How to make a mini tractor from a walk-behind tractor?

Mini tractors are a type of agricultural machinery that is widely used in personal subsidiary plots. However, the ready-made designs that the industry can offer do not always suit consumers. And then homemade devices come to the rescue.

Peculiarities

To make a mini-tractor from a walk-behind tractor, you must take into account its characteristic features. The vast majority of structures used in practice are supplemented by attachments of various types - primarily arrows, buckets and plows. At the same time, mini-tractors are characterized by high cross-country ability, they can operate equally effectively in parks, on lawns and lawns, on asphalt, in a garden, and so on.

The advantage of mini-tractors is also the minimum consumption of fuel and lubricants.

The high maneuverability of small equipment allows you to carry out a variety of jobs, even where more powerful machines will not pass. At the same time, a mini-tractor is significantly stronger than a walk-behind tractor, which allows you to confidently use it to move various loads.

Unlike walk-behind tractors, a mini-tractor requires a special storage room.

A full-fledged mechanical transmission is always installed on mini-tractors - there is no special need to install different types of chassis. The power units installed by default on the walk-behind tractor are guaranteed to have to be changed. Their capacity does not meet the necessary requirements.

Both two-stroke and four-stroke gasoline engines installed on walk-behind tractors of various brands do not produce more than 10 liters of effort. with. For a mini-tractor, the smallest allowable force is 18 liters. with. If diesel engines are installed, then it can reach 50 liters. with.

But just replacing the engine will not work. It is imperative to change the transmission..

None of the types that are used on walk-behind tractors are suitable. It is necessary to install a friction clutch - this is what the developers of modern miniature tractors recommend. The peculiarity of such a device is that rotation occurs due to friction between the driving and driven elements of the clutch.

The two-wheeled undercarriage is most often changed to a four-wheeled version.

Caterpillar structures are occasionally encountered. The differences are manifested in the governing bodies. If on walk-behind tractors they concentrate on the handle to make it more convenient for users, then a full-fledged steering wheel is installed on mini-tractors. At the same time, we must not forget that the dashboard also contains buttons and levers that perform auxiliary functions.

Developers of walk-behind tractors provide for special brackets or power take-off shafts for attaching auxiliary devices. But for a mini-tractor, this solution will not work. It must be designed differently so that the placement of any additional components does not cause problems.

Even if you do not delve into the technical differences between the walk-behind tractor and the tractor, it is impossible to ignore one more point - the mini-tractor must have an operator's seat; it is not always on the block. But still, for technically trained people, all these corrections are not difficult.

Not all motoblocks, however, allow you to do this equally successfully.Sometimes you have to either abandon your idea, or significantly degrade the technical characteristics of the device. It's not just about the right motor power. Much better chance of success if it runs on diesel... These engines allow you to successfully process large areas, using less fuel.

Attention should also be paid to the mass of the original walk-behind tractor. High loads require a much heavier device. Elementary stability depends on this. Since those converting agricultural machinery strive to save money, there is no point in purchasing very expensive block models. That's why preference should be given to affordable high power modifications that are equipped with a minimum of options... All the same, these additions will be added during the rework itself.

