How to build a cold smoker yourself?

Smoked meat or fish is a delicious delicacy. In order to regularly pamper yourself with such a dish, you do not have to go shopping. You can cook smoked goodies right at home in a do-it-yourself smokehouse. It doesn't take long to turn your culinary dreams into reality. It is only necessary to study in detail the technology of self-production of a structure for smoking or buy a ready-made one.

Peculiarities

Before starting the construction of a smokehouse, it is necessary to familiarize yourself with some of its features.

- Smoking should be carried out at a temperature of 30-40 degrees.

- Properly cooked food can be stored even without a refrigerator for up to a year. At the same time, the taste will remain the same, and the quality will not deteriorate.

- The cold smoking process can take up to eight days. Moreover, it is divided into several stages - this is preparation, smoking itself, which lasts up to five days, then for another three days the product is in the smokehouse itself.

- It has a fairly simple scheme that can be implemented without spending a lot of effort and materials on it.

- In addition, in order for the taste of dishes to be pleasant, you need to make the fumigation process and temperature uniform. Otherwise, meat, fish or lard will be spoiled.

Types and purpose

Cooking smoked meats at home allows you to get delicious dishes, the quality of which you can be sure of. The same cannot be said about the quality of purchased dishes. The process consists of hot and cold smoking of food with smoke. The products are very diverse - these are different types of meat, and fresh bacon, and fish, and even delicious cheese. Smokehouses are also of two types: hot or cold smoked. They can be safely used for cooking in the country, at home, even on a fishing trip. But for all this, it is necessary to select equipment for household smoking.

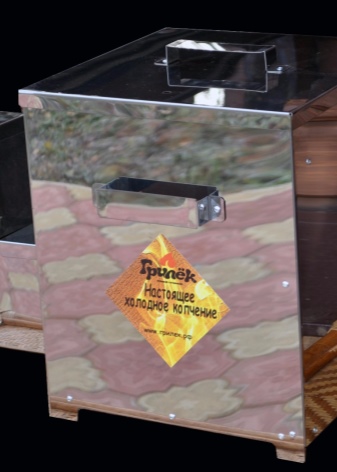

Mini smokehouse

One of the most common models is the mini-smokehouse. This design is universal, lightweight and quite convenient and easy to use. Most often, a similar device is used in hikes and in summer cottages. It has constant heating, therefore, the quality of all materials used to create it is high. It uses stainless steel, the thickness of which reaches three millimeters. In addition, it is resistant to corrosion and high temperatures.

The mini-smokehouse is heated using an electric or gas stove. In some cases, heating can even be done over a fire. However, the shelf life of products made with this device is very short. At home, they can be stored for a couple of days, but in field conditions where there is no refrigerator or cellar, the products should be consumed immediately.

There are also electric models that outwardly resemble a conventional microwave oven. However, they can only be used at home, not outdoors. In addition, this design is notable for its small volumes, so many products will not fit there.

For apartment

The designs of such smokehouses allow you to cook delicious food even in the kitchen of a small apartment. In this case, you do not need to go anywhere. However, there are several requirements for such smokehouses.

It is necessary that there is a chimney in it. For this purpose, there is a special fitting in the lid where the hose is put on. Then it is displayed in the window so that excess smoke goes to the street, and does not fill the room.If this is not done, then it will fall through the ventilation pipes into the apartments to the neighbors.

Another must-have feature is a water seal, which is a depression between the lid and the wall of the container, which is filled with water. This prevents smoke from getting here.

If there is no water seal, then a sealed cover is needed. It also keeps the smoke out.

Automatic

The source of these smokers is an electrician. They are used most often in restaurants and food industries. Their loading can be from 40 to 200 kilograms of products. The automation of such models is easy to use, therefore it does not require great skills from the person who is engaged in cooking.

All that is needed is to put small chips or wood chips, put a pallet. This is done so that excess fat and moisture flow down there. Then you can put everything that should be smoked on the wire rack. Then the program is selected and the device is connected to the network. This process may well take from half an hour to one hour of cooking.

With a tight odor trap

For outdoor cooking, a household appliance with a water seal is best suited. Its design is practically no different from a standard smokehouse. The only difference is the odor trap, the purpose of which is to prevent smoke and unpleasant odors from getting outside.

