The subtleties of installing a fence made of corrugated board with a foundation

Decking is an affordable material for various structures erected in the country or in the courtyard of a private house. Roofs, parapets, walls of buildings are sheathed with it, supporting structures are strengthened, all kinds of fences are erected. A budgetary and reliable fence made of a professional sheet can serve for many years if it is correctly installed. The foundation in this case is a key factor in the reliability of the structure. The rest of the construction of the fence is not difficult, but it takes some effort.

How to Build: Design Options and Diagramming

Fences made of corrugated board can be made in any modifications. Some structures do not include a foundation, but they are easy to install and inexpensive.

Profiled sheet fences can be of different types.

- Solid fence. It differs in that it does not need a foundation, metal pipes and a frame welded onto them are sufficiently firmly dug into the ground. The sheets are overlapped with each other with a solid fence, such a fence can reach a height of 3 m (for the maximum width of the sheet). Sheets of material are attached to the frame and pillars using special self-tapping screws, protected by a polymer layer from corrosion.

- Sectional hedge. It differs from the previous variety in the presence of a columnar foundation, which is poured pointwise under each support, and pillars made of brick, tuff block or natural stone. This installation method gives the fence a complete classic look.

- Modular fencing. It is made from ready-made modules, made in the factory. It is installed quite quickly and relatively easy. The fence has an impressive appearance, is compact, fireproof, if necessary, it can be dismantled, moved to another place and installed.

- Sectional fence on a strip foundation. The concrete base is poured along the perimeter of the entire fence, pillars are installed, the profiled sheet is fastened in sections. Such a fence is stable and durable, moreover, it has an aesthetic appearance.

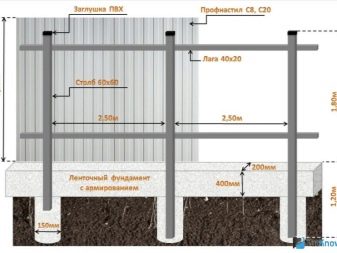

Drawing up a diagram will greatly simplify the task of construction, and also reduce the cost of building materials. When planning a sectional fence with a strip foundation, the width of the section is determined according to the width of 1, 1.5 or 2 profiled sheets.

The drawing order includes several parameters.

- The place where the fence will be erected. This parameter helps to take into account the features of the relief, the presence of plantings, buildings, access roads and the location of the gate.

- In case of an uneven area, it is important to draw on the drawing the places of the height differences of the future sections of the fence.

- Fence dimensions (height and length of sections).

- The locations of the supports.

Materials and tools

It is important to prepare everything you need before starting construction so as not to be distracted during work and not to delay the process.

Materials for a fence made of corrugated board include several components.

- Decking. When choosing, it is important to pay attention to the thickness of the metal, wave height, texture, color of the coating, the absence of a capillary groove. When planning the width of the sections, it is important to take into account the fact that the corrugated board has a high level of windage. Different manufacturers have different sizes of corrugated sheets, and the service life of a galvanized sheet can be up to 30, and for a material with a polymer coating - up to 50 years.

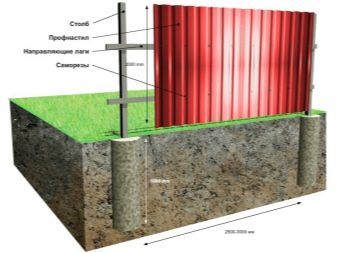

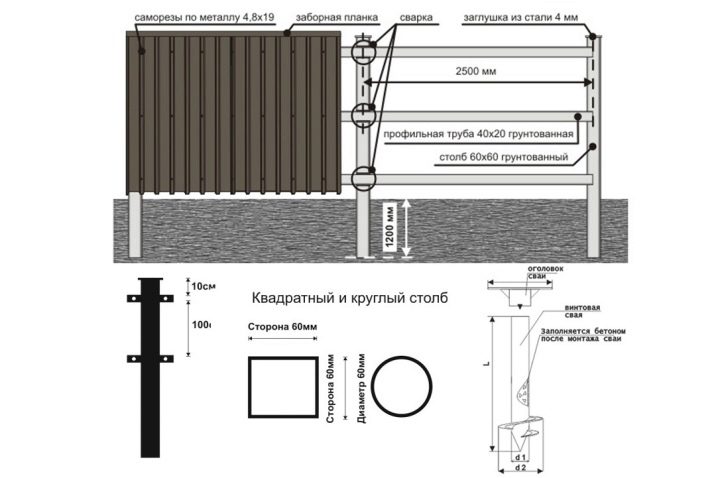

- Support pillars. Any available material (metal, stone, brick or wood) can be used for the posts. The most affordable, durable and practical option is metal (pipes). The diameter of the pipes will depend on the potential load. Pipes are used rectangular (60x40x2 mm), square (40x40x2 mm) or round with a diameter of 60-100 mm. But piles and ready-made pipes for hedges are also used. Ready-made fence supports are easy to install and durable.

- Cross bars. For logs, square pipes (40x40x2 or 20x20x2 mm) are used. Keep in mind that the width of the log should be equal to half the width of the rack. Bars made of wood as logs and racks should not be used, since wood is capable of rotting in the places of attachments. You should also not use a metal corner for a lag. Due to its small thickness, it is not able to provide the required wind resistance. Self-tapping screws with a drill for a corrugated sheet are intended for drilling material no thicker than 2.5 mm, therefore, a thick profile as supports and a lag is not used in the construction of a fence.