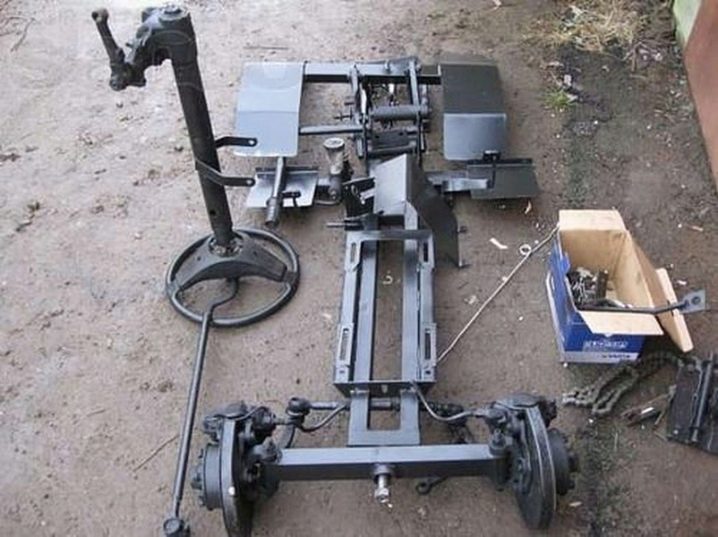

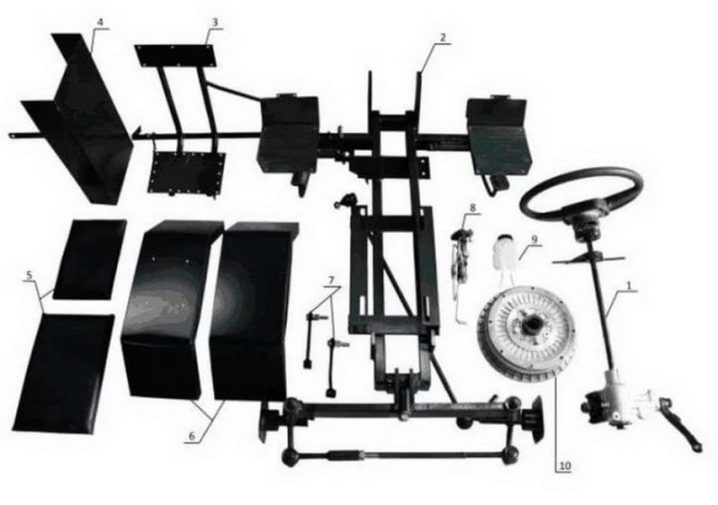

Conversion kit

The differences mentioned above complicate the conversion of motoblocks into mini-tractors somewhat. A special conversion module comes to the rescue. Using it, you don't have to look for single parts, you don't have to think about how to make individual elements of the tractor.

Using the kit "KIT", you can get such three advantages as:

- abandon the clamping of hinged parts;

- avoid strong vibration vibrations;

- Simplify your work in the field to the limit.

A special feature of "KIT" is the connection of the rudder through a worm-type gearbox. And also for control, steering rods with standard tips are used.

The kit includes a drum format brake set, driven by hydraulic fluid. The accelerator is manually operated and the brake / clutch complex is coordinated by the pedals. The developers of the conversion module have provided for the orientation of the gearbox towards the driver, it is placed on the frame.

Attached and attached devices are attached using a separate attachment. The kit "KIT # 1" includes a mount that allows you to install a lawn mower and a shovel (snow blade). It also includes front Zhiguli wheels.

I also need to mention such details as:

- frame;

- base for the seat;

- the seat itself;

- driver protection;

- back;

- mini tractor wings;

- levers that lock and unlock one of the axle shafts;

- brake cylinder;

- hydraulic reservoir;

- drum and platter.

The rear axle and auxiliary attachments, as well as the front wheels are not included in the KIT. As for the tools, they are selected individually.

But in any case, the following are needed:

- hammers;

- electric drills;

- keys;

- welding machine and electrodes to it;

- Angle grinder;

- fasteners;

- clamps;

- square;

- drills for steel processing;

- circles for metal.

The choice of wheels is at your discretion. You can use both car wheels and wheels installed on a walk-behind tractor of a similar format.

The cost of ready-made kits for converting motoblocks into mini-tractors varies on average from 60 to 65 thousand rubles. Of course, additionally purchased devices can significantly increase this amount. By varying the set of auxiliary components, it is possible to change the total amount of costs.

How to redo?

If you decide to create a mini-tractor with your own hands on the basis of the Crosser CR-M 8 or "Agro" walk-behind tractor, you must use the following set of equipment:

- bearing frame;

- semiaxis locking levers;

- seat with support;

- steering wheel;

- a cover that prevents the driver from getting injured by contact with the rotating belts;

- wing protrusions that prevent the ejection of dirt from under the wheels;

- brake cylinder and drum;

- tank for brake fluid;

- semiaxis locking levers;

- lifting device (behind);

- installation for fixing the soil cutter.

Before work, you should thoroughly study the instructions for the walk-behind tractor.

When the device is equipped with an electric starter, you need to prepare a 200 cm cable with a cross section of 1 cm.

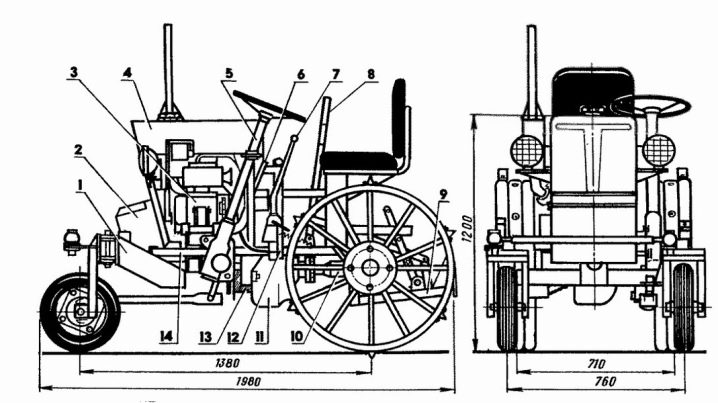

From the walk-behind tractor of the mentioned model, you can make a mini-tractor with such parameters as:

- clearance - 21 cm;

- total length - 240 cm;

- total width - 90 cm;

- the total weight is about 400 kg.

