Features of the device for greenhouses

In order to obtain a high yield in the greenhouse, it is necessary to provide the correct ventilation mode. The vent will do a good job with this task. Such a design must be of high quality and highly efficient. To achieve this result, you should familiarize yourself with the features of the device for greenhouses.

Peculiarities

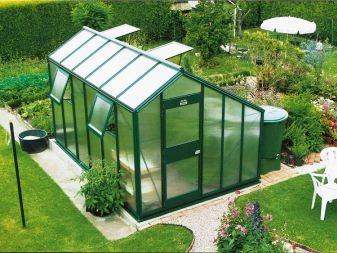

Dachas equipped with greenhouses have always delighted their owners with a large harvest. In winter, in polycarbonate greenhouses, the most popular at present, the conditions for keeping plants are optimal. But with an increase in solar activity in spring and summer, the situation changes.

Polycarbonate transmits light very well, but at the same time does not allow air to circulate.

The temperature in the greenhouse becomes too high and can be detrimental to the plants grown in it. Therefore, in such a design, the window is especially important.

The moving part of the greenhouse intended for ventilation is called a window. This device allows you to create your own microclimate in the greenhouse, which has a beneficial effect on the cultivation of various kinds of vegetable crops.

The window has the following features:

- prevents the risk of condensation;

- ensures the correct movement of air masses;

- eliminates strong overheating of the air in the greenhouse during the day;

- minimizes the temperature difference between day and night;

- will allow for the adaptation of plants, before planting in open ground.

The window in the greenhouse will prevent the emergence of wood lice, aphids, slugs, all kinds of pests and bacteria that always appear in warm and humid rooms. Greenhouses in which the indicated conditions are observed will delight you with an excellent harvest.

Device

The device of vents in greenhouses may differ in size, location and opening mechanism. The last characteristic is the most significant. To organize good air circulation, it is possible to use natural or forced ventilation.

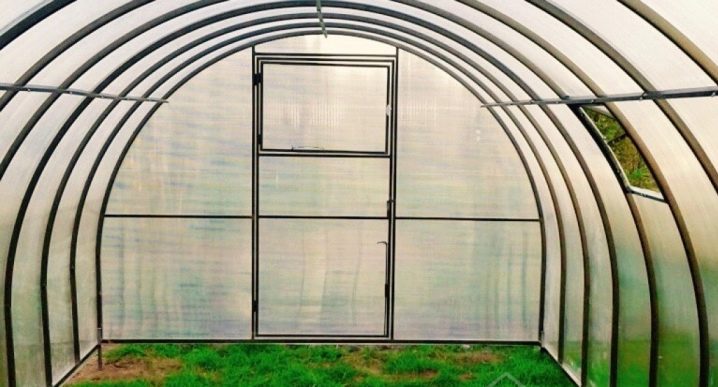

In a self-made film or glass greenhouse, the simplest and cheapest way to equip the greenhouse with the correct microclimate is usually used - natural ventilation. Natural ventilation means providing air exchange through open doors, windows, vents. The overheated and humid air of the greenhouse is gradually replaced by the fresh, outdoor air.

Considering that hot air tends to rise, you should equip a window on the roof, and the side position of the door will provide air flow.

Such ventilation will sufficiently provide good conditions in a small greenhouse, but requires mandatory human control. However, for large greenhouses, this ventilation will not be enough.

For large greenhouses, forced ventilation is provided. This ventilation is equipped with a fan. An exhaust fan is installed at the top of the structure, the power of which must be sufficient to effectively remove hot air. Air supply devices are installed on the walls, taking into account the location of the plants. Direct flow of colder air masses can harm them. This ventilation device is most often used in addition to natural ventilation and does not exclude human control.

The complete absence of manual adjustment of the microclimate in the greenhouse can be ensured by an automatic ventilation system.

Automation

Automatic systems that carry out ventilation in the greenhouse are divided into the following categories:

- hydraulic;

- bimetallic;

- electrical.

Hydraulic

Automatic opening of the air vent on a hydraulic drive is reliable. This lever system can be purchased at the store or made by yourself.

