What is a cotter pin and where is it used?

Despite the more than widespread distribution of a wide range of various fasteners, many are interested in what cotter pins are and where exactly are they used? A cotter pin (from the German Splint) is a fastener (in some cases elastic) made of metal in the form of a semicircular rod. It is bent in half and has an eyelet at the bend. Such devices are used to connect parts under low stress, as well as to prevent the nuts from loosening.

What is it and what is it for?

Cotter pins, as a type of fastener, are standard hardware products. They are widely used in a wide variety of designs, devices and installations. It should be noted that their main task is to securely fix the axles and nuts. Splitting works according to the principle of a quick-lock mechanism. These hardware, used for fastening individual parts of walk-behind tractors, snow blowers augers and even for assembling furniture, are very easy to install and dismantle.

The main advantages of cotter pins can be safely attributed to maximum reliability, due to which the risk of loosening of threaded connections is prevented even at peak loads and vibrations.

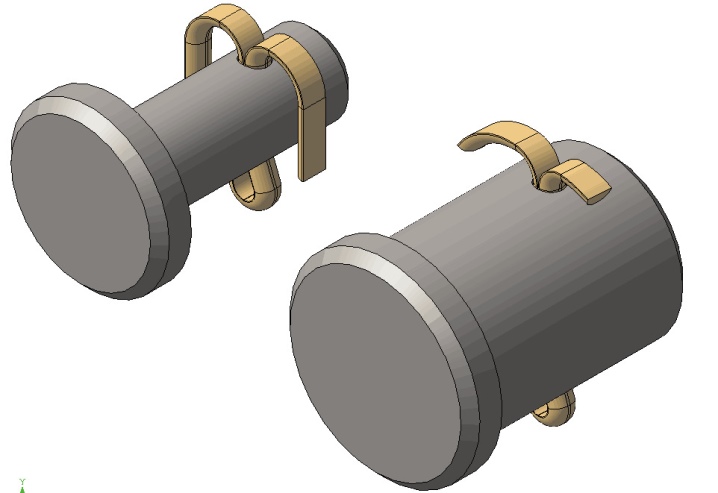

Externally, a cotter pin is a small wire rod that has been bent in half. It has a semicircular cross-section and fits into an appropriately sized round hole. The latter can be done in an axle, shaft, bolt or nut. In the place where the cotter pin is bent, there is a small eyelet that prevents it from slipping. After installing the fastening element, its ends, which have different lengths, are spread in different directions and bent.

Considering the features and performance of this type of fastening devices, it is necessary to pay attention to their difference from pins. First of all, the latter are made in the form of a rod having a cylindrical or conical shape. By and large, a pin is a nail that does not have a head. In the overwhelming majority of cases, such latches are inserted into holes that go through all the connected elements of a structure or mechanism. So, the pin in the form of a cylinder of increased diameter is pressed into the bore with force, which provides a reliable frictional connection due to the elasticity of the material.

Pins are used in situations where strict fixation of structural elements in relation to each other under light loads is required. Often, in this case, additional transversely placed cotter pins are installed, which ensure a reliable connection and prevent the pins from falling out during vibration.

One of the important points in this case is the maximum simplicity of both installation and dismantling. It is enough just to knock out the rod from the back side.

In practice, two types of devices under consideration are most often used - spring and extension... Moreover, the latter are the most common due to their reliability, simplicity of design and the possibility of self-production. The spring cotter pin in the form of a zigzag is a little folding in operation, but at the same time it is not less reliable.

These hardware have proven their effectiveness in situations where it is required to protect loose screw or bolted connections from axial displacement under external influences. At the same time, spring models are more relevant for increased loads. In this case, we are talking about units of construction equipment, including lifting mechanisms, as well as brake systems for bicycles. Typically, spring cotter pins are additionally secured to prevent slipping and loss.