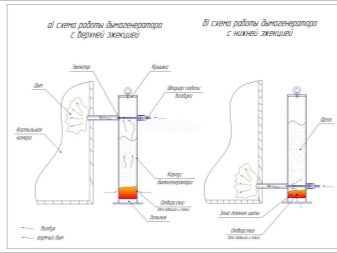

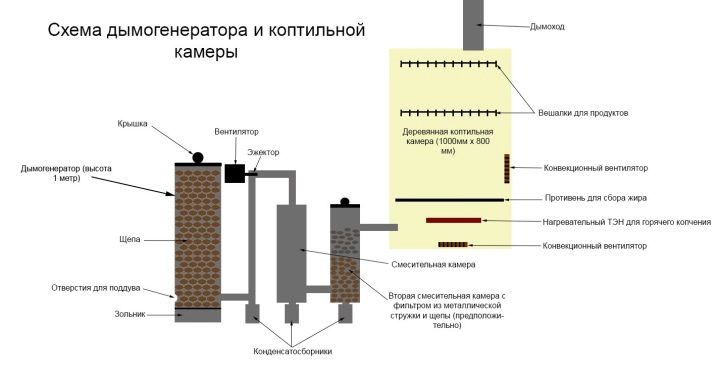

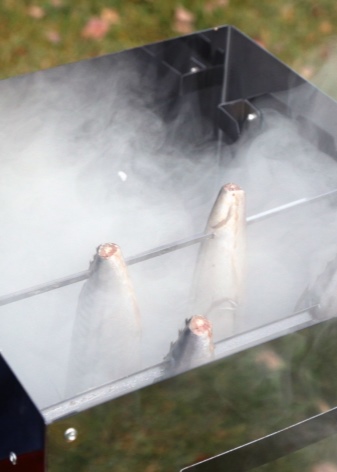

With smoke generator

The use of this device allows the smoke to enter the chamber where the product is smoked without interruption. It extends the so-called cold smoking process by a couple of days. The smoke generator has a very simple device. This is a model that connects the smoke chamber with the smoke chamber. The connection is made using pipes. Since the structure is very easy to manufacture, you can design it yourself.

With thermostat

The thermometer helps to control the desired temperature level not only in the smoking chamber itself. There is also the possibility of measuring the temperature of the food that is smoked. The thermometer itself, installed inside the smokehouse, is a probe, in the middle of which there is a tube. Its length is fifteen centimeters. At the end there is a display or indicator. The temperature for cooking a certain product is selected differently, this must be taken into account when cooking.

Electrostatic

This type of smokehouse is more suitable for use in summer cottages. They are also very often used for production workshops. They come in a variety of sizes and materials. The set of functions that are in the smokehouse system also differs.

Principle of operation

The device of a high-quality home smokehouse is quite simple. The principle of its operation is that all ingredients are processed with fragrant smoke, not exceeding a temperature of thirty-two degrees. Hot air that passes through the entire pipe is cooled and at the same time condenses, that is, harmful components leave in the sediment. After this stage, already purified smoke goes into the chamber, and the condensate goes into the ground without harming the smoked products.

This adjustment capability is a big plus. It happens due to the fact that there is slate near the furnace. By sliding it apart, unnecessary smoke can be released through the existing opening. It must be adjusted before all products are loaded into the smoking chamber. After making sure that the smoke is fragrant and not causing any harm to the environment, you can put the shutter back.

If you need to keep the smoke inside, then this can be done with a wet burlap thrown over it, which is placed on iron rods. The burlap must be moistened every couple of hours.

The loading chamber can be arranged directly in the ground by slightly lifting its top layer with the help of dead wood. On top it must be laid with fresh walnut branches.Since smoking is cold, it must be remembered that the products are not heat treated, but are cooked thanks to light smoke.

Also, the correct process of preparing products, which is divided into several stages, plays a significant role here.

First, you need to prepare a salt solution by pouring it into a container with water in a ratio of 40 grams per liter of clean water. After that, you need to mix everything thoroughly. Then you can put smoked products into the brine. If it is a small fish, then it must be kept in solution for three days, but if it is a very large fish or young pork, then the process will last four days. For tougher meats such as beef, the time is extended by one more day.

The next step is to soak the meat, which lasts from 6 to 24 hours. It all also depends on the product. Readiness is checked by pressing your finger on it. If the meat is pliable and soft, then it is ready.

After that, you can proceed to the drying of products. To do this, you need to completely drain the water from it. If there is no time, you can dab the surface with a towel. Then you need to place the product in a box or cage, wrapping it with gauze so that flies do not fly off, since the deposited larvae are not destroyed by such smoking. This process takes a couple of days. Then the blanks are placed in the smokehouse. After that, you can start smoking.