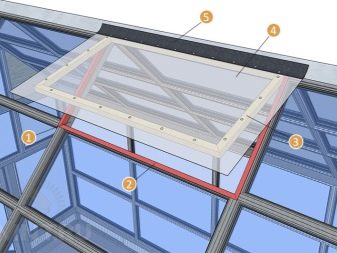

The principle of operation of the mechanism is based on the ability of liquids to expand when heated. Factory devices include a hydraulic cylinder with a liquid (paraffin or oil) and a movable rod that connects to the window. When the air in the greenhouse is heated, the liquid in the hydraulic cylinder expands and pushes the rod, which gradually opens the window. The air cools down, the liquid narrows and the window is closed.

The DIY system works like communicating vessels.

One of the vessels is located at the bottom and acts as a thermostat. It is sealed, half liquid, half air. Another vessel is located at the top and acts as a weighting agent. The leaf of the window must be fixed on a rotating central axis. On one side of the sash, a weighting agent is installed, on the other - a counterweight.

When the temperature in the greenhouse rises, the air in the lower vessel expands and pushes the liquid into the upper vessel, and the window opens. When the temperature in the greenhouse drops, the system works in reverse order and the window closes.

This design can be done using conventional plastic bottles.

This is the simplest, but at the same time effective automatic window opening system. To create it, a minimum of effort and materials is spent.

The disadvantage of such a system is the long cooling of the liquid. With a sharp cold snap, the window will close for about 20-30 minutes. Hypothermia can be detrimental to cucumbers and other crops that cannot tolerate cold.

Bimetallic

Bimetallic ventilators consist of two metal plates with different expansion rates when heated. Hot air in the greenhouse heats up the plates and one of them bends into an arc, opening the leaf of the window. When the air cools down, the metal returns to its original state and the device closes.

It is quite simple to make bimetallic automation yourself. The materials that are required for manufacturing can always be found at their summer cottage. You will need two metal plates: vinyl plastic and roofing iron. They stick together. One end is fixed, and the other is connected by a rod to the leaf of the window. The result is a pretty good automatic system. The only drawback of this drive is the low power level, so it is only suitable for lightweight structures.

Electrical

The electric type of ventilation is equipped with temperature relays and fans. When the air overheats, the relay is triggered and turns on the hood. This system is powerful, compact and reacts quickly to temperature differences. A significant disadvantage is dependence on electricity. If this type of ventilation is used in the greenhouse, the purchase of backup power supplies will be required.

To protect plants from overheating, in the event of a power outage, the use of alternative energy sources (solar panels, wind power) will help. Due to the need to purchase additional elements, these systems are expensive. But there is a possibility of choosing the power of the electric motor. For heavier structures, you will have to spend money on a strong drive, and for light ones, low-power ones are suitable.

Dimensions (edit)

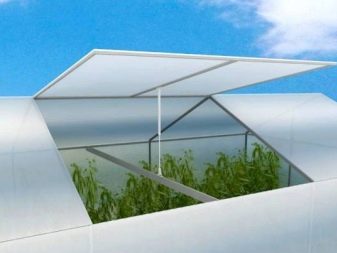

In order to correctly organize the ventilation in the greenhouse, it is necessary to correctly calculate the size and number of vents. The area of the openings with flaps should be 20-30% of the floor area in the greenhouse.Experts advise placing one ventilator for every two meters.

Greenhouses measuring 3x6 meters are quite popular among vegetable growers. There is an opportunity to install a structure with a length of 6 meters on almost every site. When creating ventilation in a greenhouse of this size, you need to equip 3-4 vents measuring 400x1200 mm.

To simplify the installation of the vents, the size and shape are usually adjusted to the opening between the two adjacent frame elements. If it is necessary to install a structure of a smaller size or of a different shape, a separate frame is made for it, using the same materials as for the base of the greenhouse.

How to make it yourself?

Having familiarized yourself with the features of the device of the vents, you can make a homemade device from available tools. First, you need to choose the right place for the future structure, taking into account the location of the frame rails and the physical properties of the air.

