Bowls for the pool: types, manufacturing technology and installation

Currently, private pools in the country or in a country house are considered commonplace, and they can be built in a short period of time. However, in order for the reservoir to please all family members, it is necessary to choose the right bowl, which is the basis.

Views

First of all, you should consider the types of water exchange systems. They may be both overflow and skimmer.

In the overflow basin, the water level reaches the very edge. There are overflow troughs through which excess liquid is removed. The tank is equipped with an automatic topping-up system, water is collected in the storage tank, from where it is sent for cleaning and heating, then it moves back into the bowl. This system is more expensive, but the cleaning is at a very high level.

The skimmer system is used for reservoirs with right angles. With the help of a circulation pump, the liquid enters the skimmer and the bottom drain, from where it goes for filtration. The cleaning is pretty crude. Then the water is heated and disinfected, after which it enters the bowl again. In this situation, it is advisable to use special vacuum cleaners to clean the bottom.

In addition, the pool bowls can be divided into monolithic and prefabricated. In the first case, we are talking about a one-piece tank. It is considered more reliable, and its installation does not cause any particular difficulties.

The prefabricated version, as the name implies, consists of several separate parts, which are connected using special equipment, which requires additional time and effort during the installation stage.

Materials (edit)

The materials used to build an outdoor pool are neither good nor bad. Each has its own advantages and disadvantages, and is also intended for different conditions of use. Let's consider the most popular options.

PVC

PVC bowls can be called an alternative to a fully built pool. This option is quite often used in water parks, it is also used in the adjoining territories. The design is not very durable, but at the same time it is simple and does not require serious financial costs.

The material is film resistant to ultraviolet rays. It is often coated with a layer of acrylic to provide a matte sheen. It is considered a huge advantage that there is no need for additional waterproofing.

However, PVC does not tolerate sharp critical changes in temperature, so such tanks can only be used in the warm season.

Composite

These materials represent high strength fiberglass... They are lightweight and completely sealed. However, at the same time, composite bowls are expensive, since their production is rather difficult.

Among the advantages, it can also be noted that in most cases, composite bowls have additional elements in the kit. These can be steps, platforms and other products. And also the material can be called very durable, because several layers of plastic are used in the production. This directly affects the duration of operation.

It should be noted that such bowls cannot boast of a wide range of colors. They are predominantly blue or white.However, if you wish, you can order a certain color.

Composite bowls do not cause any difficulties during the installation process. They can be installed both outdoors and indoors.

Acrylic

Acrylic pool bowls are considered a new variety. During the production process, the polyester fiber is reinforced with fiberglass, which is the basis of the composition. The material turns out to be perfectly smooth and durable, in addition, it is flexible.

Such materials do not weigh too much, which makes them easy to install and transport. They are not afraid of corrosion and other unpleasant phenomena typical for a humid environment. And also the tank is able to withstand temperature changes well, therefore it can be used both in heat and in frost in the form of a skating rink. Acrylic bowls are not afraid of exposure to sunlight and do not fade. All of the above properties allow them to be used for a long time.

Concrete

It is not so easy to build a concrete structure on the site. For this certain construction skills or the help of professionals are required. In addition, the process turns out to be quite lengthy and requires serious financial costs. It includes several main stages.

First of all, you should attend to the design. It depends on him how successful the planned building will be. Erection mistakes can be too expensive, as the strength of the structure depends on various factors, therefore all calculations should be verified as much as possible.

Concrete pool bowls, according to user reviews, are the most durable and can also be used for a long time. An important role in this is played by how high-quality materials were used, and how professionally the work was carried out. The shape and size of the tanks can be anything, it all depends on the preferences of the owner. There are no restrictions in decoration, therefore the design will look organic in any environment.

Such pools can be equipped with any additional products and accessories. They are often used for medicinal purposes. Therefore, this option is considered the most convenient and successful.

Metal

In the design and construction of swimming pools, a material such as stainless steel cannot be ignored. Metal bowls can be used for a long time. The surface looks very original, and it is also pleasant to the touch.

If we compare metal bowls with concrete ones, one cannot fail to note their lighter weight. Such tanks can be placed not only in the basement or on the street, but also on any of the floors of the house. However, it should be borne in mind that in this case, the base will be made of concrete, which should be as even as possible.

The walls of the bowl are made of welded metal sheets. Their standard thickness is 2.5 mm, but this is not required. Indicators may change depending on the situation.

The thickness of the steel used for the bottom must be 1.5 mm. Most often it is grooved to have an anti-slip effect.