Dimensions (edit)

This cooking option, such as cold smoking, implies an affordable and uncomplicated preparation of products both in the country and on a fishing trip, and even in an apartment. However, in order for everything to turn out tasty and good, it is necessary to choose the right equipment.

For fishing or hunting, you can take a mini-smokehouse. It is very popular because it is small and easy to carry. The dimensions of the smokehouse can be 300 by 300 or 200 millimeters, while the thickness of the steel from which it is made is approximately 1.5 millimeters.

You can also take homemade brick or wood smokehouses. In this case, their sizes will be larger. Such structures can be placed only on your site. It is impossible to transfer them.

Rating of purchased models

The choice of purchased models is very diverse. There are many options for ready-made designs.

Finnish

Among the purchased models, one of the first places is occupied by the Finnish smokehouse. The device has good quality materials. Its base consists of stainless steel, which is most often used in the food industry.

It does not oxidize and does not rust. The smokehouse has a hydraulic lock, thanks to which it is completely sealed, so smoke does not enter the kitchen. Its bottom is two millimeters thick, which allows it to withstand different temperatures. This model has a lot of positive reviews, because the finished product exceeds all expectations.

"Smoke Dymych"

This smokehouse is made from cold rolled steel sheet. It includes a thirty-two liter container, a smoke generator, and a compressor.

Sawdust is placed in the smoke generator. The smoke they give off enters the smoking container through a hose. It is regulated by an electric compressor. The smoking period is from 5 to 10 hours. Such a device has many advantages: the design is compact, so it can be stored anywhere, used both in the city and in the country. The smokehouse is sold completely ready to use. The design has only positive reviews from buyers.

The advantages of homemade designs

Building a smokehouse with your own hands has many advantages. It must be installed away from the hearth, and the connection must be made using a long chimney pipe. The smoke coming out of the smokehouse is very useful in the fight against garden pests. They do not withstand a large amount of smoke in the air and die.

Homemade smokehouses can also be made from scrap materials, which does not require cash costs. You can even use an ordinary barrel for this. Better if it is new or made from a simple piece of tin pipe. If the owner wants to make the smokehouse more solid, then a material such as brick or wood is suitable for this. This design will allow you to smoke slowly and efficiently. Plus, it will serve the owner for more than one year.

Which is better?

If there is a desire to buy, and not build a smokehouse, the question immediately arises, which one is best. You should not rush into the purchase, it is better to understand all the options. When choosing a smokehouse, you should also not forget about its weight. For example, if the drawer has walls 6 millimeters thick and measures 500 x 500 x millimeters, this option may not suit you.

Also, the choice depends on how the smokehouse will be used. If for a holiday on fishing, then you need to take the option where the metal will be equal to 8 millimeters. Such a smokehouse is very light and convenient and will serve until its walls are burnt.

For home use, you can take a heavy stainless steel smokehouse, where the body will have a thickness of up to two millimeters. It will last for many years, especially if the body is reinforced with additional ribs. To cook smoked meats at home, it is imperative to buy a smokehouse that will contain a hydraulic seal to solve the problem of removing smoke. It can be easily transported from home to the dacha, while closing the pipe with improvised means.

Choice of materials

Smokehouses are made from different materials. They can be made from wood, brick, and even from an old barrel. It is worth considering in more detail the designs for their manufacture.

Brick

Outwardly, a brick smokehouse resembles a small house, which can, among other things, become an excellent decoration for a personal plot. But before purchasing materials, you need to make drawings and, based on them, buy materials. This will require:

- brick or blocks of foam concrete;

- combustion chamber or silicate brick;

- cast-iron door for her firebox;

- double-glazed windows for natural light, while the windows must be made from the north side;

- sand and cement for mortar;

- wooden beam for the truss system;

- corrugated board or metal roofing;

- chimney;

- door.

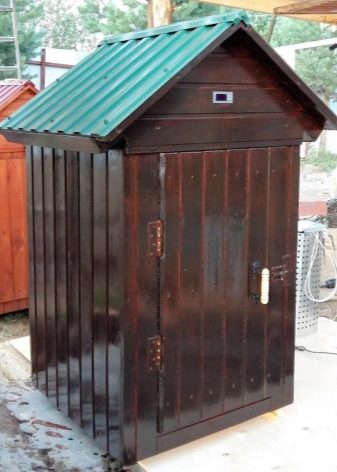

Wooden

There is another material used for the smoking chamber - this is natural wood, which is not only an environmentally friendly product, but also a material that does not emit harmful substances. To create a home smokehouse, wood species such as oak or cherry are suitable. The main thing is that they have a structure that will not be afraid of any negative influences of nature.