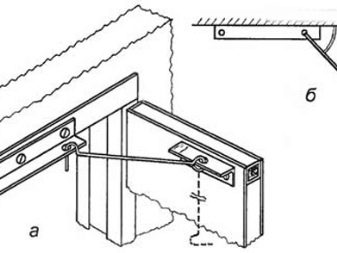

As a rule, the window structures are fixed on the outside with pivoting hinges. The fastening mechanism will not greatly affect the microclimate in the greenhouse. But if in the future it is planned to use an automatic device, it is necessary to think in advance about the method of its fastening.

When all the drawings and calculations have been made, it is necessary to prepare the material and tools.

To work, you need the following components:

- hacksaw for metal;

- cutter knife;

- screwdriver;

- self-tapping screws with a seal and a wide head (such screws will prevent water from entering the greenhouse during rain);

- a file to process the edges of the profile;

- connecting parts for fastening the profile.

When creating a window, you should adhere to the following sequence:

- first, a hole is cut in the right place; you should act carefully, taking into account the dimensions with all the allowances;

- the base for the lathing is cut, the sides of the frame should be 0.5 cm less than the sides of the opening for the window;

- by tightening the profile with mounting tape, stiffeners are created in the corners, and if this is not enough, a diagonal rail is added;

- fitting is done, if everything suits, the sharp corners of the structure are sanded with a file;

- the frame is covered with a primer or ordinary paint and connected to polycarbonate;

- all holes in the sheet must be covered with sealant or other means;

- the edge of the hole is pasted over with rubber and the sash is installed in place;

- hinges, shutter and stop are fixed.

A simple hydraulic system made from a car's shock absorber can be added to the design. Engine oil will act as a liquid that will react to temperature. To create a hydraulic automat with your own hands, you will need a car shock absorber rod, a gas spring, a cylindrical metal pipe for oil and two taps.

The shock absorber piston is attached to the desired window.

Cranes are attached to the pipe on both sides. One will work to fill the oil, the other to drain, and also to adjust the pressure in the cylinder. A neatly cut spring connects to the oil cylinder.

Now, when the temperature in the greenhouse rises, the oil in the pipe will expand and push the rod out, thereby opening the window. When the temperature drops, the oil will regain its previous volume and the sash will close. The design is considered low cost and easy to implement.

Advice

To provide the greenhouse with a competent ventilation system, it is necessary to familiarize yourself with the recommendations of specialists. Knowing the intricacies of operating the vents, you can be sure of a good harvest and uninterrupted operation of the device.

- Quite often, greenhouses are divided into several parts by a partition. To provide the building with good ventilation, separate vents must be arranged in each section.

- The location of the greenhouse itself plays an important role in the calculation of ventilated areas. More vents will be needed if the area where the greenhouse is located is humid.Even in a factory design, it is worth increasing their number.

- When organizing the vents, the wind rose should be taken into account. Auxiliary openings should not be located on the side where the wind is constantly blowing. If this condition is not met, there will be a strong draft in the greenhouse.

- It is necessary to provide the window with a restricting chain. In case of an unexpected gust of wind, the structure will not be damaged.

- The vents in the greenhouse may not be enough. This is determined by the presence of condensation. If drops appear on the walls of the greenhouse, you need to add additional windows.

- In case of bad weather conditions (strong wind or heavy rain), end vents can be installed. Such ventilators will help to avoid strong drafts.

In order to exclude unnecessary costs of forces and materials, it is necessary at the stage of drawings and calculations to think in detail about all the subtleties of the ventilation system.

The quality and quantity of the crop depends on the operation of this device in the greenhouse.

For information on how to independently install a window in the greenhouse, see the video below.

In practice, most greenhouses have a window in their doors. Sometimes a problem arises with the installation of a drive for the window, which is often combined with the contour of the door, which makes it impossible to open freely - the drive of the window interferes. The solution to this problem is to install a door shed at the point of attachment of the drive to the door frame, then it becomes possible to open and close the door together with the window.

The comment was sent successfully.