How to make a concrete pool with your own hands?

In our country, having your own pool is still considered a sign of luxury, and it is not very clear why - if a person can afford a personal plot and built a house on it with all the amenities, then adding another object is not so difficult. Of course, the services of hired workers will cost a lot, but for a person who is used to working with his own hands, the task will be feasible even if there is not much money for construction.

Features of the device of a concrete pool

Regardless of where your pool will be located - on the street, in a bathhouse or in a house, you need to start building it with an adequate project. The drawing must contain a reference to all planned details, including with an indication of the exact dimensions. Only after rechecking several times and making sure that the drawing does not contain errors, you can begin construction.

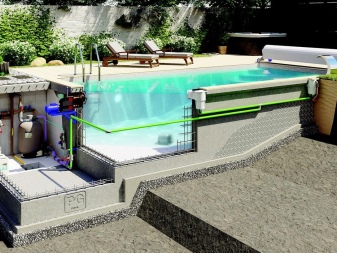

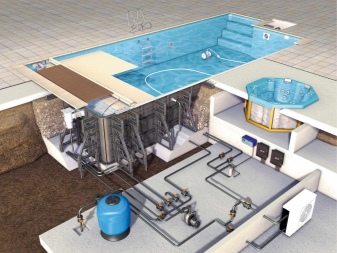

A concrete pool in the country does not differ from buildings made of other materials in anything, except, in fact, the fact that it is made of concrete. The main thing is a bowl that does not allow water to go into the ground without permission. Mandatory pool detail there must be communications designed to pump water into the container and take it out of there after use.

If you want no problems with the supplied water, it is necessary to additionally install pumps (for a stable high pressure), filters (for cleaning from unwanted impurities), thermostatic devices (as a rule, we are talking about a boiler for heating up to comfortable temperature).

This is the minimum set of mandatory details, without which the pool will not be functional. But no one bothers the owner of the territory to expand the project, adding additional amenities there in the form of underwater or surface lighting, foam dispensers, entertainment slides, jumps and waterfalls. Please note that all these parts are installed last in an already operational pool, but their installation must be indicated in the drawing, otherwise you risk not fitting into the dimensions.

Advantages and disadvantages

Concrete is not the only material for making a pool bowl, therefore, all the main advantages and disadvantages of this material should be considered in order to achieve the stated goal.

Let's start with the good:

- cast concrete bowl is different outstanding durability, can withstand significant loads, which means that it has significant service life without replacement or repair;

- concrete can be used both indoors and outdoors - it is a very hardy, versatile material;

- since initially the concrete mixture is poured in liquid form, you can experiment freely with the size and shape of the bowl - your pool can easily turn out to be absolutely unique;

- can be installed on top of concrete aesthetic finishing of almost any kind.

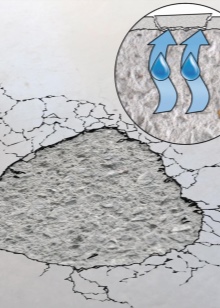

With all the advantages, concrete pools are not devoid of obvious disadvantages. First, be prepared for the fact that the cost of such construction will be significant - the material is very heavy and requires either construction equipment or a lot of laborious manual work. It is necessary to work with it carefully and strictly according to technology, otherwise the notorious strength and durability may turn out to be fiction.For concrete pool reinforced waterproofing required, but even this does not save 100% from the fact that the fungus spreads well on the concrete surface - which means that the container will have to be regularly cleaned and disinfected.

If the structure is being erected in the open air, for beauty and greater security, it is often trimmed with mosaics or tiles, but in this case you should definitely not save on high-quality glue, otherwise you will very quickly face the fact that the cladding falls off and the bowl no longer looks aesthetically pleasing.

Views

Although the concept of a concrete pool in itself seems to be quite capacious and describes the structure in detail, in fact, such plumbing structures are classified according to other criteria. Least concrete bowls can vary in size and shape, design, installation location - for each of these criteria, you can come up with a lot of options. They are often divided into public, which is hardly relevant in the country, and household.

There are also swimming pools (the exact distance of the path is important, a significant depth is characteristic), teenage and children's (have reduced size and depth), as well as those pools that are not intended for one age category - their bottom can even be multi-level.

