that has hexagonal honeycombs. At the same time, it is worth considering that such sheets are characterized by the lowest level of light transmission. This means that if you cover the structure with a similar polycarbonate, then you will not have to count on a good harvest without additional high-quality lighting.

Models with rectangular cells today are the lightest and most affordable. Such material transmits light better than all other modifications. If you take such sheets during the construction of a greenhouse, then you should not rely on the high strength of the structure, since their density is quite low.

The golden mean will be square honeycombs. Such a PC has good light transmittance against a background of sufficient strength. Based on such a combination of operational properties, this can be called the best option for greenhouse structures intended for use in the country in the spring and summer.

As already noted, the density index of the described material is closely related to the structure of the cells. A similar dependence can be displayed as follows:

- rectangular partitions - 0.52-06 g / cu. cm;

- square cells - up to 77 g / cu. cm;

- hexagon-shaped cells - 82 g / cu. cm (the highest to date).

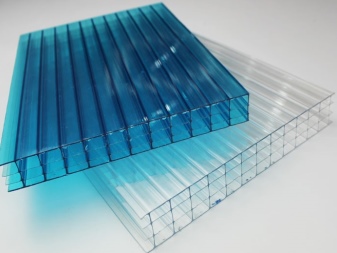

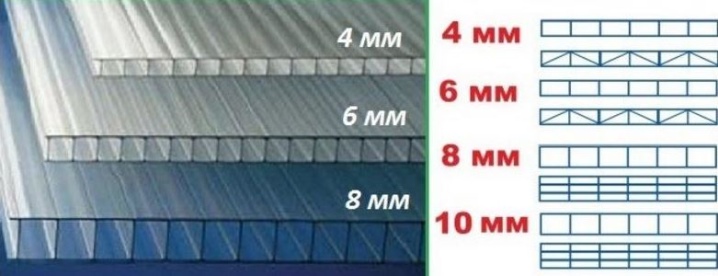

How thick can it be?

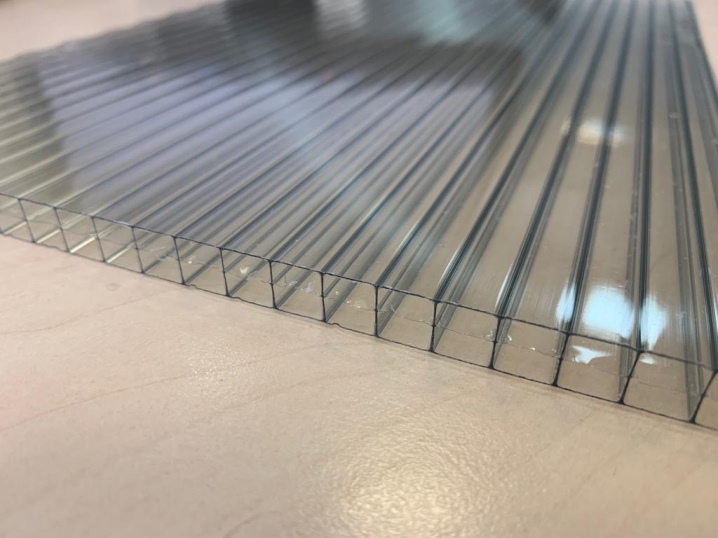

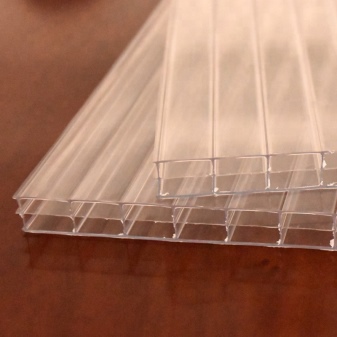

In addition to density, the list of key criteria for selecting the optimal type of material for the construction of greenhouse structures also includes the thickness of the profile sheets. At the same time, it is strongly recommended not to choose the extremes in one direction or the other. That is, in each specific case, we are talking about the so-called golden mean. If you give preference to sheets that are too thin or thick, the structural strength or light transmission will suffer.

In accordance with the recommendations of specialists and the reviews of experienced summer residents, the optimal indicator varies in the range from 4 to 8 mm. At the same time, when making a choice in favor of the upper limit, it should be borne in mind that we are talking about the most dense sheets, which will transmit light worse. They are relevant mainly for the construction of winter structures, that is, when maximum strength is put at the forefront.

When choosing a PC in terms of thickness, a whole list of determining factors should be taken into account.