To make it, you need to purchase the following materials:

- bars;

- boards up to ten centimeters wide, the thickness of which will be one centimeter;

- boards for roof slopes;

- permeable roofing material;

- brick for the firebox;

- solution;

- waterproofing;

- chimney pipe;

- a sheet of metal to put in front of the firebox.

Components

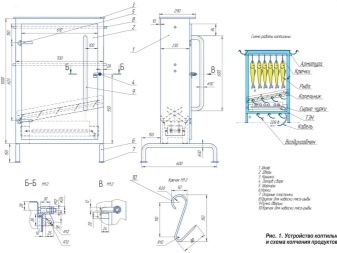

The design of portable smokers is very simple.

It requires the following components:

- smoke generator or oven;

- a compressor used to inject smoke into the chamber;

- smoking chamber;

- an airtight and dense box, on the bottom of which sawdust or small chips are placed;

- a thermostat so that you can adjust the temperature, because it is different for each product;

- fan.

Manufacturing process

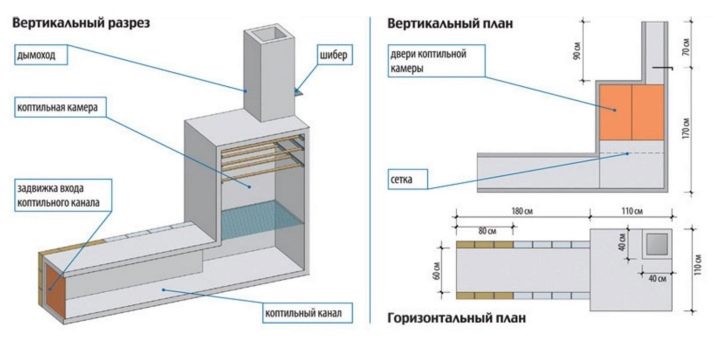

Before you start making a smokehouse at home, you need to make drawings of the future structure. Only after that, using the developed scheme, you can build a smokehouse for cold smoking yourself. First you need to decide on the dimensions of the structure, and then choose a place for it.

Having chosen a brick smokehouse, it is necessary to make a project of this design. This will save time and help you choose the right place to install. The site should have a length of four meters, and it is better if the place is with a slope so that the chimney passes at the right angle. Having made the necessary calculations, you can dig a trench.

First you need to lay the foundation. Then, in the place where the smokehouse will be located, it is necessary to remove the soil. In this case, the pit should be up to 60 centimeters deep. Then a formwork is installed in it, which should be 25 centimeters higher than the edges. Reinforcement is made, and an ordinary bucket is placed in the center of the pit, so that after pouring the concrete, a depression is obtained.

Red brick is used for the walls. The size of the smokehouse depends entirely on the wishes of the owner. In the middle, you can make a small window with an exit to the north side so that direct sunlight does not harm the products.

The roof of a brick smokehouse is lightweight and easy to arrange. To do it, you need to build a rafter system. Either OSB boards or moisture-resistant plywood are laid on them. And only then the tiles are laid on a flat base.

For the construction of the firebox, you can use refractory bricks or a ready-made metal furnace. You will need a fireproof pipe to remove the smoke from the firebox to the smoking chamber. Its diameter should be very large so that the smoke slowly flows and, while cooling, leaves soot particles on its walls. Over the hole where the smoke comes out, grates are placed and foodstuffs to be smoked are hung.

To build a wooden smokehouse, you first need to dig a trench two bayonets deep. It should accommodate the pipe, the combustion chamber and the smokehouse itself. The smoke, getting into the pit, lingers there and is purified, and then rises into the smokehouse.

The door to the firebox must be made of cast iron and securely closing. Its base is made of brick, and the walls are brought out slightly above the ground. Then a wooden structure is placed on it. The trench, where the chimney is located, is covered with earth, and then tamped well. This is necessary to cool the pipe and smoke.

The base for the camera is made from wooden blocks. Then even boards are nailed to it, which should fit very tightly to each other. This is to ensure that smoke does not escape through the cracks. Then a hole is made in the roof into which the pipe is led out.

Any smokehouse, even a hastily made one, should consist of a smoke generator, a smoke duct and a container used for smoked products. If, while on a hike or at a camp site, you want smoked meats, you can make a smokehouse using twigs and plastic wrap.

