Homemade walk-behind tractors: features and assembly instructions

To cultivate a land plot requires a huge amount of physical effort. Some farmers enjoy physical labor, so they are quite satisfied with the elementary tools in their work. But most summer residents use walk-behind tractors for plowing acres in their personal plot, which are often assembled with their own hands.

Design features

A homemade walk-behind tractor is used most often to perform simple, but laborious work:

- plowing a land plot;

- hilling plantings;

- mowing grass or tops;

- application of organic fertilizers.

You can upgrade any walk-behind tractor with a ZiD engine or some other, make it on large wheels, with a belt drive.

Often, craftsmen prefer to reassemble such units using old spare parts from such mechanical devices:

- chainsaws of the "Friendship" type;

- motor scooter;

- motorcycle;

- washing machine.

An electric motor may also be required in such a technique, for example, to create air cooling, so a motor from a vacuum cleaner or a small refrigerator can also come in handy.

If a person owns a tool, understands the device of technology, then making a walk-behind tractor is not difficult. In terms of material costs, this may cost the minimum amount, while prices for a good unit start at $ 300. If everything is done correctly, a new self-made device can be in no way inferior in reliability and performance to imported models of the "Cayman" walk-behind tractor.

Often, masters use old units from the Druzhba saw as engines. At the same time, the walk-behind tractor is easy to operate, even a non-professional or a minor can work with it. The power plant is capable of withstanding significant loads without stalling even at low speeds.

This indicator is important for the following work:

- plowing;

- harrowing;

- harvesting.

Even branded walk-behind tractors not all can perform such work.

Advantages and disadvantages

The advantage of a home-made walk-behind tractor is that it can be made, focusing on the needs that exist in this farm. For example, a practical unit must do the bulk of work on plowing and harrowing. In accordance with these "requests", the frame is made of the required size, the engine is adjusted so that it runs at low revs. It is necessary to tidy up the assembly that secures the attachment.

One of the shortcomings is that it is not always possible to perfectly fit all the blocks taken from different mechanisms to each other with your own hands.

In order for all the units to work in a complex, one must be fluent in many engineering professions, have a fair amount of practical experience.

How to do it?

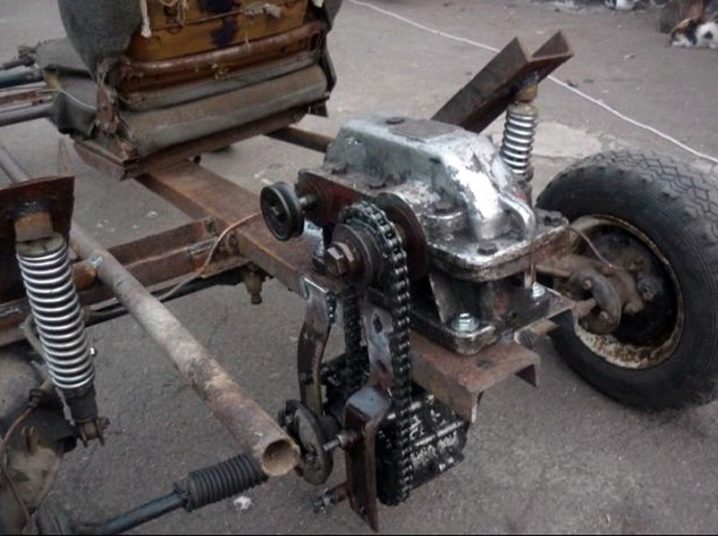

The example that will be given below (master V. Arkhipov) will be a good illustration of how you can assemble an all-wheel drive walk-behind tractor at home with your own hands. Cables can be taken from "Ant", ZAZ, scooter, rear axle - from VAZ, box - from "Zhiguli"... The main body is cooked from pipes with a diameter of 40-45 mm. Modular hinges are installed as rods, which will be a reliable "connecting link" between the power plant, plow and steering wheel.

Another tube is welded onto the supporting frame, which ends with an axis. Thus, the tension of the cables going to the box is challenged. The tension is realized using a moving lever.

This unit has a number of advantages. First of all, mention should be made of the hinge block. The non-dynamic rigid connection (which is found on many models) makes the mechanism difficult to operate. Swivel joint is more productive - you can change the direction of movement during plowing, while the plow can remain in the furrow.

This topic is quite relevant, because because of the resistance of the soil, the car is constantly "leading" in different directions. It often takes additional attention and effort to keep the mechanism on course.

The axis of the device is aligned along the vector of translational motion. During plowing, the entire block is slightly "turned". Moreover, the optimal angle can actually be corrected with the hinge rods.

The plowing depth can be maintained automatically. It should be said that the frame is equipped with a field board. It regulates the force that is responsible for sinking the plow into the ground, especially when it is burrowing. If it protrudes from the ground at too high an angle, then the angle of attack increases accordingly, then the unit again enters the soil by a predetermined amount.