The conversion kit itself weighs approximately 90 kg.

If we are talking about alteration of Agro walk-behind tractors, it is imperative to remember that their axle shaft is too weak. She may not be able to cope with the increased load. You will definitely have to put on a homemade device another, more powerful part of the same kind.

Regardless of the brand chosen and the features of the future operation of the tractor, it is imperative to draw up a detailed drawing, which reflects the attachment of the shovel and other auxiliary components.

Drawing up drawings on your own is not just drawing some graceful picture, but you will also have to think over all the subtleties and carry out calculations.

The supporting structure is made of steel profiles or pipes. The thickness of the metal must be large. The heavier the steel elements are used, the better the result will be.

To connect the parts of the frame, choose one of the following options:

- welding;

- attachment to bolts and nuts;

- mixed approach.

Strengthening is carried out by means of a transverse beam. Such an improvised stiffener is recommended for use on all-wheel drive vehicles subject to significant loads.

During assembly, it is worthwhile to provide a mechanism with which the attachments will be attached to the frame.

If you plan to use a mini-tractor as a tractor, a towbar is mounted behind.

The front wheels are made using ready-made hubs, attached to a tube of the same width as the axle. When this stage of work is completed, a hole is drilled in the center, and then the pipe is attached to the frame. To connect the steering rods to it, you need to use a worm gear, which will allow you to control the turns of the wheels.

After the gearbox, it is only the turn of the steering wheel assembly. Next, you need to tackle the rear axle, which is installed using a bushing with bearings. This bushing is used to install the pulley. Through it, the energy generated by the motor is supplied to the axle.

The rear wheels, depending on personal preferences, are taken from cars or from the delivery set of the walk-behind tractor. It is recommended that they have a diameter of at least 30 cm and not more than 35 cm.

This value makes it possible to guarantee both stability of movement and high maneuverability.

In most cases, motors are installed in front of the frame or even in front of it. This solution helps to balance the parts of the mini-tractor structure.

Experts advise using movable fastening systems. They make it easier and more convenient to tighten the belts that transmit force to the rear axle. Therefore, the installation of a more complex mount is fully justified.

As soon as the main part of the structure is assembled, the brake system and the hydraulic line are connected. It is worth noting that when using mini-tractors on public roads or in the dark, equipping cars with headlights and side lights plays an important role. But special sun visors will not play a special role. Mount them or not - everyone decides on their own.

It is worth noting that such a serious alteration is not always made. They usually resort to it to make a mini-tractor from a diesel walk-behind tractor. It is already quite powerful in design to withstand all the load that is created. And here if there is not enough power, use an additional trailer adapter... It is made on the basis of a uniaxial frame.

Often the suspension is a disassembled motorcycle sidecar.

Axles are advised to be made from corners with a section of 4x4 cm.It is easy to weld wheel bushings to such corners. The location of the bushings should be determined in advance, thinking first of all about the reliability of the fastening.

Having put on the wheels, they begin to engage in fasteners. Having placed the walk-behind tractor near the axis, they measure the distances for cutting the pipe.It is better to supplement the attachment point with an auxiliary frame no larger than 30x30 cm.

From "Agro"

If you have just such a walk-behind tractor, the following elements will be needed to refine it:

- steering wheel (removed from an old car is useful);

- 2 running wheels;

- armchair;

- metal profile;

- sheets of steel.

To perform exclusively field work, you can do with a solid frame. But if you plan to ride a mini-tractor, it is recommended to make a breakable frame.

A very crucial moment is the choice of the location of the engine. By placing it in front, you can increase the maneuverability of the apparatus. However, the pressure on the wheels will increase, and problems with the transmission are not excluded. Since in most cases mini-tractors are used for driving, they are mainly made with break frames. The assembly of such frames is made from profiles and sheets (or pipes). As in other cases, it is recommended to make the main part of the tractor heavier.

The wheel hubs are attached through a hole drilled in the front frame.