This design is not at all complicated, but it must be done correctly. The frame is built from poles, a film is thrown on top, and products for smoking can be placed on skewers. Coals from a burnt out fire will serve as an excellent source of heat. For smoke, fresh branches with foliage are suitable. You can build a hearth by digging a hole in the ground or by taking an ordinary bucket for this. The advantage of such a smokehouse is the speed of construction and the absence of purchased material. The disadvantage is that it is necessary to constantly monitor the focus.

This version of the smokehouse is perfect for those who travel to the country for a while and do not want to build a full-fledged smokehouse in their area.

You can also pay attention to such a structure as a smokehouse from a barrel. Wood or other material is perfect for its base. Do not use only plastic. The bottom of the barrel is removed for free passage of smoke. In its lower part, you need to make a compartment where firewood will be stored. Here you need hinges on which the door will be put on. So the compartment can be closed.

Several holes are made in the bottom of such a barrel, which will serve as a blower, as well as a place for removing ash from the furnace.At the height of one third of the barrel, an iron sheet must be welded, which will serve as the bottom for the smoking chamber. For it to last longer, the sheet thickness should be about 4 millimeters.

On the opposite side of the firebox, a hole is made for the chimney. It is folded over and welded to the combustion chamber. Its height should be small, otherwise the thrust will be large enough. Then the temperature will rise, which means that there will be an abundant release of juice and fat. To create an air gap, the legs are welded to the barrel. It will also improve the burning of the wood.

Operating tips

When a smokehouse is available, you can start the cooking process. However, there are some tips to consider. In order for smoked meats to have high taste, you need to make a lot of effort.

It is possible to regulate smoke not only with a damp burlap, but also with fresh branches of trees or bushes. For this, currants or cherries are suitable, which have an incredible aroma. Do not use tree species such as pine or lilac or birch. After all, they contain essential oils, sweet juice and tar, which can saturate foods, thereby making them unusable.

The layer of twigs placed on top of the smokehouse should be approximately 30 centimeters. This is enough for three days. By the state of the top leaves, you can determine the readiness of the product.

When starting to prepare firewood for smoking, you need to know that trees such as pear or cherry are best suited for this. However, they must be barked off before use. If smoking takes place in the forest, then aspen or linden can be used as firewood. To give smoked meats a tart taste, you can take walnut or oak. In order to smoke fish that smells like silt, you must use willow or rakita.

Conifers should not be used, otherwise they can spoil all products. Also, if the trees are infected with any fungi, they should not be taken either.

Also, do not forget about food preparation. Before you start smoking, you need to marinate the meat well. Any method known in cooking is suitable for this. Marinating must be done a day before the smoking process. Also, the meat can be simply rubbed with salt and spices. The finished product will be better stored in the refrigerator.

It takes much less time to cook fish. It just needs to be well gutted and cleaned. Then soak in salted water to eliminate the unpleasant fishy odor. Then soak it in a salty solution and in an hour it will be ready to smoke. Almost any fish is suitable for smoking, both small and large. As a rule, the choice depends on the size of the smokehouse itself and the presence of the necessary functions in it.

Chicken meat is slightly softer than pork, so four hours will be enough to marinate it. Salt and sugar are used for the marinade. Many add wine and spices. This adds flavor to the bird. But you can get by with the classic set of chicken spices.

For pickling lard, a solution of salt, garlic and various spices is used. Marinating lasts two weeks. This is one of the most time consuming processes. However, do not forget to periodically turn the pieces over so that they are equally fragrant and appetizing on all sides. Rinse them well before smoking.

It is also worth knowing at what temperatures and how long this or that product is being prepared. When using hot smoking, products accumulate in different ways. For meat and lard, the temperature ranges from 100 to 150 degrees, and the smoking time is two or three hours of cooking. The fish is cooked for approximately one hour at 70 degrees, which then rises to 100 degrees. The chicken is smoked at 110 degrees for about two hours.

If cold smoking is used, the smoking temperature reaches 30 degrees Celsius. It is because of this that the cooking process takes a lot of time. But the result will delight anyone. After all, such products not only turn out to be very tasty, but also stored for a long time. For example, chicken legs are smoked for up to four days, and then they are kept hanging for another three weeks in a dry room. But they are stored for several months.

For smoking ham, 2-3 days will be enough, but lard is smoked for 7-10 days until it becomes golden brown.

Building a cold smoker will not be difficult and time consuming. One has only to make the correct calculation and choose a place for the smokehouse. And then you can delight yourself and your family with delicious smoked meats, while not being afraid of being poisoned by a low-quality purchased product.

For information on how to build a cold smoking smokehouse on your own, see the next video.

The comment was sent successfully.