- Climatic features of the region, such as the nature and amount of precipitation. This is mainly about snow and means the potential load on the future structure.

- The prevailing direction of the wind and the maximum force of its gusts.

- The material from which the greenhouse frame will be made. Naturally, the most durable are metal structures. The timber frame has a lower load-bearing capacity.

- Distance between the flooring battens and the frame itself. The closer to each other the elements of the future structure are located, the higher its strength will be. In such situations, you can choose polycarbonate with a lower thickness.

- Seasonality of operation of the structure. So, if planting will be carried out in spring and summer, then there is no need to use thick PC sheets. If we are talking about year-round operation of a greenhouse for growing crops on an industrial scale, then it is worth stopping at a thicker polycarbonate.

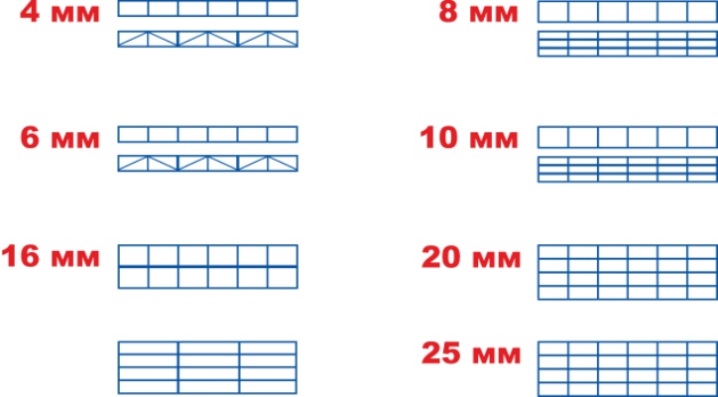

It turns out that the thickness of the material when choosing is determined primarily by the features of the operating conditions. Based on the scope of application, polycarbonate sheets can be distributed as follows:

- 4 mm - greenhouses small in surface area;

- 6 mm - greenhouses with a small area;

- 8 mm - large greenhouses;

- 10 mm - glazing of large greenhouse structures;

- 16 mm - due to the increased density and rigidity, the material is used in the construction of entire greenhouse complexes;

- 20 mm - construction of winter gardens and greenhouses.

According to the advice of experienced craftsmen and users, for a medium-sized greenhouse, the best solution would be to choose polycarbonate with a thickness of 6 mm. This approach to the choice of materials will be most relevant for regions where moderate snow activity prevails.

Which is better: with or without UV protection?

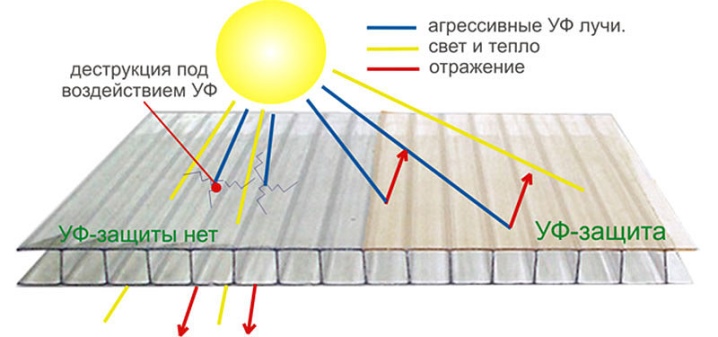

The essence of the whole structure is that polycarbonate will be constantly exposed to ultraviolet rays that destroy it. Based on this, it is recommended to consider options for sheets that have additional protection. In a similar way, it is possible to ensure the safety of both the material itself and the plants for which hard radiation is harmful.

Modern technology for the production of polycarbonate provides for the application of a thin, but at the same time the most reliable film on the surface of sheets. It does not flake off during operation and prolongs the service life of the material while maintaining its strength. It is important to remember that when installing a PC with a similar film, the protective layer is placed outside.

Choosing budget options with a minimum thickness of protection or without it at all, you should not count on a long service life.As practice shows, after 2-3 years it will be necessary to change the cladding of the greenhouse structure. It should be noted that data on the availability of protection are indicated in the documents. As a rule, visually checking the presence or absence of a film is not always and not everyone succeeds. At the same time, markings are most often present on the canvas, which allows you to determine how to position the sheet when installing it.

Other selection criteria

Knowing the characteristics of polycarbonate, you can choose the most suitable material in each case. So, when erecting a capital structure for year-round growing of plants in regions with difficult climatic conditions, preference should be given to reinforced PC sheets. However, the selection criteria are not only density, thickness and the presence of UV protection.

