Hydro filter for barbecue: what is it?

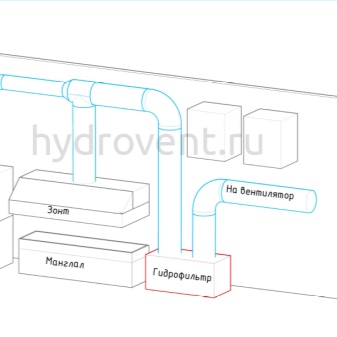

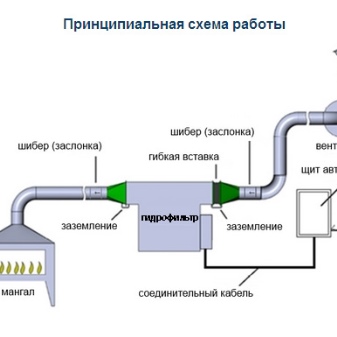

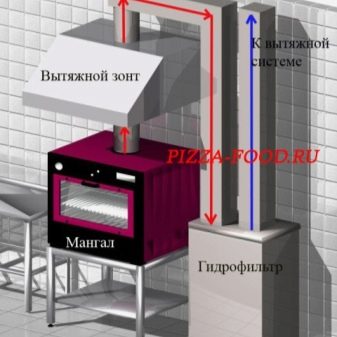

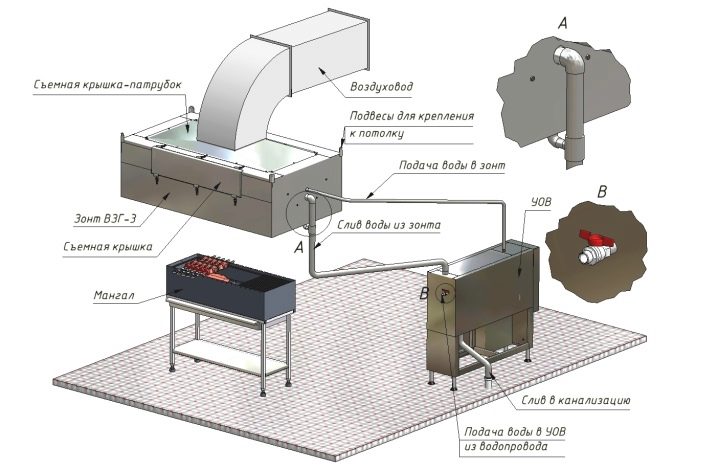

A brazier located indoors is usually supplemented with a special chimney system. It consists of a chimney and a hood. In addition, one of the components of such a system is a hydrofilter.

Peculiarities

Special hydraulic filters are usually installed in barbecues of restaurants, cafes or bars. It is in such establishments that meat is often cooked over charcoal, and a filter is necessary for high-quality ventilation. Such a system is also useful for other premises where, for example, barbecue is prepared on weekends.

The main task of water filters is considered to purify the air from:

- sparks;

- fat;

- products that form a solid form of incompletely combusted fuel;

- the smallest dispersed particles.

Sparks and grease are the most harmful elements for a chimney.

A high-quality hydraulic filter provides:

- complete elimination of soot;

- elimination of fat by 90%;

- lowering the temperature of carbon monoxide to 40º;

- full extinguishment of sparks.

Hydrofilters are made by specialized production workshops that have certain certificates. An important condition is considered to be a guarantee of fire safety, which should be provided by a hydraulic filter at the facility. Almost all manufacturers try to produce highly efficient devices, but, unfortunately, not every enterprise succeeds. You can make such a device with your own hands, but you can install a homemade water filter only with the consent of the relevant authorities.

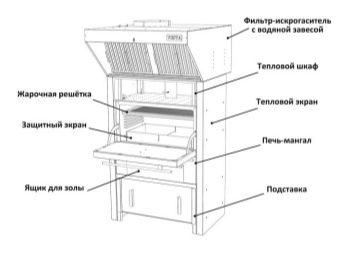

Design

Water filters for barbecue can have various elements located inside the body. The list of components depends on the manufacturer. And yet, most of the models are similar in structure.

Typically, the design of a hydrofilter consists of:

- welded geometric body made of fire-resistant stainless steel;

- water spray systems;

- mesh spark suppression filter;

- labyrinth grease filtration (usually these products are made of stainless metals, which allows you to increase the operating period and make the filter work of the highest quality);

- systems for separating smoke from liquid;

- valve supplying ordinary water;

- pressure sensors;

- couplings designed to remove contaminated fluid.

