Sizes of polycarbonate greenhouses: selection criteria

A greenhouse is a great place to grow greens, tomatoes, cucumbers, strawberries and even flower crops. In spring it helps to get an early harvest, in autumn it helps to preserve summer weather. Both the quantity and quality of the crops grown depend on the size and design.

Features and advantages of the material

Greenhouses can have different coatings - film, glass, polycarbonate, plastic. But greenhouses made of polycarbonate, a monolithic polymer with a different structure, are gaining great popularity.

- Honeycomb - this is a sheet, inside of which cells of different sizes are located, which allow perfectly diffusing light and retaining heat, very durable.

- Monolithic sheet Is a simple flat sheet of polymer, reminiscent of glass, but much lighter, has excellent flexibility and light transmittance.

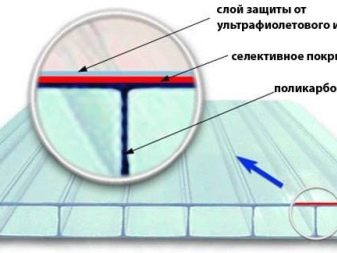

Foxes consist of layers such as:

- solid is a durable sheet that protects from external influences;

- cells that create heat-insulating properties. Thanks to them, the material is light and durable, since the ribs of the honeycomb give rigidity;

- dense solid sheet that is coated with moisture protection.

This material conquers consumers with the following advantages:

- ease;

- impact resistance;

- high transparency;

- high thermal conductivity, and also heat retention;

- transmits UV spectrum;

- flexibility, which allows easy transportation and construction of arched or corner greenhouses;

- ease of care - it can be washed, cleaned from the remnants of leaves, disinfected;

- fire safety - the material does not have flammable properties;

- durability.

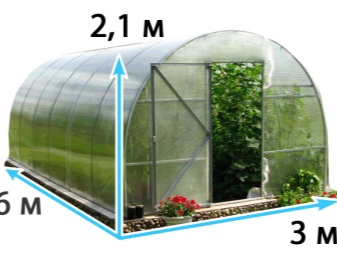

The downside is fast scratching. However, this does not affect the main function, but the appearance suffers. There are different sizes and thicknesses of polycarbonate. However, the optimal thickness for a greenhouse can be called 6–8 mm. 6 x 2.1 m is the standard size. The length may be 12 meters, but such sheets are inconvenient for work, so users prefer six-meter ones.

Sizes: standard and optimal

The size range of greenhouses is varied. They are large, small, under fruits, flowers, berries, vegetables.

The division of sizes is carried out into the following types:

- standard, specified by the manufacturer;

- optimal, suitable for certain areas.

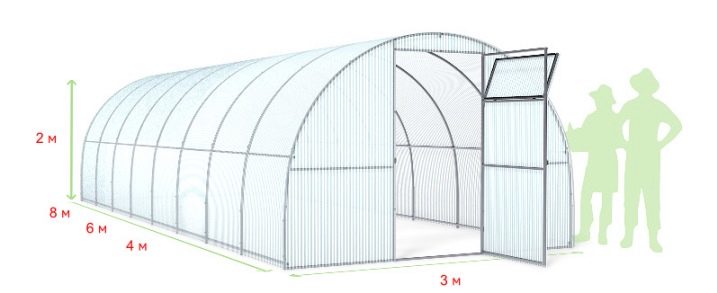

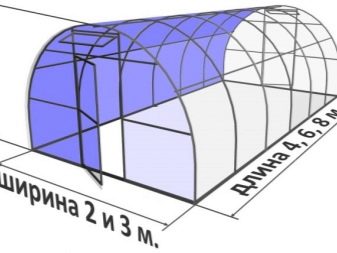

The standard of greenhouses has the following dimensions, depending on the size of the sheet of 6 meters: the height is 1.9 m, and accordingly the radius of the greenhouse, since it has the shape of an arc or an arch. From here it is easy to understand that the width will be two radii - 3.8 m, and the length - 6 m.The optimal size is dictated by a special document - appendix number 85 of the Building Rules and Norms (abbreviated SPiN) dated 02.10.2004, according to which the maximum for width is 260 centimeters, and the height is at least two meters.