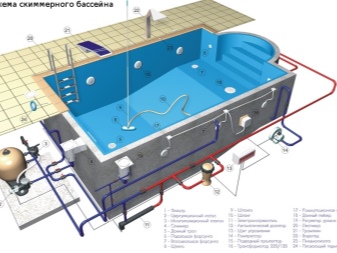

The key criterion for classification is often called way to drain excess water. The so-called skimmer system assumes that at least one of the walls has a hole that can be compared to a bath overflow. Such a hole is located in the upper part of the bowl, it provides that it is simply impossible to fill the pool with water above this level. From skimmer (this is the correct name for such an overflow) moisture almost immediately gets to cleaning.

Pools with overflow system arranged a little more complicated, and it is quite rare to see a concrete structure of this type. Such fonts are filled with water to the very edge, but along it, in the immediate vicinity of the edge of the pool, there are drainage trays closed by gratings - according to the principle of a street system for draining rainwater.

Since overflow can occur from different sides of the pool at the same time, such an overfill protection device turns out to be more complex, and the water on its way to the treatment plant overcomes a more difficult path.

Material selection

Concrete pools are often described as the most reliable and durable, after all, such a design is capable of serving a good hundred years, while a cheaper and simpler polypropylene one - a maximum of thirty. Nevertheless, it will be possible to achieve such impressive indicators only if you do not save on concrete and choose the right composition.

First of all, the highest concrete density is required - the brand should be at least M350, and even better it will be guided by M400 Portland cement. The water resistance of the latter material must be at least W6, also make sure that the material has good indicators of frost resistance - not lower than F100. If the structure is being erected inside a heated room, the last requirement can be slightly reduced, but it is still not worthwhile to get carried away with the savings.

Even good, heavy concrete will not be hindered by additional additives - plasticizers and hydrophobes.

The proportions may fluctuate somewhat depending on the conditions in which the font will be used, what dimensions it will have, but experts advise to spend the following ingredients as a good "recipe" for a cube of concrete:

- Portland cement - 6 centners;

- medium-grained sand - 16 centners;

- fiberglass - 8 centners;

- microsilica - 60 kg;

- plasticizers - 1 kg.

If you decide to fill a concrete pool, do not experiment with the use of any other materials used in construction - for example, with aerated concrete, composite, expanded clay and other blocks, as well as well rings. Despite their undoubted value in the process of erecting buildings, they are still not adapted for the construction of artificial reservoirs, they can absorb and pass moisture.

The permissible maximum of their use is as permanent formwork, which is hidden inside the structure, but even in this case, you must choose the most dense and durable version of the product. Faced with the need to spend a lot on such a formwork, you will most likely simply give up such an undertaking.

Construction technology

To achieve the most positive result, you must follow a few simple rules, neglect of which will surely result in subsequent problems during operation. First of all, as already mentioned, you need to draw up a competent and detailed drawing with dimensions. It is necessary to make all the calculations and recheck them on the diagram, and not after the work has been completed. You must take into account absolutely everything, including the thickness of the embedded walls and the bottom, and choose a site so that, taking into account the margin of thickness, it is located quite far from large trees - their roots can greatly worsen the longevity situation.

No matter how high-quality the concrete solution may seem to you, when building a pool on the street you must use additives... With their help, you will achieve the minimum porosity and increase the plasticity of the mass.

Concrete will become more reliable to adhere to the reinforcement cage and acquire hydrophobic properties, as well as learn to withstand temperature changes.

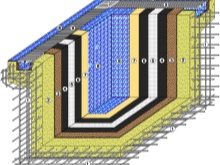

A concrete pool is considered to be monolithic, but in fact there is one seam - between the bottom and the walls. It must be carefully sealed - for this, the joint is treated with substances that increase adhesion, and then filled with a special cord that has the ability to expand at high humidity. A sufficient coat of waterproof sealant must be applied over the cord.

Facing the bowl on your own, you must use only durable, waterproof adhesive. For all the strength of the concrete bowl, it is the tiled lining that performs the main protective function against water destruction, therefore, not only glue, but all these grouting and plasters must also be strictly waterproof.