Reliability, durability and all other performance indicators of the future greenhouse will largely depend on the quality of the PC. Often, cheap materials are made from recycled materials and with violations of technology. In such cases, the service life will be from 2 to a maximum of 5 years. As practice shows, little-known firms are often unable to offer products of the required quality.

Based on this, experts recommend buying materials from well-known brands for which reputational risks are unacceptable.

When choosing a brand and basic parameters of a PC, first of all, it is necessary to take into account the peculiarities of its potential use. In addition to the characteristics already listed, attention should be paid to:

- the mass of the profile;

- maximum bending radius;

- the color of polycarbonate sheets;

- light transmission capacity of the profile.

In addition, the integrity of the material must be taken into account. Profile sheets should be as flat as possible and not have any damage, deformation and creases.

At the development stage of any project, in order to determine potential loads, including on the frame, as well as during the installation process, the mass of all materials used must be taken into account. A clear advantage of polycarbonate is its minimal weight. That is why it is used in situations where maximum structural lightening is at the forefront at various density indicators. PC sheets are equally suitable for steel, aluminum, wood and plastic greenhouses.

Among other things, the weight of the profile has a direct impact on its service life. In practice, this parameter is most relevant in situations where the choice is made in favor of cellular polycarbonate. We are talking about the effect on the mass of the thickness of the partitions between the cells, which, as a rule, is rather difficult to assess by eye. In such cases, the following ratios of weight per "square" of sheet profile should be used:

- 4 mm - 800 kg;

- 6 mm - 1,300 g;

- 8 mm - 1,500 g;

- 10 mm - 1,700 g;

- 16 mm - 2700 g.

It is important to remember that heavier polycarbonate sheets provide increased protection against all sorts of influences. At the same time, the lightweight material does not have sufficient bearing capacity. At the same time, heavy models are more expensive than light ones with the same dimensions.

The PC profile is capable of bending without preheating, without losing its characteristics, including strength. You can determine the maximum bending radius of the sheet using the formula: R = t * 175 (t is the profile thickness, and R is the desired value).

It turns out that a 10 mm sheet can be bent up to 1.75 meters. Taking into account the design features of the material, this indicator varies in the range from 0.6 to 2.8 m. The bending radius should always be taken into account during installation, since exceeding the value leads to deformation of the profile and even to its destruction.