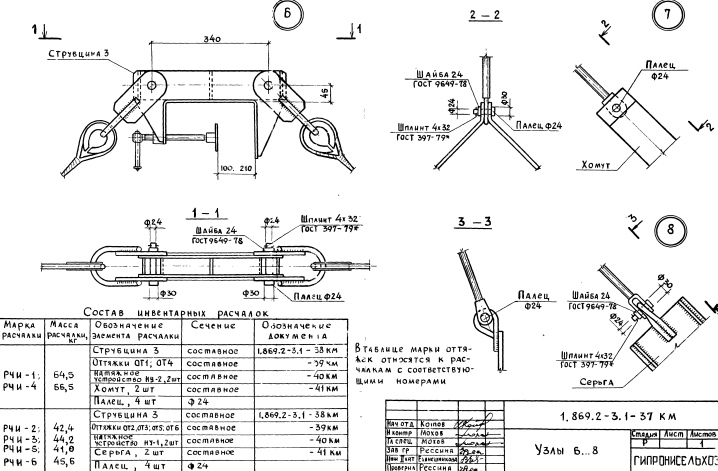

In mechanical engineering, the described devices are widely used as plugs and retaining fasteners. However, they can be found in everyday life, almost at every step. Gym equipment is a prime example. Another type of cotter pins, namely, quick-release ones, are widely used in the agricultural sector.

They are indispensable if frequent assembly and disassembly of various structures is required.

Taking into account all of the above, it is possible to conditionally determine the scope of application of cotter pins of different types. And in this case we are talking about the following areas.

- Cars, motor vehicles, watercraft and bicycle equipment.

- Mechanical engineering.

- Manufacture of metal structures.

- Agriculture.

- Crafts.

It is important to consider that the installation of cotter pins does not provide for the transfer of energy. The list of modern hardware products includes a sufficient number of elements, such as, for example, lock nuts. However, even the highest quality ones weaken over time and under the influence of vibration. Prevention of such phenomena is the main task of the cotter pin. However, it is worth considering the applied force, which, at peak loads, can destroy the entire structure.

Species overview

Despite the simplicity of the fastening devices under consideration, there is a fairly wide list of their varieties. The performance and characteristics of each type should be considered when choosing hardware products.

Craftsmen specializing in the repair and maintenance of various equipment have whole sets of fasteners.

These include wire, tubular, and other clamps. Depending on the shape, the following types of cotter pins can be distinguished.

- Straight, which are standard and related to adjustable. They are made by bending the wire, they can be made by hand with a minimum arsenal of tools.

- T-shaped, having not an eyelet at the bend, like straight lines, but a jumper.

- Needle or spring, with a single or double eye.

- Ring (classification according to DIN 11023), representing the so-called agricultural check. They are made in the form of twisted rings with a straight rod or with a protrusion.

- Furniture, which can be wooden.

It is important to take into account that all the key features of a particular category of cotter pins are displayed in their marking. All hardware products, taking into account their size and shape, are classified in accordance with the current GOST 397-79, which is analogous to the German DIN-94.

Wrench

This type of fixture is the most common. Such cotter pins have “legs” of different lengths, which are spread in different directions to fix the fastened elements. When folded together, they form a circular cross-section. The head (eyelet), which has an almost round shape, limits the depth of planting of the hardware.

When connecting parts and fixing nuts, the adjustable cotter pin is inserted into the corresponding hole.

The different length of the legs greatly simplifies the process of unbending them. The shape of the head makes it easy to remove the retainer using not only pliers, but also thin screwdrivers, awl or any rod of a suitable diameter. With all their obvious advantages, standard cotter pins have one important drawback. Their reuse is undesirable, since in this case the performance is significantly reduced.

