Selection and use of pulleys for a walk-behind tractor

For many decades, agricultural workers have been using a walk-behind tractor, which greatly facilitates the performance of heavy work with the ground. This device helps not only to plow, but also to harrow, plow and huddle. The electrical apparatus consists of a large number of main and auxiliary parts. One of the important parts of the walk-behind tractor is the pulley, which transfers the rotating speed from the motor to the attachment through the belt. This device enables the apparatus to move in different directions. In specialized stores, you can see pulleys that differ not only in size, but also in the material of manufacture. Before buying the necessary part, you need to consult with experienced craftsmen or store consultants so that the purchased part does not turn out to be unnecessary and useless.

Description

In walk-behind tractors, designers use a belt drive, which consists of two pulleys, a belt and a tensioner.

Advantages:

- high speed of work;

- overheating protection of drive units;

- simplicity;

- reliability;

- low cost;

- lack of noise.

Disadvantages:

- frequent belt replacement;

- pressure on shafts and bearings.

The pulley is the main part of the gearbox, which is located on the central shaft of the engine. The appearance of the part resembles the shape of a wheel, interacts with other elements through a special belt.

You can buy these devices in different sizes from specialized stores. Most of the parts are made of aluminum, steel, cast iron and duralumin, they have high strength and reliability. To reduce the cost of goods, some manufacturers use plastic, plywood and textolite for production.

Experts do not recommend purchasing products from the second group due to their short service life and low quality.

The main criterion when choosing a part is the size of the belt. The size of the pulley depends on it.

Technical requirements for belts:

- strength;

- wear resistance;

- minimum bending stiffness;

- maximum index of friction on the surface of the pulley.

Types of belts:

- flat - have a small thickness and cross-section, in the manufacturing process they are glued from separate parts of the fabric;

- woven - have a thickness of up to 1 cm and are made of nylon fabrics impregnated with polyamide and rubber;

- rubberized - are made of anid cord and have a thickness of 10 mm;

- synthetic - have a thickness of up to 3 mm and a glued joint.

And there are also round and V-belts.

Varieties

Manufacturers release three types of pulleys for motoblocks:

- disc - have a size from 8 to 40 cm;

- with needles - have a diameter from 18 to 100 cm;

- monolithic - two-strand have a size of 3 cm, and three-strand 10 cm.

There are two types of bore:

- cylindrical;

- conical.

All pulleys have 8 grooves, the speed of wear of the working belt depends on the quality of grinding.

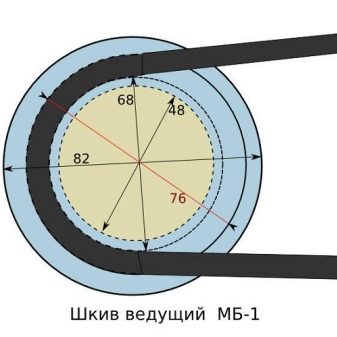

Pulley types depending on the gearbox type:

- slave;

- leading.

For motoblocks with attachments, it is necessary to purchase pulleys with a diameter of 19 mm, and for more complex high-speed devices, pulleys with a diameter of 13.5 cm or more will be needed.

Self-production

If it is impossible to purchase a finished pulley, professional craftsmen advise you to make this part yourself.

To make a spline pulley at home, you need a lathe and a metal workpiece. For help, you can turn to turning workshops, where professional turners will definitely help you turn the necessary part.

If it is impossible to get a metal blank, experts advise using a piece of plywood.

Required tools:

- electric jigsaw;

- milling cutter;

- compass;

- electric drill.

Manufacturing steps:

- purchase of the necessary workpiece;

- drawing a circle of the required diameter;

- drilling a central hole;

- cutting a circle with a jigsaw strictly along the marked line with an indent from the line by 20-25 mm;

- grinding the resulting workpiece with fine sandpaper;

- cutting a groove for a belt using a cutter of the required size;

- installation of the finished product in the walk-behind tractor;

- elimination of all defects and inaccuracies.

This plywood part has a short lifespan and requires constant inspection and replacement if necessary.

It is possible to install homemade parts only on those walk-behind tractors in which this manipulation is provided by the developers.

Experts recommend resorting to self-manufacturing of a pulley only in the most extreme cases and, if possible, immediately replace a part made in an industrial environment on special equipment.

Care

To extend the life of the walk-behind tractor, experts recommend knowing and applying a few basic rules for pulley care:

- regular checking and cleaning of the protective casing from stones, dust particles, earth and other debris;

- constant verification of the reliability of fastening the part to the axis to prevent thread wear;

- compliance with all rules and regulations for the operation of an electrical device;

- alignment check with a laser level;

- checking the device for mechanical damage, as well as cracks and scratches.

To prevent the development of corrosion processes after operation, it is necessary to put the walk-behind tractor in a dry and ventilated room, protected from the ingress of various precipitations.

In order to remove the pulley and correct the beating of the starter, you must first reduce the stroke, reduce the speed, and then completely stop the apparatus.

Before starting the process of performing the planned work, it is imperative to check the serviceability of all elements of the walk-behind tractor to prevent the occurrence of unpleasant situations that can lead to breakdown of the entire walk-behind tractor.

Experts recommend regularly conducting a comprehensive check of the entire apparatus, which will certainly have an impact on the service life of all parts, including the pulleys.

The main activities of a comprehensive technical inspection:

- regular cleaning of all working units;

- checking air filters;

- regular replacement of deformed parts;

- checking spark plugs;

- oil change;

- lubrication of parts of the control system;

- clutch adjustment;

- muffler change;

- belt tension adjustment.

A walk-behind tractor is a universal device that is used not only by farmers, but also by ordinary residents who have personal plots. This unit is a multifunctional device that makes it possible to remove snow, mow grass and lawns, transport goods, pump water and clean streets. To perform various types of work, it is enough just to change attachments. This process takes a short period of time and has a simple technology. The stable operation of the device is ensured by a large number of different parts. One of the most important elements in a walk-behind tractor is the pulley. A simple round-shaped part is the link between the motor and the moving parts. The whole process of work depends on the work of the pulley.

See below for more details.

The comment was sent successfully.