Reducers of the "Neva" walk-behind tractor: device and maintenance

Motoblocks of various sizes and companies (including those from TM "Neva") have become an indispensable assistant for farmers and owners of large summer cottages. The reliability and efficiency of this device depends on its technical condition and proper care. Therefore, it is worth considering the basic principles of servicing the gearboxes of the Neva walk-behind tractor.

Appointment

The possibilities of regulating the speed of rotation of the shaft of an internal combustion engine are limited by the available operating modes, therefore, in motor equipment (from motoblocks to cars), devices are traditionally used that make it possible to change the speed of rotation transmitted from the engine to certain structural elements.

If a gearbox is used in cars for this purpose, then gearboxes are traditionally installed on Neva walk-behind tractors, which make it possible to control the rotation speed, torque and direction of movement. It is to this element that the wheels of the device are connected, and various attachments that require connection to the engine (for example, cultivator cutters, mower blades, brooms, and so on).

How does it work?

Despite the fact that the St. Petersburg plant "Krasny Oktyabr" produces a wide range of motor-blocks "Neva", differing in power and configuration, the gearbox in all these devices is arranged according to a single general scheme. According to the principle of operation, the gearbox used is of the type of gear-chain, where the change in rotation speed is carried out due to the interaction of a system of gears of different diameters and with a different number of teeth, which are either in direct contact with each other or are connected by a chain drive.

This design combines the device used on motoblocks with a bicycle gear shifting mechanism - slowing down the rotation is achieved by transferring the transmitting chain to a gear with a large diameter. The only difference is that in the gearbox, in addition to the gears located on the same axis, separate gear links are also used, which make it possible to vary the speed and direction of rotation over a wider range, as well as to transfer rotation simultaneously to the wheels of the walk-behind tractor and to the equipment used on it ...

The entire system of chains, shafts and gears of gearboxes of motor-blocks "Neva" is placed inside a strong sealed case made of aluminum. Lubrication of rotating parts is carried out by filling the product with oil (this principle of structure is called "oil bath").

An important design feature of the gearboxes used on Neva walk-behind tractors is the presence of a mechanism for disengaging the wheel axle shafts, which allows, if desired, to transfer torque to only one of the 2 wheels of the device. This makes maneuvering much easier.

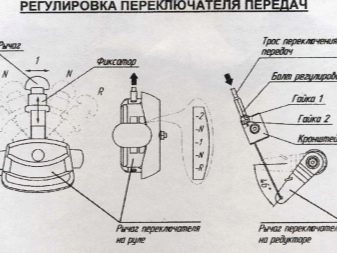

The gear shift lever, as well as other elements for controlling the gearbox, are brought out, which greatly facilitates its adjustment. There are 5 positions in total. When the lever is pressed, the fork connected to it disengages the rotation transmitting clutch from the gears. When shifting the lever, the fork moves the clutch to the desired position.When you release the lever, the clutch engages with the desired gear system and the fork returns to its home position. In standard operation, rotation is transmitted through a gear located near the input shaft of the device.

Connecting the drive to the right axle leads to a slowdown of the walk-behind tractor. "Drowning" of the shift knob causes the clutch to shift to the left, larger gear, which results in a downshift. This is useful when you need to develop more torque at a lower travel speed.

Finally, extending the lever all the way to the end results in an overdrive, allowing for a higher travel speed.

The dimensions of the gearboxes used on the products of the Krasny Oktyabr plant are 23 × 30 × 61 cm, and their weight without oil does not exceed 18 kg. The volume of the oil sump used to fill the device with oil is 2.2 liters.

The diameter of the shaft transmitting rotation from the device to the wheels is 30 mm.

A significant disadvantage of the design used in the gearboxes of the Neva walk-behind tractors is the fact that in order to shift gears it is necessary to turn off the engine and wait until the rotation of the device pulley has stopped completely. Shifting gears "hot" can lead to seizure, chain breakage or breakage of gears.

Basic rules for performing work

Any work on disassembly and assembly of the gearbox, as well as on its maintenance must be carried out at a pre-prepared workplace with all the necessary tools. It is imperative to ensure the cleanliness of the workplace, which will eliminate the ingress of dust, dirt and debris into the mechanism... It is advisable to carry out all work with clean work gloves, which will provide both protection for hands from injury and dirt, and protection of gearbox components from unwanted debris and dust.

Keep a close eye on the condition of the tool you are using - there should be no noticeable damage, especially cracks... Failure to do so will result in dangerous injury.

Drain the oil from the gearbox before disassembling it. After that, you need to thoroughly clean all parts of the device from possible contamination.

After repairing and assembling the gearbox, be sure to fill it with fresh oil before operating it.

Typical breakdowns and their repair

The most frequent breakdowns of the device are as follows.

- Oil flow through the output shaft. To eliminate this problem, it is necessary to change the oil seals installed in the gearbox. To replace them, you need to purchase new ones, dismantle the ones installed in the gearbox with a screwdriver, and then install new oil seals in their place. This will help strengthen the walk-behind tractor, the power of which is reduced due to constant oil leaks from the gearbox.

- If there is a shift shaft leakage, you may have added too much grease to the gearbox. Therefore, it will be enough to drain the excess oil and check if this helped in fixing the problem. If leaks continue, replacing the oil seals will help.

- Open circuit, which leads either to jamming, or to the impossibility of operating the device in individual gears. For repair, you need to replace the broken chain with a new one.

- If the gearbox does not transmit torque in any of the installed gears, it is most likely that one of the gears has broken. After disassembly, you need to find the broken sprocket and replace it with a new one.

- If the gears do not shift, you need to check the condition of the fork, bushing and thread of the gear knob, and then replace the damaged element.

To expand the capabilities of the walk-behind tractor, its modernization will help by installing a full-fledged gearbox, for example, from a VAZ car, instead of a gearbox.

How to choose spare parts?

If you want your walk-behind tractor to work stably without the need for constant repairs, be sure to purchase only new spare parts from authorized dealers. It is best to purchase spare parts for gearboxes in certified service centers and partner stores of the Krasny Oktyabr plant.

Pay particular attention to the type of oil you are going to add to the gearbox.

For devices used on Neva walk-behind tractors, the following brands of transmission oil are best suited:

- TEP-15;

- TM-5;

- SAE90 API GI-2;

- SAE90 API GI-5.

To learn how to change the gear chain of the "Neva" walk-behind tractor, see the video below.

The comment was sent successfully.