A complete system with a hydro filter can be installed on the chimney itself, while the latter can be of any section (round or square). Manufacturers are trying to take care of the comfortable connection of the hydraulic filter to the chimneys. Often this type of care can manifest itself in the form of equipping the device with special flange connections, which are made from stainless steel. In the meantime, a 3-millimeter-thick corner is taken as the starting material.

The electric drive is specially adjusted so that it starts to work together with the ventilation fan. At the same time, the water supply valve opens.

There are two main types of devices:

- labyrinthine;

- reticulate.

Hydrofilters are also distinguished:

- vertical;

- horizontal;

- Z-shaped;

- U-shaped;

- L-shaped;

Mesh type spark arresters are small in size. This nuance is an important advantage over labyrinth filters. Accordingly, the latter are distinguished by the largest dimensions, which is considered a negative quality for this type of device.

Operating principle

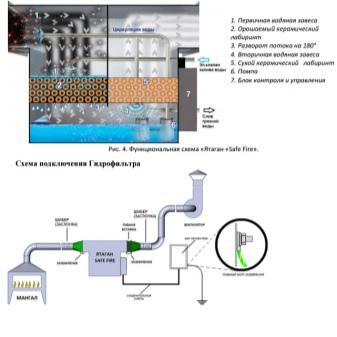

Hydrofilters usually receive air heated to 90-180º.Initially, the air mass accumulates in the chimney hood, while part of it begins to pass through the chimney. When smoke enters, various processes start.

Initially, the heated air mass is directed through the mixing chamber. Water starts to flow at a pressure of 2 bar. Then water begins to flow through the full cone type of nozzles. This is how water is sprayed through the mixing chamber. As a result, the hot air stream, being irrigated, begins to be humidified and becomes cooler.

It is also necessary to mention that the pressure gauge "watches over" the pressure of the supplied water. In addition, there is a reducer that begins to influence the pressure according to the situation.

Then the air enters the section, which is filled with a mesh spark suppression filter. The elimination of fat particles occurs when wet smoke passes through the chamber, which is filled with a grease labyrinth filter.

The process then involves the lime water steam section to suppress the smoke. Movement begins to occur in the water separator section. Separate liquid that has absorbed dirt is discharged directly through the valve. The drain takes place into the sewer system. The cooled air purified from polluting components passes further along the chimney itself or through the ventilation.

Installation

Hydrofilters are usually installed horizontally. The device is placed on the wall, on the floor, or under the ceiling itself. Dedicated fixing brackets are provided for wall mounting. If you need to install a hydraulic filter under the ceiling, you may need mounting rails and special studs. In this case, the slats are fixed horizontally. Then the hydraulic filter itself is placed on them.

For floor standing installations, a power frame must be used. On this frame, the smoke-removing device will be installed. It is better not to install water filters directly on the floor.

An important feature of the functioning of the water filter is the reduction of thrust, that is, the creation of resistance for the fan. This resistance is usually 300 Pa. Accordingly, when installing hydrofilter systems, it is necessary to pay attention to supplying the room with powerful fans.

How to choose

When choosing a hydraulic filter, you should focus on the budget that you are ready to allocate for the purchase, as well as the operating conditions of the kitchen equipment. It is worth deciding what device capabilities you need.

The cost of the filter will depend on its functionality. Some models provide full automation of the process. The start-up is carried out by the air flow, the contaminated water from the filter is drained by itself at the end of work or after a set time. The filter is also filled with water automatically when the level sensor gives a signal. You can observe the operation of the water filter by the installed sound or light indication.

The block controls:

- temperature of incoming and outgoing air streams;

- water temperature and level;

- operation of the pump and valves responsible for draining and filling with water.

In addition, the hydraulic filter, exhaust hood or supply ventilation can be turned off manually. For economical operation, the systems smoothly adjust the air flow rate.

Exploitation

The quality of operation and durability of the device will depend on the correct use of the filter.

There is a list of required maintenance conditions:

- water replacement and inspection for leaks should be carried out once a day;

- rinsing the filter itself (as well as rinsing the level sensor) should be carried out as soon as it gets dirty, but at least once a month.

Only when the above operations are performed will all the units of the hydraulic filter work for a long time and efficiently. It is worth remembering that maintenance and flushing are performed only after disconnecting the power supply.

In conclusion, it should be said that the water filter is a very useful device. In addition to ensuring fire safety, it will keep the indoor air clean. Clean and fresh air, in turn, will create a comfortable environment conducive to relaxation and a pleasant meal.

See the following video for testing the hydrofilter.

The comment was sent successfully.