- Brackets and hardware. These fasteners are used to assemble the frame without welding. But you can also use bolts, screws or rivets. Self-tapping screws for corrugated board are equipped with a neoprene rubber gasket, which tightly presses the corrugated sheet without damaging it. The visible part of the screw has a polymer coating in the color of the material, which protects it from corrosion. When using rivets, it is recommended to paint the edges of the holes in the corrugated board with a special paint.

- Paint for corrugated board. It may be needed to touch up mechanical damage on the material allowed during installation, as well as for cut points. The paint consumption is small, for small needs one spray can will be enough.

- End caps for supports. If ready-made fence posts from corrugated board are not used, where this element is initially provided, special plastic pipe plugs are used so that moisture does not get inside the support post. Cut plastic bottles can be used instead of plugs.

- End plate. A covering U-shaped bar is installed on the upper part of the sections and protects the fence from moisture and corrosion, and also gives the fence an aesthetically complete look. When choosing this element, it is worth considering that its edges must be rolled, otherwise the bar will turn out to be impractical during operation and may scratch the metal during installation.

- Cement, gravel, sand. These materials are needed for the foundation or installation of supports.

- From the tool you will need a plumb line, a level, if the frame is attached without brackets, then a welding machine and electrodes.

- Mortar containers, construction mixer, shovel or drill, as well as formwork boards.

- Screwdriver, riveter (if necessary), gloves and goggles with grinder, rope.

- Primer, anti-corrosion solution for metal.

Foundation options

There are several types of filling the foundation for a fence.

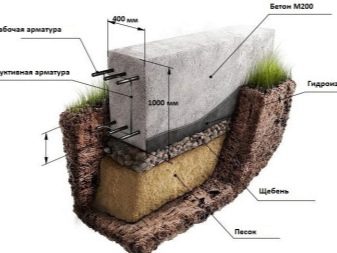

- Monolithic pouring consists in installing pillars on previously laid layers of concrete. This type of foundation is relevant for swampy soils and heavy structures. Can be used for outbuildings to the house.

- Pillar filling is used at the installation site of the fence supports. The pillars are dug deep into the soil and filled with cement mortar.

- The stone foundation does not go deep into the ground. The base is made of massive boulders, reinforcement and cement in the form of a "belt" up to 1 m high. The fence itself is mounted directly above the base. This type of foundation is not used for lightweight corrugated boarding.

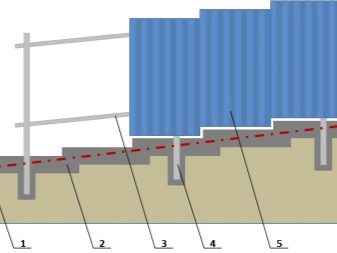

- A tape or tape-and-pillar base encircles the site around the entire perimeter, deepens into the ground by 30 - 40 cm, and is made of cement-sand mortar. The difference between a strip-and-column foundation from a strip foundation is the presence of recesses with support pillars.

The last type of foundation in a combination of price - quality has no competitors.

Base device

As an example, detailed instructions for pouring a strip foundation for a fence made of corrugated board will be described below.

The stages of work include several sequential operations.

- Markup. In place of future supports, pegs are hammered along the entire perimeter of the site and a string is pulled. It is imperative to fix the rope at all turning points of the future fence, as well as in the place of wickets and gates.

- A ditch is dug along the marking line. Its depth should not reach more than 35 cm. In the places where the posts are installed, the ditch deepens to 90 cm, depending on the soil. The width of the trench must be at least 40 cm.

- Pillars and fittings. Pillars are installed in the recesses for the supports, the height of which, taking into account the underground part, should be at least 2.5 m. The pillars are installed exactly using a level and a plumb line, the recesses are filled with broken brick, gravel and stones. The bottom of the trench is covered with a 5 cm layer of gravel, a layer of reinforcement is laid with pins protruding 8 cm above the ground (the fence itself will subsequently be attached to them). It is imperative to reinforce the foundation so that the structure does not crack soon after the completion of construction work.

- The formwork is installed inside the trench on a gravel bed with planks and fiberboard. The boards should protrude 20 cm above the ground level. The formwork is fixed inside the ditch with rubble and stones.

- Pouring with concrete. The underground grout should be composed of cement, sand and gravel. First, it is this part that is poured, after setting, the rest of the solution is poured, consisting of cement and sand. This method of filling will help to avoid the formation of internal voids in the base under the fence.

In order to properly fill the foundation for a corrugated sheet fence, it is important to strictly observe all stages of work and the technology of mixing the solution.

Frame installation and fence construction

Crossbars are laid between the installed pillars (in 2 rows). They can be fastened by welding or self-tapping screws. If the fence is planned with brick pillars, the posts and the basement are laid with bricks. After the frame is completely ready, the dimensions of the spans are re-measured and the corrugated board is cut. Sections are processed with sandpaper and then paint. The material is fastened along the grooves of the corrugation at a distance of 30 cm with self-tapping screws, when screwing which it is important not to overtighten them. Taking into account temperature changes, as a result of which deformations of the profiled sheet are possible, it is important to leave small gaps for the free movement of the material. This will prevent the fence sheathing from collapsing.

During the installation of corrugated board, mechanical damage can form. To avoid corrosion in these places, the damage is degreased with acetone or solvent and covered with an anti-corrosion primer, after which the paint is applied. Do-it-yourself installation of a corrugated board fence with a foundation is a reliable investment of labor and funds that will justify itself many times over. Compliance with the installation technology and the rules for handling materials guarantees a durable structure that can serve for more than a dozen years.

You will learn how to make a fence from corrugated board on a foundation in the next video.

The comment was sent successfully.