Features of manufacturing a greenhouse from a profile pipe

There are many varieties of greenhouses. Some are made of wood, others are made of polycarbonate, and so on. Structures made of metal profiles (pipes) deserve special attention. It is this material that can serve for a long time, withstanding strong destructive effects.

Features and types

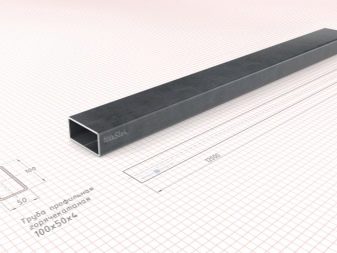

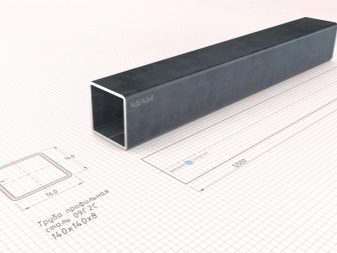

Most of the recommendations that can be found on the Internet are based on standard tubular designs. The profile pipe can be either rectangular or square.

Homemade greenhouses are usually performed in one of three options:

- attached to houses (the roof can be pitched or oval, without pronounced symmetry);

- detached arched buildings;

- greenhouses "house" equipped with a gable roof.

The typical size of the components determines the most common dimensions of buildings: 3, 4, 6 or 12 m in length, from 2 to 6 m in width. The most convenient dimensions for a pair of parallel beds are 3x6 m, for three beds - 3-12x4-6 m.

Advantages and disadvantages

A greenhouse made of a professional pipe has five strengths:

- the design serves for a long time;

- blocks are fixed quite simply;

- assembly is easy and convenient;

- construction can be done in any configuration you like;

- the applied coatings are very diverse.

As for the disadvantages, it is quite difficult to bend the profile. The solution to the problem is as follows: bend one of the pipes filled with sand, trying to give it the most accurate shape, and use it as a template.

The choice of profile and shape of the structure

In the manufacture of a square or rectangular pipe, the following can be used:

- hot deformation;

- cold deformation;

- electric welding;

- electric welding combined with cold deformation.

To make arches, you need a 20x40 profile pipe (10 pieces each), with an approximate length of 580 cm.There are two options: either immediately request cutting to the desired size, or buy conventional models with a size of 6 m.For arched structures, you should take material with a 4x2 section. The lintels are constructed of 2x2 metal (67 cm long).

The official requirements for a shaped pipe are established by GOST 8639-82 and 8645-68. There are options based on various metals, most often builders prefer steel with an external anti-corrosion layer. Optimal reinforcement is achieved with four stiffeners that take up the maximum load.

Galvanized profile pipe must have a special layer both inside and outside. It is not difficult to distinguish high-quality material - it should be quite light. The frame made from it is not difficult to move to another place or transport it by car. Thanks to the solid protective coating, the risk of corrosion is minimized.

If you need a guarantee of increased mechanical stability of the structure, take a profile galvanized pipe with additional reinforcement. Such material easily transfers pressure up to 90 kg per 1 sq. m. According to the provisions of GOST, such structures can serve up to 20 or even up to 30 years. Even if the galvanized layer is bent, dents and other defects will appear on it, but the coating will almost certainly remain intact for a long time.

Welding is used to make a frame from an unprotected pipe. Galvanized elements are connected with bolts, special connecting pieces or corners.It is not very practical to use large diameter metal elements because they are too heavy and uncomfortable.

Project and preparation

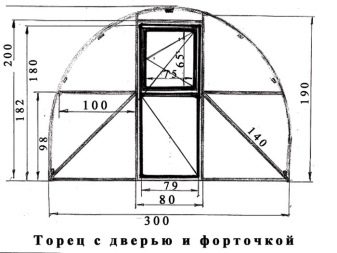

Drawings in most cases are drawn up according to standard sizes - from 300 to 1200 cm. It is recommended to find out this indicator with manufacturers or sellers so as not to overpay for excess material and not to leave scraps.

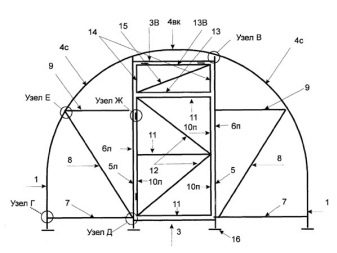

The plans should clearly display:

- base;

- vertically directed racks;

- roof;

- top harness;

- a door;

- windows and vents;

- spacers.

When drawing up a project, you should pay attention to the level of illumination. Any greenhouse must face strictly south. The permissible surface difference is a maximum of 100 mm. In accordance with the scheme, the marking of the building being created is carried out. Stakes and rope are used for this. If you check the marked lines diagonally, you can do everything quite smoothly.