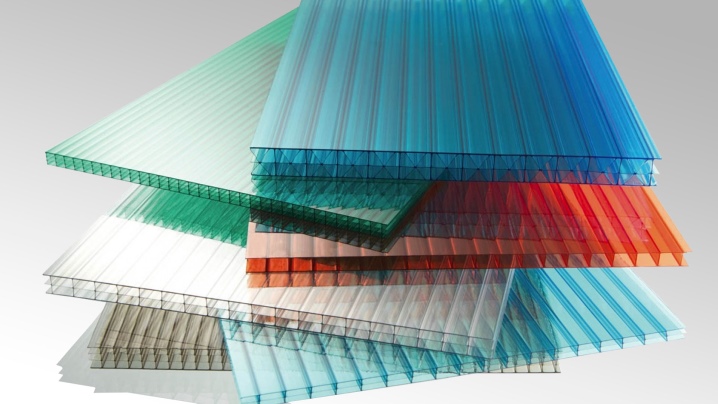

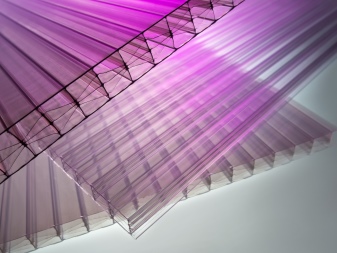

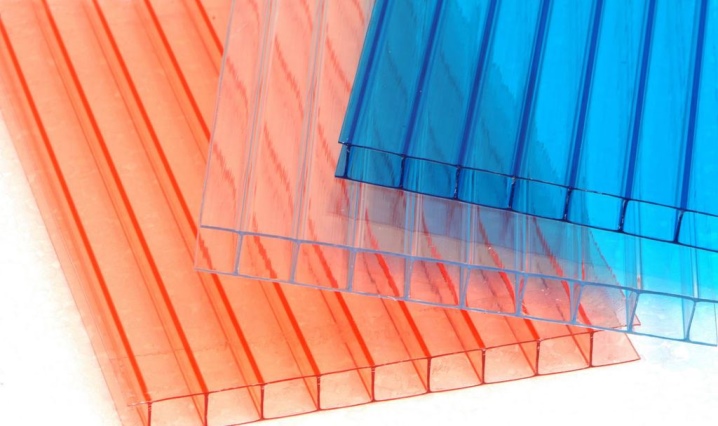

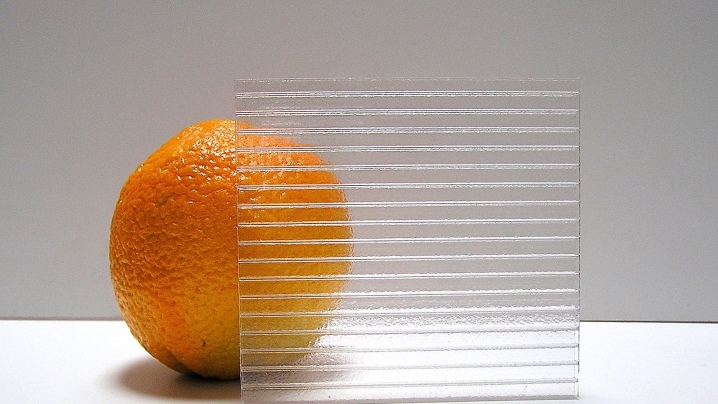

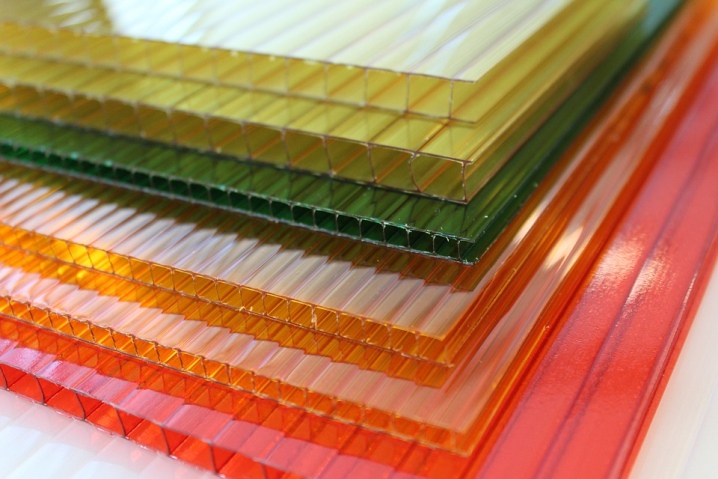

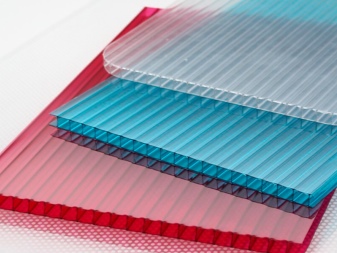

The next important selection criteria are the color of the material and the percentage of light transmission. The latter, due to the unique properties of PC, can reach 92%.In parallel, due to the structure of the plastic itself, an effective diffusion of light rays is ensured. By the way, this is another clear competitive advantage of using polycarbonate. Due to diffused lighting, the plants inside the greenhouse receive maximum solar energy, penetrating from almost all directions.

As you know, the considered sheet profile can be of different shades.

In order to determine with maximum accuracy which color will be optimal in a particular case, it must be borne in mind that the percentage of light transmission directly depends on it. By the way, blue-violet and orange spectra are most favorable for plant growth activation. On the other hand, in a greenhouse structure covered with green polycarbonate, the process of photosynthesis is significantly slowed down.

The types of PCs available today on the market can be classified according to the following indicators of the percentage of light transmission:

- opaque (milky, white, silver, pearl, golden) - from 20 to 30%;

- conditionally transparent (bronze, yellow, orange, red, blue, green and turquoise) - from 35 to 75%;

- transparent, that is, colorless - from 86 to 92%.

Now in specialized stores a fairly wide range of colored polycarbonate is presented. At the same time, you can often find advice to make a choice in favor of orange and red profiles, since these colors are the most favorable for plants. However, it should be borne in mind that the light transmittance of such a material is relatively low. This will be a negative factor for most crops, and you should not count on a solid harvest.

In practice, most summer residents prefer the sheathing of greenhouses with transparent PCs. It, in contrast to matte and color, transmits and dissipates the maximum percentage of sunlight necessary for the growth of crops.