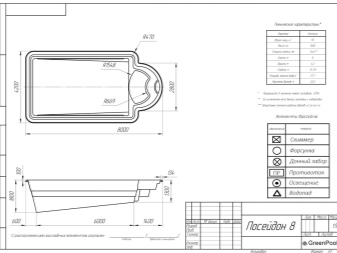

Depth and shape

The indicators of both the depth and the shape of the pool are purely individual. In the first case, you should focus on the growth of bathers and their average age. TO for example, for kids under 5 years old, a bowl up to 50 cm deep will be enough.Older children, up to 12-13 years old, should install a pool up to 80 cm deep. an ordinary pool, and not a jumping one, the initial depth of which should be from 2.3 m, depending on the height of the tower.

Do not think that the deeper the bowl, the more comfortable the pool will be. The fact is that an increase in depth entails an increase in costs, in some cases completely unreasonable. Both construction and maintenance require financial costs. Experts recommend dividing the pool into zones with different depths, some of which can be used for swimming, and others for jumping from a tower.

As for the shape, the most common are round, rectangular and oval pools. The last option is considered the most convenient. Users note that it is comfortable to swim in it, and the absence of right angles affects safety. In such bowls, water circulates better and does not stagnate in the corners, and there is also a more uniform pressure on the walls.

However, the choice of form is also at the discretion of the owner. It is influenced by the location of the pool and a number of other nuances.

Finishing options

After installing the pool, the finishing option becomes an important issue. Most often, in this direction, ceramic tiles, a special polyvinyl chloride film or mosaic are used. In some cases, the owners prefer natural stone, liquid rubber or paints and varnishes.

The PVC film has 4 layers and a thickness of 1.5 mm. It is reinforced with polyester fiber. Special stabilizers help protect it from fading and cracking when exposed to sunlight. The acrylic layer gives an effective glossy shine.

The most popular finishing material for the capital construction of the pool is ceramic tile... The bowl most often has a glazed coating that gives shine, but anti-slip elements are used for the steps. Experts note that large tiles are less preferable. The fact is that it is more susceptible to deformation under the influence of water.

Often used and treatment of the bowl with special paint. However, this process is labor-intensive and time-consuming. Violation of the work technology can lead to sad consequences.

The paint and varnish wet coating does not slip, it tolerates temperature fluctuations and physical activity well. However, it is not recommended to use it in outdoor pools, as it will need to be renewed annually after winter. As for covered tanks, the service life is increased to 3-5 years.

How to choose?

When choosing, you must first evaluate the appearance of the product. It should not have scuffs, chips or other defects. The surface should look smooth. And you should also decide on the material, size and shape. These indicators are directly influenced by the purpose.

When buying a bowl an important point is the optimum temperature for its operation. If we are talking about an outdoor pool, and winters in the region of operation are rather harsh, a product with permissible use up to -25 degrees will not work. Therefore, the climate of the area should also be taken into account.

Next, you should inquire about the guarantee... Some manufacturers indicate rather long periods, up to 30-100 years. Only large and well-established companies can be trusted in this.

How to install a finished bowl?

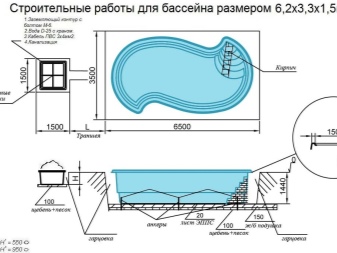

To install the finished bowl, you will need to mark the site. After that, a pit of the required size is pulled out. Its depth should be 50 cm higher than the depth of the tank. At the bottom, sand is poured and compacted to a depth of 20 cm, on top of which a metal mesh is laid and poured with a layer of concrete. These works will just remove the extra depth.

After the solution has solidified, the reservoir should be insulated. Geotextiles and expanded polystyrene are laid on concrete. The same materials are applied to the walls of the bowl and packed with polyethylene for insulation.

After placing the bowl in the pit, it is necessary to carry out communications. A special protective sleeve is usually used. Empty cavities are filled with concrete.

Spacers should be placed inside the tank, formwork should be made and reinforcement should be laid around the perimeter. The concrete is poured in layers.For this, the bowl is 30 centimeters filled with water, and concrete is poured to the same level. After solidification, the procedure is repeated. Dismantling of the formwork is done not earlier than in a day.

How to clean?

Manual and semi-automatic methods can be used to clean the pool. In the first case, water is drained from the reservoir, in the second, this is optional.

For manual cleaning, special compounds are used that should not get into the water. It is relevant for small bowls. Mechanized cleaning is carried out using underwater vacuum cleaners and requires additional water filtration afterwards. You can do the procedure yourself if you have concentrates and equipment, or you can contact a specialist.

The installation of the pool bowl is shown in the following video.

The comment was sent successfully.