The size of the greenhouses depends on the planting crops and the future design is built accordingly.

- Width. When calculating the width, the following necessary parameters should be taken into account. The width of the door is the minimum value corresponding to the shoulder width of an average gardener - 56 cm. The width of the shelves is 97 cm, and the passage between them is at least 60 cm for ease of use. Thus, the minimum width is 2–2.5 m, all other calculations are individual and based on functionality.

- Length. It depends only on the desire of the owner. We take into account that the width of one sheet of polycarbonate is 120 centimeters, and then simple addition and construction of the required length. But be sure to keep in mind that the longer the structure, the harder it is to maintain the optimum temperature. It is especially difficult to do this in winter.

- Height. It depends on the wishes of the user. The design can be low if a person will not enter there, but you can work from above by removing the cover. High if you plan to plant tall crops, and those that need constant care. It is necessary to take into account for this parameter that the plants should have maximum space for favorable development. The standard height is 1.8 m. It is sufficient and optimal. But if the greenhouse is equipped with your own hands, then it is better to choose an integer value - 2 m.

2x3, 2x2 m are small, compact greenhouses that are perfect for small plantings: for seedlings and berries. In the future, they can be used as flower beds or for a small number of fruit crops. However, in a small greenhouse, it often becomes very hot in the summer heat.

In this case, it is necessary to provide access to fresh air to maintain optimal temperature values. If you plan to grow cucumbers, tomatoes or any tall-growing vegetables, a width of 2 m is enough. 2x10, 2x4, 2x8, 2x6 m are the optimal sizes. These options are especially good for long but narrow sections.

If you plan to plant a large number of plants, then you need large sizes - 3 by 4, 3x6, 3 by 8, 2, 4 meters, 3x4. They are suitable for zucchini, eggplants, strawberries, creeping cucumbers. If the owner is a farmer grows crops in large volumes, then it is better to choose large and wide greenhouses - 6x3, 6 by 12 meters. Basically, all sizes depend on the amount of building material and its prices.

Parameters: relationship with constituents

When installing polycarbonate greenhouses, you need to take into account all the nuances and binders. Width and length may not be useful if you do not calculate the structure, foundation, materials and their interactions.

Frame material

The frame can be wood, metal or plastic. Each material has its own pros and cons. The tree is environmentally friendly and inexpensive, however, it is very dependent on temperature and humidity changes. With increased moisture, it rots, shrinks and cracks. And for a greenhouse, such flaws are unacceptable. The service life is maximum two years with constant rework and repair.

Metal is a strong and durable material. However, working with him is more difficult. Here you will have to use welding, a pipe bender, and a grinder. However, such a framework will last forever. Corrosion from moisture can simply be tinted with paint.

Plastic is an easy material to work with. However, its lightness can play a cruel joke in winter. Such a structure can simply break, and completely fly away from gusts of wind. When installing, it is worth taking into account the size of the frame and adding it to the drawing.

The foundation

The setting of the foundation depends on the size of the greenhouse. If this is a low greenhouse-bread bin, then there is no need for it. But if it is planned to build a high greenhouse, then it must be connected to the ground by means of a foundation. It can be wooden, brick, jellied. Often the manufacturer suggests using pins to hold the greenhouse in place.

The method of strengthening depends on the size. For an average greenhouse, point reinforcement with pins or a wooden bar is suitable. But high greenhouses are reinforced with a concrete foundation.

Sheet sizes

The distance between the arcs of the frame depends on the size of the sheets. It should be borne in mind that the sheets must have a minimum number of joints when joining. They must be installed so that excess water can easily drain through them.

Greenhouse shape

There are several types of greenhouse shapes.

- Arch. The most convenient and economical option.It's easy to install. This design is convenient because snow does not accumulate on it in winter, hence the longer the operating time. The weak point is the narrowing towards the edges, which limits the planting of some crops.