Step-by-step manufacturing instructions

Swimming pool construction starts with design - if the font is located in the house, then it is better to build it at the same time as the building. With such Napoleonic plans, it is better to entrust the design to specialists, but the project of an outdoor pool can be done by yourself. Think about whether the sides should be above ground level or level with it, calculate the area of the mirror, taking into account the standard of 5 by 2 meters for each person. In a pool without a springboard, the depth usually does not exceed one and a half meters, if there is a springboard, at least 2.5 meters is necessary, while at the point of discharge, the depth can be about 20% greater. The thickness of the walls and the bottom depends on the soil - if it is heaving, it should be made thicker. Decide how to enter the pool - stairs or steps. Standard parameters are wall thickness 20 cm and bottom 25 cm.

Dig a pit with a decent margin - waterproofing should also fit in there, at the surface the diameter should be much wider so that the soil does not fall off the walls. Level the bottom and tamp, then fill in a pillow of a 35 cm layer of gravel or crushed stone and cover with sheets of film or roofing material with an overlap of up to 20 cm and a vertical bend around the edges, you can glue geotextiles.

Then perform reinforcement of the bowl using a durable metal mesh with cells of 20 x 20 or 25 cm. The reinforcement needs to be ribbed, with a diameter of at least 12 mm, it will have to be cut, since it is sold in coils.It is correct to start the reinforcement from the bottom, laying the grating on the placed bricks, after completion, the bottom should be immediately concreted and leveled. While the bottom dries, proceed to the assembly of wall reinforcement.

The walls cannot be poured until the bottom is completely dry. - it can take a whole month, and even special additives will not solve the problem in less than a week or two. On top of the reinforcement from boards, plywood and other similar materials, formwork is assembled according to the future shape of the walls, reinforcing it every 50 cm with stiffeners. Pouring is carried out within one day, the concrete is pierced with a stick for better compaction and covered with foil. You can sometimes wet the concrete to make it stronger. The formwork is removed after a week or one and a half, but the walls should take longer to dry. The steps, if any, are poured only after the entire bowl has dried, they are made according to the same scheme: frame - formwork - pouring, concrete is needed of the same brand.

Outside, the bowl is waterproofed with cement with polymers and reinforcement mesh. Liquid rubber is also suitable, which does not crack even when the bowl shrinks. From the inside, you can cover the bowl with film roll waterproofing, but a different finish will be needed on top of it - you will have to paint or plaster the bowl inside. Let all formulations dry, then check the bowl by pouring water into it.

Only if no leak is found, the water is drained and proceeded to the next stages. These include insulation against heat loss, steam and leakage. After that, the pool is finished and any additional accessories installed.

Arrangement of drain

In the design process, it is most reasonable to think immediately 2 ways to drain water - if one breaks, then the second will back it up. The simplest drainage option is to install a bottom connection with the sewer, then the water can come out even under its own pressure, especially if the bottom drops from all sides to the area with a drain. The sewer pipe must go down at an angle, otherwise you will not drain the water without installing the pumps. For pools of a small size, it may be appropriate to drain into a cesspool or septic tank.

note that using pool water to irrigate the garden beds, or draining it into natural bodies of water, are not good ideas - there is a lot of disinfectant chemistry. The installation of filtering equipment and the creation of a sump can partially solve the problem.

Operating tips

For a comfortable use of the pool, the bowl must be kept clean. Large debris can be caught with a net, the walls can be cleaned with a special scraper, the bottom is cleaned with a special bottom vacuum cleaner. Filters need to be rinsed regularly, otherwise they will clog and stop functioning. Do not forget to check the composition of the water with special indicator strips, in case of detection of impurities, disinfect the liquid with hydrogen peroxide or chlorine.

To close the crack, if it appears, you need to immediately - resin solution is introduced there. If the size of the damage is small, it is better to immediately knock on the surroundings to crush the cracked concrete, clean it 30 cm in each direction, coat it with epoxy three times. The cladding, if present, should be glued back in the same way as it was originally glued - certainly in a completely dry bowl. If you see the pool is leaking drain the water and carefully examine the walls for cracking, upon detection, proceed as described above.

If the pool was designed without taking into account the bathing of small children, now you need to create safe conditions for babies, reduce the depth most reasonably with the help of a special prefabricated bottom. This design is very similar to store pallets and is made from different materials.Its advantage is that the false bottom can be quickly removed at any time and assembled again, assembled from parts that make it possible to roughly fit the new bottom to the shape of an artificial reservoir. If necessary you can contact the manufacturer to order a false bottom, ideally suited to the size and dimensions of your particular pool.

How to make a concrete pool in the country, see below.

The comment was sent successfully.