The future walk-behind tractor is equipped with a supporting frame and wheels, which can be made of metal, they will have good adhesion to any ground. To reliably "couple" the frame with the suspension, usually two bent tubes are used, between which the fuel tank is mounted.

To properly equip the engine, a bracket is used, at the end of which there is a steel axle (its length is 15 cm).

A bracket is welded to the frame itself, an engine is placed on the axis. The entire power unit is held together by arcs. Upon completion, another shaft is placed, control cables and chains are pulled.

Such a unit can perform many different jobs and be a versatile device. To do this, simply change the spare parts intended for the plow for the elements necessary for the functioning of the cultivator.

While driving, the machine deepens the furrow in the soil and at the same time places potato tubers there. To "close" the tubers, you just need to use the walk-behind tractor for this a second time... The algorithm for hilling plants is exactly the same.

The use of different dumps allows you to adjust the working width, it is also possible to “pick up” potatoes that were not harvested during the first pass. The walk-behind tractor can be used to remove snow and wet foliage, you just need to "pick up" a stiff brush.

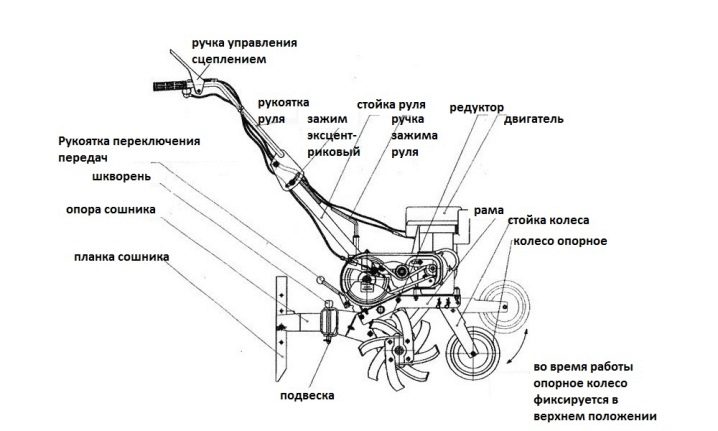

Any walk-behind tractor consists of the following units:

- engine;

- transmission;

- controls;

- reducer;

- aggregation system.

It is best to choose a two-stroke engine; a motorcycle engine from IZH-Planet is ideal for this.

Transmissions are in the following motoblocks:

- toothed (it can be found most often on tractors or tanks);

- gear-worm;

- complex (gear and worm) with an additional pulley.

The system of various controls contains:

- gear shifting;

- gasoline supply;

- brake.

The control node is a set of levers that are responsible for:

- speed switching;

- the flow of fuel into the engine;

- brake.

The mechanism must be equipped with an aggregation device that provides a reliable hitch with attached equipment.

Required materials and tools

To assemble a walk-behind tractor yourself, you will need certain practical skills, as well as some engineering knowledge.

From the tool you will need:

- welding machine;

- grinder;

- drill;

- keys;

- screwdrivers.

Consumables are also required:

- nuts:

- bolts;

- counter washers.

As for the materials, you will need:

- pipes;

- corners;

- brackets;

- metal sheet 5 mm thick.

Step-by-step instruction

Correct assembly begins with the study of the drawings and the layout of the frame, which consists of pipes with a diameter of 45 mm. The control unit is attached to the rear of the frame. In front will be the transmission and battery, which will be mounted on a small metal platform.

The motor is attached to corners that are welded to the frame. A cross member is welded between the corners, it will be a "support" for the engine. Holes are drilled in the corners for fastening the nodes with bolts.

Correct installation of the gear unit is essential. It is usually placed between the wheel and the power plant.

Often, part of the energy of the rotating element is transformed with the help of a gearbox to attachments. The engine is cooled using an air flow, for this, an electric motor is additionally installed, which is powered by 12 volts.

The wheels have a diameter of 12 cm. Chains are sometimes put on the wheels for better grip.

The muffler can be used from a moped or scooter, you can also make it yourself. An important unit is a small adapter that connects the pipe to the muffler. It must be made by a turner or locksmith.

The fuel tank can be made from an ordinary canister. It is enough to make a hole in it and solder the hose (you can use cold welding). It is not difficult to get all the materials at hand, they are inexpensive, but some units will need to be ground, that is, they must be ordered from qualified specialists.

The welding machine can be rented and welding can also be done by yourself.

How to upgrade?

The functions of the walk-behind tractor can be significantly expanded if the attachments are correctly attached to the additional equipment.

Most often, they put on medium-power walk-behind tractors such devices:

- cutters;

- plow;

- mowers;

- hiller;

- rake;

- trailer;

- brush for cleaning snow and debris.

You will learn how to make a homemade walk-behind tractor with your own hands in the next video.

The comment was sent successfully.