It is not at all necessary to use all profiles with a section of 40 by 20, 20x20 or 40x40 mm. Due to the relatively thick body (from 0.2 cm), such elements are quite strong. Horizontal screeds can be made from a profile with a cross section of 1 to 1.5 mm, because exceptional performance is not required.

When calculating the height of the building, they are guided primarily by the growth of the owner of a summer house or a country house. It is usually assumed that the ceiling should be made 0.3 - 0.4 m higher than those using the greenhouse, because the values can range from 190 to 250 cm.

Sizing has one more subtlety - adaptation to the finishing material. When the frame is covered with a film, it does not really matter, but when using polycarbonate, it is important to ensure that the size of the material is sufficient to cover the entire height without cutting or adding. A typical sheet of cellular polycarbonate is 6 m long. In the case of an arched greenhouse, you need to apply the formula to calculate the circumference. It is worth considering that a height of 2 m is usually excessive, but 190 cm is almost ideal.

When preparing for the construction of a gable prefabricated greenhouse, it is recommended to take into account the properties of the soil. The best results are obtained when installing in dry areas, since with all the protection of the supporting structures, it is better not to subject them to severe tests. Sandy soil is superior to clay soil, since it does not become so swampy.

They try to direct the longest side of the structure to the south, so maximum sunlight will penetrate inside. Placement of the door at the end helps to keep warm inside the greenhouse and to facilitate movement around it.

As the practice of thousands of gardeners shows, the door should be made at least 0.7 - 0.8 m wide. As for the height, it is determined by the overall dimensions of the structure. If it is planned to build a capital greenhouse, a kind of vestibule or corridor is beneficial for two reasons: it forms an additional layer of air (thermal barrier) and can be used as a place for storing inventory. When the doors are opened, this airlock will reduce heat loss.

Foundation construction

Greenhouses made of shaped pipes are lightweight, but this advantage often turns into a serious problem, because it is not difficult for intruders or gusts of wind to break such a structure. The solution is to manufacture a foundation of a strip or pillar type (its choice is determined by the structure of the soil). In any case, before the start of construction, the site is thoroughly cleaned of contamination, the upper layers of the earth are removed. Then markings are made by stuffing wooden stakes around the perimeter of the structure being created, which serve to hold the rope.

Then you can build the foundation itself. If special anti-vandal characteristics are not important, and there is also no threat of strong wind, you can limit yourself to a columnar structure based on asbestos-cement pipes.

The work process includes several stages.

- The ground is drilled with a strictly defined pitch.The diameter of each hole should allow the pipe to go inside freely without fitting.

- Once the supports have been placed in the holes, the outer gaps are filled with any suitable soil that should be compacted.

- The inner part of the pipe is filled with cement, ensuring that there are no cavities.

- A plate of metal or a previously cut piece of reinforcement is introduced from above (this will be the coupling of the foundation and the frame of a homemade greenhouse).

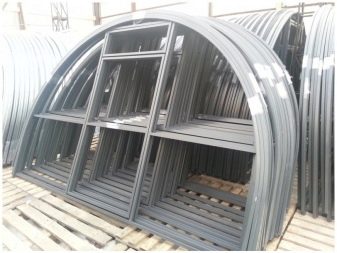

Frame assembly and sheathing

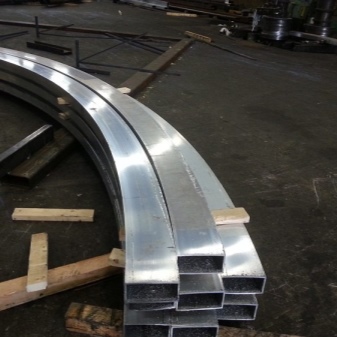

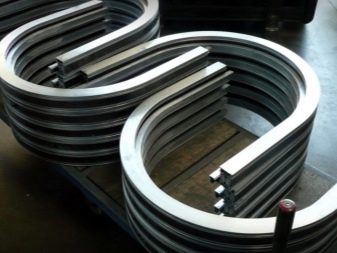

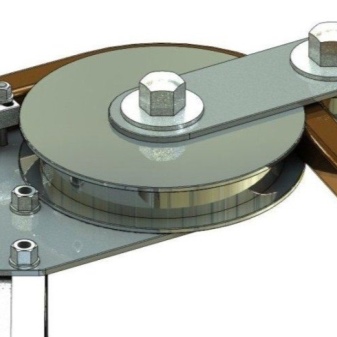

The arc is best created by a pipe bender. Manual work in this case is not only difficult, it also does not allow obtaining the required accuracy. The assembly of the hull begins from the ends of the structure. Pipe sections are usually tied by welding using tees and angles, if you want to achieve the highest strength. But when the task is set to make a collapsible greenhouse with your own hands, you need to use couplings. The final stage is covering the greenhouse body with polycarbonate.