- With a pitched roof. This is a classic house shape. It will take longer to work with such a design. However, the convenience in planting plants and the absence of restrictions will become her strong point. The slope can be either on two sides or on one.

- Greenhouse-bread bin. It is presented in the form of a low semicircle greenhouse with a sliding cover. It is convenient for planting low-growing creeping crops, often used for growing seedlings.

- Dome. It is difficult to install, but it has a beautiful appearance, which will help it become a decoration of the site. This design is well lit.

- According to Meatlider. This is a popular form, but difficult to install. In the greenhouse, the north side is forty centimeters higher. This design has high ventilation and prevents cold air from entering the greenhouse.

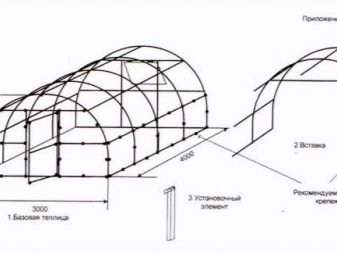

Taking into account all these nuances, you can start building a drawing and installing a greenhouse. All work begins with the construction of the drawing. The first is to designate the foundation, namely to calculate the width, length and height of the structure. Further, everything leading from it - the frame, doors, windows, while taking into account all the components.

Installation and assembly

When installing, you should pay attention to the place where the greenhouse will be located. The ends should face east and west. In this case, the lighting will be uniform and maximum throughout the day. It is worth choosing places illuminated by the sun all day so that nothing interferes and does not shade, this is a guarantee of warmth and quick seedlings of the crop. And you also need to avoid places with a draft. A prerequisite is the correspondence of the size and the space allotted for the greenhouse with an even surface.

DFirst you need to prepare the base - level the ground, remove excess vegetation. The foundation is installed by driving in pegs at the corners and the thread tension is calculated at right angles. For measurements, you should use a tape measure. Next, the foundation is laid from the selected material. Then the frame is installed, depending on the drawing. Be sure to tie it to the foundation using staples. For the frame, you should stock up on profiles.

Next, you need to start connecting the polycarbonate sheets to the frame. The most important point is the installation of the first sheet, because the rest of the connection will go from it. You need to install it with an outlet 5 cm down. Self-tapping screws with a cap or a rubber seal are used for attachment.

The following sheets are installed with an overlap on the installed one. The carbonate sheets are attached to the base last so that the position can be corrected. You can seal the joints with sealant or aluminum tape. This is especially necessary if the greenhouse will be all-season.

Gutters can be installed to better get rid of moisture between the gaps. At low temperatures, water can freeze, and polycarbonate can burst from constriction.

To install windows and doors, the sheet is cut to the desired size. Additional ventilation holes should not be neglected, as polycarbonate does not allow air to pass through well.

This should be done last of all of the remaining materials. In case of a shortage, it will be possible to purchase it. The interior arrangement depends on the wishes of the gardener. Will it be beds or shelves for flowers, pins for curly or special threads - only the owner decides, well, and the culture for which the greenhouse was built. In year-round greenhouses, it is necessary to supply electricity and make an outlet.

Successful examples and options

The classic curved greenhouse is always welcome on the plots. Despite its shape, it is roomy and allows you to combine different cultures. They also create small half-arc greenhouses for seedlings.

The conical greenhouse will become a decoration of the site.And if you install it in the yard, it will become a wonderful flower garden. This design allows you to create entire ensembles.

Gable and gable greenhouses are convenient for tall plants.

For greater roominess and decoration of the site, polygonal greenhouses are created. Their top can be five-, six- or octagonal.

A well-executed design will be not only a heat-preserving component, but also a decoration of the garden. A greenhouse is a necessary object on the site. The harvest depends on its design. By trapping light, heat and moisture, it allows you to harvest more crops. A big plus in self-assembly is that you can independently choose the shape and size, which is important in non-standard areas.

In this video, you are waiting for the installation of a polycarbonate greenhouse.

The comment was sent successfully.