Making a goat for cutting firewood with your own hands

What to do if it is not possible to purchase wood sawing goats? Try to make equipment with your own hands. It's quite easy if you follow the instructions and prepare everything you need for assembly in advance.

How to make a wooden structure?

Wood sawing trestles are a simple-to-manufacture design that will simplify the procedure for cutting large blocks into small pieces. In addition, homemade equipment will also help in sawing steel planks and wood planks. You can assemble the goats yourself using a simple drawing. Before starting work, you need to prepare the foundation.

- Wooden block. With its help, it will be possible to quickly assemble the necessary design of the future device. The only negative is low resistance to high humidity. If you plan to store the goats in a damp room, you will need to treat the wood with special compounds.

- Wooden pillars. The advantages include ease of assembly and low cost due to the reduced diameter of the material. Minus - the goats are not particularly reliable.

- Steel profile. An excellent option for assembling a reliable and durable structure that can serve for more than ten years. Cons - the high price, and the need for welding.

And also to assemble the goat yourself, you can use scrap metal. With its help, it will turn out to make a rather simple structure, if you follow the recommendations of the drawings and diagrams.

Before assembling, it is important not only to prepare a drawing, but also to take into account a number of nuances.

- Operator growth. The height of the structure will depend on who will work at the machine. It is important that while cutting the logs, the person does not bend over much and, conversely, does not try to stand on tiptoe.

- Tool dimensions. Sawing logs should be comfortable, so the trestles should fit perfectly under the saw.

- The strength and dimensions of the wood. The trestles must be able to withstand the bars and not deform under their load.

The best solution would be to assemble the machine above one but below 1.1 meters. This is the best option, in which there will not be a strong load on the back and arms. The rest of the dimensions should be selected based on the size of the logs, saws and a number of other nuances that can affect the process of cutting a log.

For working with a two-handed saw

The use of a standard trestle in working with a two-handed saw is impossible, due to the high risk of dangerous situations. One of the most common is equipment overturning, which occurs due to the strong movement of the machine from side to side due to the alternating shear forces occurring during the sawing of logs. Preference should be given to more complex schemes, through which it will be possible to assemble a more stable and durable structure. First of all, you need to take into account a number of nuances.

- The width of the support legs should be increased. This is due to the need to ensure the stability of the structure.

- Additional strapping of the crosspieces of the goat should be provided. This can be done by using a wooden screed. This solution will increase the strength of the structure several times.

- The proportions and dimensions of the machine should be selected in such a way that it is convenient to work on it.The operator should not be exposed to heavy loads and the saw should not be wobbling.

Compliance with the recommendations will allow you to build reliable and sturdy equipment that can cope with the task at hand.

For sawing with a chainsaw

Mostly, ordinary chainsaws are used in homes to cut logs. With their help, it is possible to get small-sized pieces, so small-sized goats are suitable for organizing effective work. The assembly of a simple construction will be an excellent solution for working with a hand-held chainsaw. First of all, you should take care of the materials. Here's what you need.

- A beam with a section of 10x10 cm and a length of up to 1.2 m for the base of the structure. This will be quite enough to organize the sawing of medium-sized firewood.

- Bars with a section of 5x5 cm and up to 1 m long for making legs. Basically, you will need 4 pieces, but it is better to prepare one bar for stock.

- A bar with a section of 5x5 cm and a length of 36 cm for making "horns". You will need 2 pieces.

If you want a more durable structure, you should also prepare a 1-inch block to reinforce the legs of the goat. On average, you will need up to 4 pieces of such supports, but if necessary, 2 will be enough. And you will also need to purchase fasteners to assemble the structure of the machine and ensure its stability and performance. A good solution would be ordinary self-tapping screws for woodworking. The width of the fasteners should not be less than 45 mm and the length should be up to 100 mm. The total number of fasteners is up to 40 pieces. Finally, special impregnations, paints and varnishes will help protect the timber from premature aging and decay.

You don't have to buy everything from scratch. If there are materials from past chores left on the site, they can easily be put into work by assembling an equally reliable firewood sawing machine. So, when all the materials are prepared, you can start looking for the necessary tools. Here's what the operator needs.

- Hacksaw for wood. It will be needed to level the bars in order to increase the stability of the structure.

- Building corner. It will help to make the surface smoother so that the structure does not roll later.

- A simple slate pencil. Needed to make marks for reliable assembly of the machine.

- Screwdriver or Phillips screwdriver. Tools for tightening self-tapping screws.

- Hammer. It will be required to hammer nails into the structure during the installation of the strapping.

- Roulette. Useful for measurements to achieve high assembly accuracy.

- Paint brush. It is necessary to apply a protective coating to the elements of the goat.