Self-tapping screws with thermal washers are used to fix the sheets.that interfere with the penetration of water into the cells of the substance. The cells themselves should be placed at an angle or vertically, since moisture will begin to stagnate in the horizontal plane and spoil the material.

A greenhouse in the form of a "house" with a full-size gable roof must be equipped with both an entrance door and vents. Specialists make a miniature greenhouse of an arched configuration with only one door, without ventilation ducts.

The advantage of the arch shape is that it is very stable and practical. The aerodynamic quality of the structure allows it to effectively withstand powerful gusts of wind, avoid the accumulation of snow and ice. The problem may only be to correctly bend the profile pipes. In addition to using a pipe bender and contacting professionals, you can also use simpler tools, including a radius template.

It is possible to bend the profile without heating with the addition of a filler, although this is not necessary for elements thinner than 1 cm. If, nevertheless, relatively thick components are used, the addition of sand or rosin greatly facilitates the work, so it becomes easier and faster to bend the thick pipe yourself. Some home craftsmen use large diameter springs that can be inserted into the cavity of the professional pipe. The mechanical properties of such a "helper" provide bending without changing the cross-section of the profiles along the entire length of the pipe.

Another way to shape the workpiece into the desired shape is with a bending plate with holes made in it. The recesses are used to arrange the rods, which will act as a stop. Having placed the pipe between a pair of rods introduced into the plate at the required distance from each other, the profile begins to bend, gradually moving the force from the middle of the piece of metal to its periphery. It is quite possible to do the work in this way, but it will be very difficult, and the result will depend on the efforts made.

Very thick pipes should be bent correctly after preheating. Filling the profile with carefully sifted sand helps to ensure an even fold. Since you will be working with heated metal, protective gloves must be worn. It is also important to take care of the safety of the fire source.

The sequence of actions is as follows:

- create pyramidal wooden plugs (their length is 10 times the width of the sole, at the widest point two pipes should freely enter);

- grooves are made in the plugs designed to bring out hot gases;

- burn the desired section of the profile;

- the filler is freed from very large particles (imprinted on the surface) and from very small ones (they can melt into the metal);

- sand is calcined at a temperature of 150 degrees;

- a sealed plug that does not have recesses is placed on one side of the pipe;

- from the opposite direction, a funnel must be introduced into the profile pipe, with the help of which the calcined sand can be dosed into the cavity;

- the walls are tapping (the sound should be muffled);

- after filling the pipe with sand, use a second plug;

- the bend point is marked with chalk, the segment is firmly fixed in a vice after being applied to the template;

- the welded pipe should be bent with the joints placed on the side (do not bend in the direction of the welded seams);

- warming up along the marking line should be red-hot;

- giving the metal softness, it is bent in one verified movement.

The cooled workpiece, just in case, is checked against the template. If the result is perfect, the plugs are removed and the sand shaken out. If it is necessary to dock metal elements with each other, it is best to weld them.

The gap between the uprights should be 1 m. If polyethylene film is used as a covering material, it is advisable to reduce the distance to 60 cm. Such indicators are determined by the optimal level of load on the pipes. There are situations when the distance has to be increased. Then the structure must be strengthened.

Then a pit 0.8 m deep is dug, which is poured with cement to the longitudinal base (its height is 0.15 m). Further, the bases are welded across the cross-section to the longitudinal elements. Metal corners help to increase the strength and reliability of the greenhouse. A brick is placed under the base, sometimes a shallow groove is formed.

The construction of the frame is preceded by:

- laying out covering material;

- placing arcs on top;

- marking with markers.

When cutting covering materials, a reserve of about 20 mm is left. A frame is mounted on a completely frozen solution, the first arch is welded to all longitudinal bases. When installing it, as when installing the last profile, a plumb line is used to minimize errors. The following parts are connected using jumpers (according to professionals, it is advisable to start by welding the arc to the highest jumper).

Having installed the last arch, the jumpers are mounted at the end. Their profile has a section of 20x20 mm, because the load level is low. Having fixed the covering material, holes for windows and doors are cut out in it. Each joint of this kind is treated with silicone for maximum sealing.

By strictly adhering to these guidelines, you can build a greenhouse that will last over 10 years with almost no maintenance required. And if you make all the calculations so that fewer segments remain, then the work will be relatively cheap.

For information on how to make a greenhouse from a profile pipe, see the next video.

The comment was sent successfully.