PVC pipes for pools: features and choices

Today, in order to swim in a reservoir, it is not necessary to go to a river, lake or sea - you just need to install a pool at home. This reservoir (artificial reservoir) is an excellent solution that will help diversify everyday life and make it more fun, especially for children.

But just buying a pool is not enough - it needs to be properly assembled and installed. In the process of installing the structure, pipes are an indispensable element. They are connected to a pump, a filtration system, that is, they connect all the equipment that takes part in the functioning of the tank, and provide continuous circulation of water. Today everyone uses exclusively PVC pipes, it is about them that will be discussed in the article.

Features, pros and cons

Pipes that are used for the construction of the engineering part of such a hydraulic structure as a swimming pool are made of adhesive pressure PVC. They are characterized by:

- high mechanical strength and resistance to deformation;

- the possibility of using them in the process of installing a pressure pipeline;

- minimum linear expansion when heated;

- perfectly smooth inner wall, which excludes the possibility of the formation of algae, mold and other microorganisms;

- full resistance to corrosion and aggressive effects.

In addition to excellent technical parameters, PVC pipes have other advantages that made the product a leader in this area, namely:

- ease (thanks to this criterion, installation work can be performed alone);

- high strength factor;

- long service life;

- frost resistance;

- cost (this type of plastic is one of the cheapest and most affordable).

Of course, disadvantages should be noted, which include:

- contact with water, the temperature of which exceeds 45 ºС, is not allowed;

- PVC pipes are destroyed by prolonged exposure to direct sunlight, the ideal option is to put them underground.

As you can see, there are much more advantages, and the disadvantages that are inherent in this product are quite easy to get around.

Types and sizes

The assortment of PVC pipes, which is presented today on the sanitary ware market, is very diverse. They are of two types.

- Tough Is a straight line with a maximum length of 3 meters. Ideal if you need to lay a straight section. These pipes are adhesive, they are connected using a special compound.

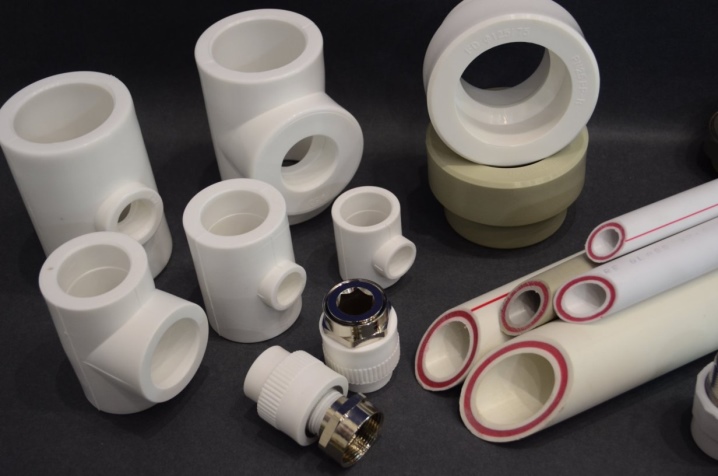

- Soft - sold in the form of a bay, the length of which can be 25, 30 or 50 meters. The connection involves the use of special fittings, also made of plastic.

You can choose absolutely any of these two options, each of them is suitable for installing the pool piping.

Also, PVC pipes may differ in other parameters.

- The type of fixation of the elements. The cold welding method (using a special adhesive) or the brazing method, when the pipes are connected with fittings, can be used.

- Strength factor. The ultimate strength for the pool is 4–7 MPa. The maximum pressure limit that the pipe can withstand depends on this parameter.

- Inner diameter size. This parameter can be very different: from 16 mm to 315 mm. In most cases, preference is given to PVC pipes with a diameter of Ф315 mm. The thing is that this one is great for the pool.

Selection Tips

You need to carefully choose PVC pipes for the pool, because not only the functioning of the structure depends on their quality and compliance with all technical characteristics, but also the effective operation of the equipment that is connected to the pool. The latter, in turn, regulates water quality, which can affect human health.

It follows from this that when buying PVC pipes, you need to consider:

- pipeline diameter;

- technical specifications;

- the quality of the raw materials used in the production process;

- type of PVC;

- manufacturer;

- price.

Each of the above criteria is important. Experts recommend paying special attention to the manufacturer. It is best to choose products of a well-known brand, even if it is more expensive. It is also advised to buy everything you need in one store (pipes, fittings and glue) and from one batch of goods.

Installation nuances

Despite the fact that the installation of the PVC pipeline and its connection to the pool is quite easy and can be done independently, there are still a number of features and certain nuances that you need to know about.

In the process of laying, the application of the cold welding method is relevant, when all the elements of the pipeline are connected to each other with a special glue.

Adhesive joints are more tight, durable and reliable, and given that the pipeline is laid for a long period and it is not intended to be dismantled, this is a very useful property.

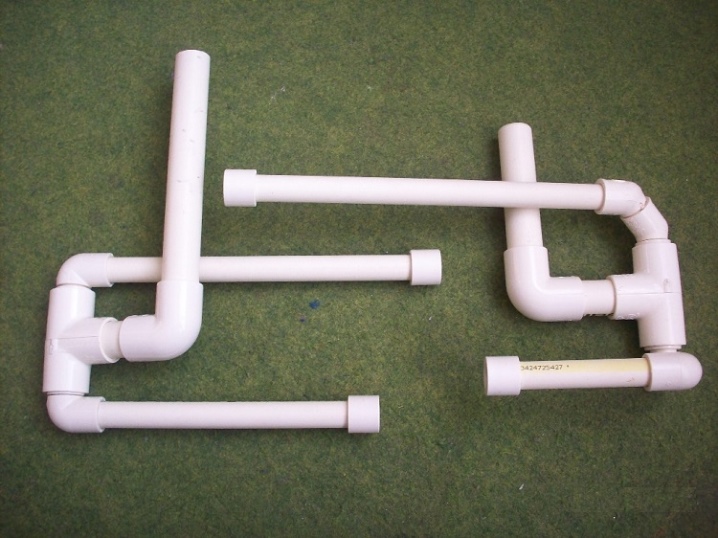

So, the process of laying PVC pipes consists of the following stages:

- choice of pipes - you need to buy and use them only for their intended purpose, like sewer pipes, for this, if necessary, contact a consultant for help;

- selection of glue - you need to choose a quality product with a certain density and viscosity coefficient;

- purchase of fittings (couplings and tees, bypasses and taps, plugs, clamps and fasteners), it is desirable that these connecting elements are of the same brand as the pipes;

- digging a trench, the depth of which should be below the level of soil freezing;

- preparation of pipes - cut them to the required length, process all joints with sandpaper, degrease;

- processing of joints with adhesive sealant;

- pipeline connection - each joint is connected for about 3 minutes, this time is enough for the glue to start hardening, of course, if it was chosen correctly;

- removal of glue residues on the pipe.

The work must be done carefully and slowly.

After the pipeline is assembled into a single structure, it is connected to the pump and filtration unit.

There is another method that can be applied during the installation process - hot. The first three points of the pipeline laying process are similar to the previous method, only instead of glue you will need a special tool - a soldering iron. With its help, all structural elements of the pipeline system are connected. To use this method, you need to own a tool and know the technology for performing soldering work.

The solder connection method is not used very often. The fact is that it is more expensive (in terms of time) and is not particularly reliable.

In the next video, you will learn how to glue PVC pipes and fittings for swimming pools.

The comment was sent successfully.