The steering column is installed only after the worm gear has been installed. To install the rear axle, bearings are used that are pre-pressed into the bushings. A pulley is attached to the axle itself. When all this is done, and in addition to the wheels, mount the motor.

Of course, it will be useful to supplement it with headlights, side lights, as well as a special painting.

From "Salut"

Among the products of this brand, it is easiest to remake the Salyut-100 walk-behind tractors. But with other models, the work is a little more difficult. Even if you plan to transfer the device to a tracked drive, you should carefully study the factory drawings and kinematic diagram.

It is better for inexperienced and inexperienced craftsmen to abandon the manufacture of complex fractures. It is not recommended to make a narrow driven axle. If its width is less than 1 m, there is a high risk of overturning the mini-tractor on a sharp turn.

An important part of the work is to increase the width of the wheelbase. By purchasing ready-made bushings, you can achieve it without turning. In the absence of differentials, rotary blocking extensions are used.

The choice of the type of chassis and drive is always at the discretion of the owners of the equipment. When the frame is prepared, the side members of the transverse and longitudinal stroke are cut using the angle grinder.

Their subsequent connection is possible both on bolts and using a welding machine. Ideally, a combined option is used, since it allows you to achieve the highest strength of the joints.

On "Salutes" it is recommended to put a fracture, assembled from a pair of semi-frames connected by hinges.

This design is characterized by increased driving performance. Wheels originally intended for a walk-behind tractor are put on the rear axle, and specially selected rubber with a well-traced tread is put on the front axle.

If "Salut" was altered with the installation of a motor of the same power as in the beginning, you will get a tractor capable of performing any type of field work on an area of up to 2-3 hectares. Accordingly, if a larger area is to be cultivated, the total engine power must also increase.

Judging by the reviews, a good result is obtained by using parts from ready-made kits together with parts of fire pumps... Such a structure can easily climb uphill even with a significant load. Some amateur craftsmen use wheels from SUVs - it turns out just as well.

From "Oka"

To convert such a walk-behind tractor into a mini-tractor, you need to use two-speed gearboxes with a reverse. And also you can not do without chain reducers. Equipping with a prefabricated frame, initially divided into 2 parts, is allowed.

Most often, the prepared devices have a 4x4 wheel arrangement (with all-wheel drive). The motor itself is placed in the front and covered with a standard hood.

From Shtenli

First of all, you should remove all unnecessary from the walk-behind tractor itself. For the assembly itself, you will need a gearbox, a box and a motor.No more components from the original walk-behind tractor (if there is a frame) are needed.

The drive must be done using a shaft with two gears. The upper platform also includes a support bearing.

The large backlash that occurs when installing the hexagon is eliminated by the addition of band saw blades. If a blade from a metal saw is used, it is necessary to cut the teeth with a grinder.

The steering column is taken from the Zhiguli, and the steering knuckles can be taken from the Oka. The rear axle is assembled on 120 channels.

In addition to the Shtenli DIY mini tractor, you can make a front adapter.

From the "Ural"

In the course of this conversion, a steering gear from a VAZ 2106 is used. The steering knuckles and crosses can be supplied from old trucks such as the GAZ52. It is recommended to use hubs from any VAZ model... The wheels remain the same as on the original walk-behind tractor. Pulleys are also left from the "Ural", but if they are not there, they order a special replacement with a diameter of 26 cm.

Everything is assembled in such a way that when you press the pedal, the belt is tightened along the outer diameter.

The use of a three-point linkage is optional. Do not try to make gear levers as long as possible. Better to add extra leverage in free space... Such a solution, however, would be a purely temporary solution. Floating mode is provided by a chain.

Recommendations

Judging by the experience of operating home-made mini-tractors, the best motor option is a four-cylinder water-cooled diesel engine with a capacity of 30 to 40 hp. with. This power is enough to process even the most difficult land on large lands. Cardan shafts can be taken from any machine.

In order to simplify the work to the limit, it is recommended not to make the front axles with your own hands, but to take them ready-made from cars.

For maximum cross-country ability, large wheels are used, while the deterioration in handling is compensated by the addition of a power steering.

The best hydraulic parts are removed from old (decommissioned due to wear and tear) agricultural machinery.

It is recommended to put tires with good lugs on the mini-tractor.

Accelerators and hinged mechanisms, regardless of the modification being created, operate under manual control. Steering racks and mechanisms connected to pedals are most often taken from VAZ cars.

Do not underestimate the importance of installing the driver's seat, sometimes a few centimeters shift makes a big difference.

For information on how to make a mini tractor with your own hands, see the next video.

The comment was sent successfully.