How to run in a walk-behind tractor correctly?

Motoblocks are a very valuable technique in the personal household. It must be handled skillfully and responsibly. However, mistakes can be made even at the very beginning of operation. You will learn how to properly run a new walk-behind tractor in this article.

Beginning of work

Without running in the walk-behind tractor, it is absolutely impossible to start using it fully. Those who do otherwise are almost inevitably faced with a host of deformations and breakdowns. Also, the block may work unstable if it is not first run in. And worst of all, a premature failure of the device is likely. This is a sure way to costly repairs or even to replace a problematic device.

It is important to understand that preparation for work is no less important than the operation itself. If they try to run in a walk-behind tractor in violation of the rules, it is illiterate, then it breaks down in almost 100% of cases. Then the necessary repairs are even more expensive. It is important to take into account that if a major overhaul was carried out, the machine and its engine will have to be run in again. Without this, there is nothing to think about that the walk-behind tractor will work properly for a long time.

Features of the procedure

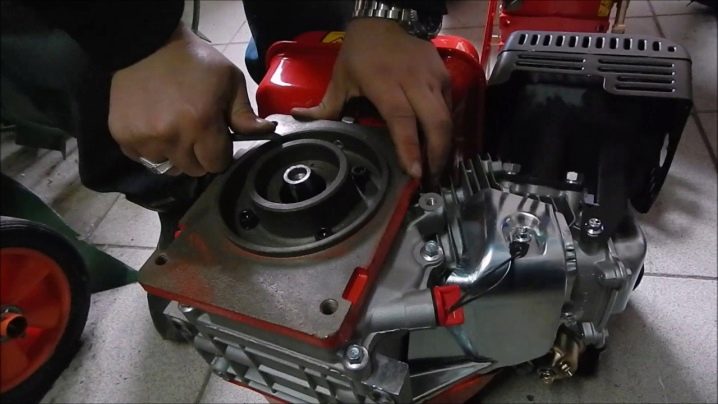

The first step is to scrupulously check every fastener, every bolt. The tank is 100% filled with gasoline or other necessary fuel, engine oil. Be sure to take care of the preparation of the coolant in the required amount. Running in does not just mean "grinding" the engine parts to each other, "triggering" them together. You also need to carefully check the serviceability of the brakes and steering gears.

It is impossible to run in a walk-behind tractor normally if the steering wheel is not set according to the rules. After running-in, every detail should be inspected immediately. This takes time, so it is worth planning all the work carefully so that nothing interferes with the process. The technical inspection includes:

study of the condition of each oil seal and bearing;

rubbing them with oil;

immediate replacement of damaged and deformed parts;

checking the springs of the forks and control elements.

What else do you need to know?

Apply lubricant and fill the coolant yourself. You cannot trust store employees and gardening equipment suppliers. If they make some mistake, the consequences will be irreparable. When running in both completely new and overhauled equipment, starting without oil and coolant filling is guaranteed to "kill" the most reliable motors. As always, you cannot do without reading the instructions - they describe such subtleties that are unlikely to be found in other sources.

The main points that a farmer should be interested in are the time of running-in manipulations and the permissible load of the walk-behind tractor with them... Typically, the cultivator is loaded at 50% of the maximum value. That is, if it is designed for plowing virgin soil 50 cm deep (this is only possible for the most powerful models), it is not allowed to plow more than 30 cm during running in.To reduce the cost of purchasing spare parts for run-in motoblocks and find them faster, it is immediately choose devices of well-known brands with a developed service network. The load limitation applies, of course, to the maximum weight of the transported load.

Checking the presence of oil is not only done visually. It is much safer to unscrew the screw or remove the cover (depending on the model) and see if the technical fluid flows out. If it does not flow, then you need to fill the tank full.After completing the preparation, the engine is started. They make him work at half load for a while. For most modifications, this time is 8 hours.

Despite the formal end of the running-in, it is possible to fully load a personal cultivator only after 20 or even 30 hours of operation. It is important to keep this in mind. An equally significant point is that the most competent running-in will give a good result only under the condition of a smooth transition to the impeccable operation of the walk-behind tractor. The same oil level in the engine and gearbox should be assessed before any start-up, even if it is 10-15 minutes to work. It is also worth carefully monitoring the amount of fuel in the tanks. Saving on the quality of fuel and lubricants is unacceptable - it quickly turns into even greater losses.

When the engine is running, it should first run at medium speed. Only after warming up, you can begin to work fully. However, even in normal operation after running-in, loading at 100% without a compelling need is undesirable. If it is possible to transport a consignment in 2 or 3 receptions, this should be done. Experienced people have a similar approach to plowing land, harvesting, etc.

Approach different models

You can run in the Neva and the Plowman in 20 hours. For a motor-block "Oka" with a Chinese engine, this period is 30 hours. The Zirka blocks are the most capricious - they are run in for at least 50 hours. During this procedure, it is not recommended to immerse the plow or cutter installed on the "Zirka" more than 10 cm into the ground. It is important to remember: all walk-behind tractors can only be lubricated with impeccably clean oil, carefully making sure that it does not get dirty during filling.

When a walk-behind tractor is run in with a Briggs & Stratton engine, it is imperative to change the engine oil every 5-8 hours. If a Honda engine is installed, do not allow long idle operation. Otherwise, the accumulation of oil in the crankcase will deprive the lubricant of its useful properties. Subaru requires:

monitor the condition of air filters;

evaluate the quality of spark plugs and fuel lines;

avoid heavy contamination of the cylinder ribs.

For information on how to properly run a walk-behind tractor, see the video below.

The comment was sent successfully.