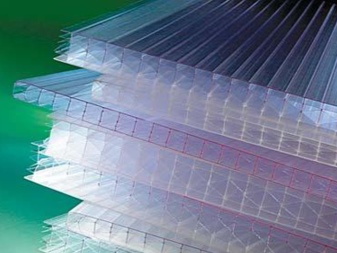

Another important point when choosing a material for greenhouse structures is the answer to the question of which polycarbonate is more suitable: monolithic or cellular. It is worth recalling that it is polycarbonate that is the ideal material in the context of creating and subsequently maintaining the optimal temperature and humidity inside the greenhouse, regardless of its size.

However, it is often necessary to decide which profile to take in terms of structure. The following comparative characteristics will help to understand.

- Cellular polycarbonate is lighter than a monolithic one with an identical profile thickness. It is important to consider this when erecting frameless greenhouse structures, as well as when overlapping large areas.

- The cellular PC is characterized by increased energy efficiency. Due to the presence of an air gap between the sheets, the material retains more heat inside the room.

- A monolithic profile will cost more than a competitor.

- The cellular PC ensures the dispersion of sunlight penetrating into the greenhouse, which is important for the development of plants and increasing yields.

Taking into account all of the above, we can make the obvious conclusion that on all points in the context of the construction of greenhouse structures, the honeycomb option wins.

Review of the best manufacturers

The performance properties of the described sheet profile vary depending on the manufacturer. Many specialized companies represent their products in the corresponding segment of the building and finishing materials market. As a result of this diversity and the corresponding competition, the consumer has the opportunity to purchase ready-made sheets or order a profile of non-standard size for the construction of a greenhouse. Taking into account the popularity of the material, current ratings of companies producing PCs are published on many thematic resources.

On the one hand, you can significantly reduce costs by purchasing inexpensive, but high-quality products. However, practice has proven that the choice in favor of cheap products from the “No name” category often turns out to be a serious mistake. A rational solution is polycarbonate of well-known brands belonging to different price segments.

Budget

Now on the market, a sufficient number of manufacturing companies offer high-quality polycarbonate at the most affordable prices. The list of brands producing budget products includes the following firms.

- Plastilux - a company representing the Celestial Empire on the building materials market. We are talking about a PC manufacturer of the Sunnex brand, which will be the optimal solution for those who are trying to save as much as possible.

- Vizor - a company that previously operated only on the territory of the PRC. Today, production facilities are also located in the Czech Republic.

- Italon Is another Chinese manufacturer offering medium quality polycarbonate at the most affordable price with a 5-year warranty.

- "Polygal" - a Russian-Israeli brand under which a material is produced that belongs to the budget category and differs from many competitors in its comparative durability.

- Carboglass Is a large domestic company that provides a 15-year warranty for its products, which in itself inspires confidence. At the same time, the cost of polycarbonate is more than competitive.

- Safplast Innovative - the next representative of Russia in the building materials market. The company manufactures the Novattro brand PC and gives it a 14-year warranty. It is worth noting that these products will cost a little less than the material of the previous brand.

Premium class

As noted, it is not recommended to save on the quality of the polycarbonate sheet profile. Based on this, many give preference to popular brands that have an appropriate reputation. By the way, one of the important points in this case is the duration of the warranty provided by the manufacturer. Naturally, in such a situation, the longer the better, and ideally the warranty period should be at least 10-15 years. And it will not be superfluous to make sure of the presence and authenticity of the certificates when buying.

And the following representatives can be included in the list of companies offering high-quality products to a potential buyer.

- Bayer Material Science - a concern representing Germany on the world market and specializing in various fields, including the production of high-tech materials. The company produces high-quality polycarbonate under the Makrolon brand.

- Sabic Innovative Plastics Is a Saudi Arabian company that manufactures Lexan PCs. Its motto is the active implementation of advanced technologies and innovative solutions in the field of modern polymers. Today the representative offices of this manufacturer operate in more than 40 countries around the world.

- Samyang Is a South Korean brand that represents a high-quality profile on the building materials market, known to the consumer under the Trirex brand. The popularity of the products of this manufacturer is primarily due to the ratio of its high quality and price.

- Teijin Limited - a corporation from the Land of the Rising Sun, constantly introducing innovations in the production process. The result is the production of high quality polymers.

- Dow chemical Is a United States company that manufactures PCs of the Magnum ABC and Caliber brands. The main characteristics of the products are maximum quality, excellent geometry and durability. However, due to the rather high cost, it is little represented on the market.

Summing up, it should be noted that when choosing polycarbonate for a future greenhouse, it is recommended to consult with specialists. It will also be useful to pay attention to studying the reviews and advice of experienced summer residents.

You can learn about some of the pitfalls when choosing polycarbonate from the following video.

The comment was sent successfully.