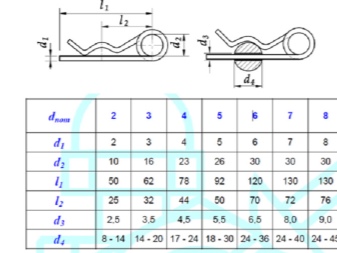

Spring loaded

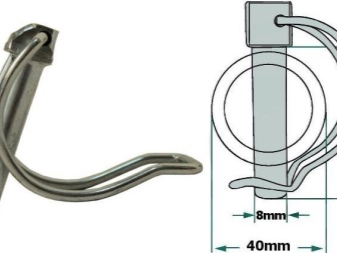

These clamps differ from adjustable clamps in shape, as well as in the principle of operation. Blocking of the connected parts in this case occurs due to snappingprovided by the spring effect of the material from which the cotter pin is made. In their shape, such products resemble the letter "R", and their production is regulated by the norms of the international standard ISO-7072.

The straight part of the cotter pin is inserted into the hole, and its wavy leg snaps into place from the outside in several places. This creates the aforementioned spring effect. Taking into account the design features, such hardware products are often called needle spring products. Depending on the shape of the curved leg, types such as "E" and "D" are distinguished.

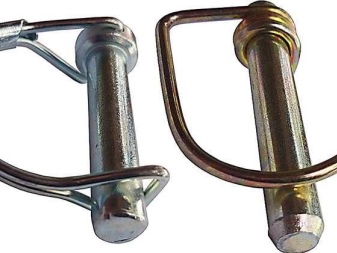

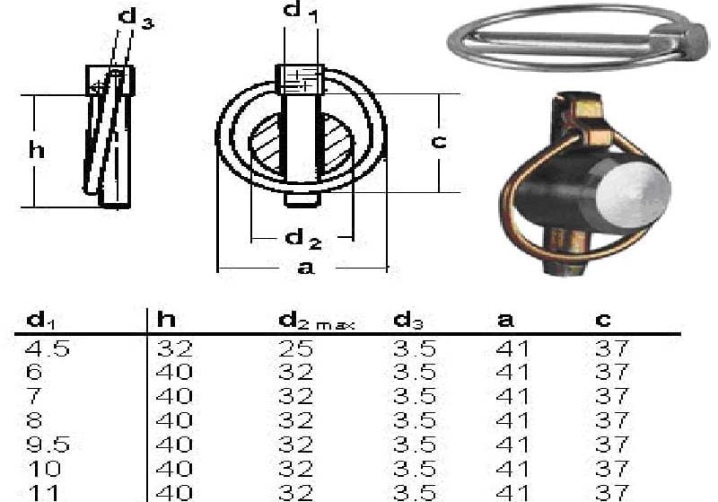

Quick release ring

The connecting elements, according to German standards in the category DIN 11023, are equipped with special rings. They greatly simplify the use of cotter pins, especially when multiple installation and removal is required. Such quick-release checks differ from other types of hardware primarily in that they can be used almost an unlimited number of times when assembling and disassembling mechanisms and structures.

This is most relevant for parts that have special requirements in a safety context. Most often, cotter pins with a ring can be seen on agricultural machinery.

The shape of this type of product is enshrined in the relevant standards. This allows you to control the quality and performance of hardware elements. It should be noted that there are quick-release cotter pins of a special shape, to which special requirements are imposed.

Materials (edit)

Taking into account the design features, purpose and scope of the described clips, it can be concluded that the materials from which they are made must meet certain standards. Now on the market there are split pins, including those made of copper, brass and aluminum alloys. It is worth noting that such options are much less common. In this case, the most common material is mild structural steel and stainless steel.

For example, spring-type clamps (plugs) in the overwhelming majority of cases are made of carbon and stainless steel. They are zinc-plated for effective corrosion protection. Its thickness ranges from 6 to 12 microns. It is important to take into account that in accordance with GOST 397-79, the surfaces of hardware products should not have cracks, chips or other damage, due to which the permissible roughness standards will be exceeded.

According to current standards, the following material and coating options are recommended for the manufacture of cotter pins.

- Low-carbon steel (carbon content in the composition is not more than 0.2%) with a zinc, cadmium, oxide or phosphate protective layer.

- Corrosion-resistant steel grades with an oxide coating created by acidic solutions.