And you will also need a chisel.

After the selection of accessories and tools, as well as the selection of the optimal drawing, you can start assembling the goat for sawing firewood.

It is recommended to start work with wood or metal processing, so that in the future there will be no problems in applying protection to hard-to-reach areas. The next stages of the assembly of the structure.

- Marking is performed on wooden blocks, where the saw will subsequently be cut. On average, one goat has up to 12 grooves for fixing the legs and horns. The depth of one groove should be at least 2.5 cm. This will be quite enough to ensure reliable fastening of the elements.

- Next, the structure is assembled, paying attention to the fact that the grooves are 2-3 mm smaller than the legs. This way you can achieve complete fixing of the bars.

- The third stage involves the installation of fasteners. Using self-tapping screws, they install additional structural elements that increase its strength and stability.

- After that, they begin to install amplifiers, through which it will be possible to increase the safety of the workplace, and eliminate the risk of unexpected divergence of the legs during the cutting process. Installation of reinforcements is a simple procedure in which the lower part of the legs of the goat is cut off.The work is carried out so that later additional fasteners can be installed on the legs.

- The last stage is additional processing of wood with special protective compounds. Processing is carried out using a stain, after which the structure is allowed to dry.

When the wood is completely dry, the goats are ready to use.

How to make a metal goat?

If there is no wood at hand, or if you want to make a more durable structure, you can assemble the goats from metal elements. The key advantages of home-made machines for sawing wood from metal are high strength and durability. In addition, metal structures are highly resistant to external influences. To assemble a robust machine, you will need the following parts.

- Profile pipe. Will act as the base of the structure. The cross-sectional dimension of the pipe should be 50 mm in diameter. The total number of pieces is 5.

- Wooden beam with a cross section 50x59 mm and up to 100 mm long, which will act as an amplifier that increases the stability of the structure.

- Electric hacksaw or grinder. Serves as the main tool with which it will be possible to carry out the necessary work.

- A centimeter or ordinary construction tape. They are necessary for preliminary marking of the elements of the future structure in order to determine the places of fixing the parts. And you will also need a standard crayon with which marks will be applied.

- Fasteners. Regular bolts are fine here. And also the connection of the elements can be done by welding, but a welding machine is required.

When everything is ready, you can proceed to the assembly of the gantry structure. Main steps.

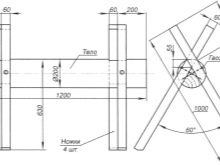

- First of all, you need to draw up an accurate sketch of the future structure. To do this, you should use ready-made drawings and diagrams, or try to design goats with your own hands. The drawing must indicate the dimensions and quantity of each type of element used.

- Next, you need to prepare the beams that will be used as a base. To do this, you will need to use a tape measure and chalk to determine the places where the legs of the future structure will be screwed or welded.

- The third stage involves taking measurements to fix the remaining structural elements. In this case, it is worthwhile to provide for the possibility of bolted or welded fastening, depending on the chosen method of fixation. The first option is suitable for the manufacture of mobile goats, which can be disassembled if necessary.

- When all the marks have been delivered, you can start assembling the structure using fasteners or welding.

- The next stage involves the installation of wooden blocks along the entire length of the machine. This solution will prevent metal from colliding with the saw and will help to avoid deformation or chipping of the latter.

At the end, metal and wood will remain treated with protective compounds to prevent premature aging of the structure.

Recommendations

The process of making goats for sawing firewood is not difficult if you follow the basic recommendations and schemes. Here are some tips to help you make your job easier and give you a chance to get it done right.

- It is better to start the assembly with the preparation of the holes for the fasteners. To do this, you need to put two supports on top of each other, and drill at a distance of 70 cm from the bottom edge of the hole, where the bolts or screws will subsequently fit. Then putting together goats will not be difficult.

- Before starting work, both wooden and metal elements should be carefully processed. To do this, you should use special formulations that are sold in hardware stores. Processing for wood and metal has a different composition, this must also be borne in mind.

- Welding must be carried out in accordance with safety requirements.This means that personal protective equipment must be provided in the form of a special cap, gloves and an apron.

- To make the wooden structure more stable, it is worth aligning the bars in advance with a planer or other tool. It is also recommended to grind the tree so as not to plant splinters during work.

- It is better to make metal machines collapsible. Welded seams reduce the strength of the structure and make it impossible to transport the goat to another location. Therefore, when choosing a connection method, it is better to give preference to bolts.

It is possible to assemble goats for sawing firewood with your own hands. The process includes several simple steps. One has only to find a diagram with dimensions, prepare the necessary tools, and in just a few hours the structure will be ready.

Next, see a master class on making a goat for cutting firewood with your own hands.

The comment was sent successfully.