- Nickel-plated brass, grade L63.

- Alloy AMTs with an oxide coating filled in a solution of potassium dichromate.

There are certain technical requirements for both the base material and the applied coatings (GOST 9.301-86).

As mentioned above, in addition to low-carbon steels, even non-ferrous metals and their compounds can be used. So, when making cotter pins from wire, the absence of coating on the ends of the "legs" is allowed. In addition, in some cases, it may be absent on the inner surfaces of the branches, namely, at the points of contact.

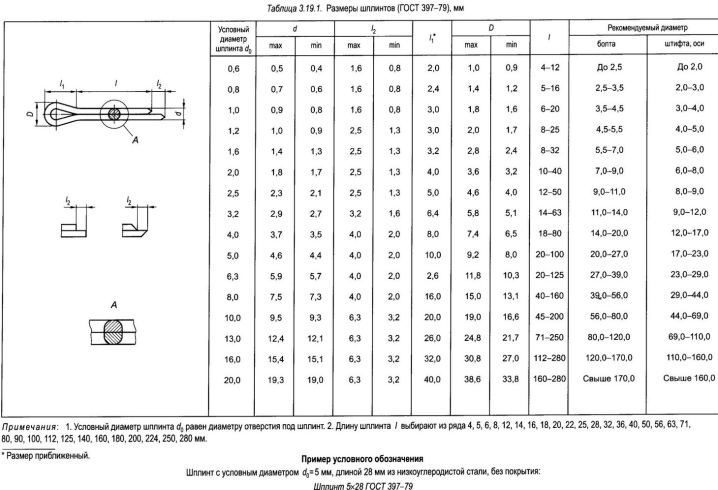

Dimensions (edit)

First of all, it should be noted that the cotter pins are selected taking into account the size of the mounting holes of the fastened or fixed parts. As already noted, the main parameters of a hardware product are displayed in its marking. For example, the cotter pin 5Х28,3,0363, according to the current standardization (GOST 397-79), has a length and diameter of 28 and 5 mm, respectively, and is also made of L63 brass with a nickel coating with a thickness of 6 microns.

For different types of clips, there are tables of their sizes, which can be easily found on specialized sites. In this case, the key criterion will be the coincidence of the diameters of the cotter pin and the holes for it. It is important to take into account that the clearance should facilitate the free pushing of the fastener. It is also necessary to take into account the length of the legs, which should be at least twice the length of the hole.

The drawings and special tables indicate the parameters of the cotter pins to be installed.

So, the diameter of the classic, that is, the adjustable latch, is understood as the diameter of the hole in the connected, fastened elements of the structure or mechanism, which is possible for its installation. In this case, the length is measured from the ear along the short leg. By the way, the edges of the latter can be pointed or cut at a certain angle. Most often on sale you can find a cotter pin of the following sizes:

- DIN 94 - diameter 1-13 mm, length 4-200 mm, head 1.6-24.8 mm;

- GOST 397-79 - diameter 0.6-20 mm, length 4-280 mm, head 1.6-24.8 mm.

How to install?

Regardless of the type and design features, the described devices are used in order to fasten axles, shafts and threaded connections under relatively low loads. In principle, the process of installing the clips is as simple as possible. However, there are certain rules and features. Adjustable and spring cotter pins can be installed in two ways - parallel or perpendicular to the axis of attachment of parts.

A classic hardware product must be passed through the corresponding hole and its "antennae" bend in different directions.

The needle (straight) part of the spring cotter pin goes through the hole, and its wavy branch is pressed against the outside of the part. Typically, these types of fasteners are used only once. An alternative in this case can be ring, quick-detachable models that are reusable.

Dismantling the clips, as well as their installation, should not cause any significant difficulties. Most often, it is enough to simply pull out the cotter pin or knock it out using a nozzle of the appropriate size. As a last resort, the fastener can be carefully drilled out by picking up a drill.

How to tighten the cotter pins correctly, see below.

The comment was sent successfully.