Do-it-yourself grain crusher

Industrial grain crushers sometimes cost tens of thousands of rubles. The independent production of grain crushers from household appliances, in which, for example, gearboxes are worn out and cannot be replaced, allows reducing costs up to several times.

Design features

A grain grinder is like a coffee grinder enlarged 10-20 times.

But the difference between the one and the other machine lies in some parameters.

-

Unlike a coffee grinder, a grain crusher grinds the grain not into a fine powder, like a powder, but into a coarsely coarsely ground substance.

-

The grain crusher is capable of grinding from tens of kilograms of grain in one grinding session.

-

The more grain you need to grind, the longer the device will last. For example, to satisfy the monthly requests of a chicken coop, in which, say, 20 chickens lay eggs every day, it will take more than one hundred kilograms of grain. To grind 10 buckets of the same wheat or oats, it will take at least one and a half hours of operation of the unit.

The design of the grain crusher includes a number of components.

-

Protective housing - made of metals, plastic and / or composite.

-

A support that is permanently installed in a specific place, or removable (portable).

-

Bracket adjustable with nut and bolt.

-

The second base has a softener in the form of a rubber "shoe".

-

A pair of motors and as many sets of 6 cm diameter pulleys. They rely on mortise bolts and keys.

-

Seals that cushion vibration from motor shafts.

-

Knives that grind grain and grass. Both of the cut ingredients are the basis of the compound feed.

-

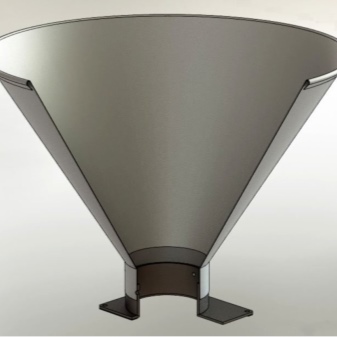

A lidded funnel into which unmilled grain is poured. The second funnel allows the crushed raw material to pour out into a previously prepared container.

-

Frog lock.

-

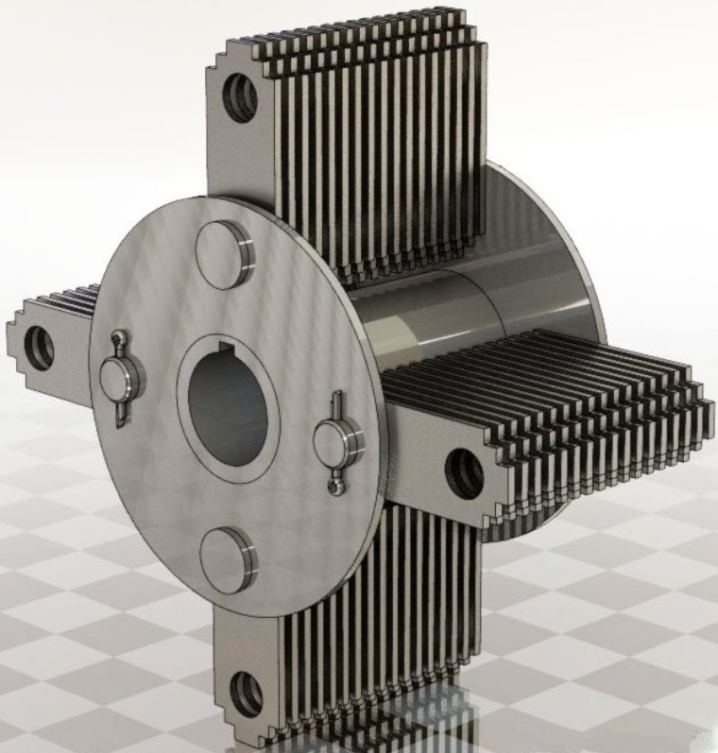

Removable grids that allow fractions of different sizes to pass through.

-

Rubberized wheel.

Each of the above components can be easily and easily mounted on an old washing machine.

A grain crusher made of an activator washing machine (or automatic machine) is a device that has the highest performance and capacity compared to similar fabricated from other electrical appliances.

Components selected and / or made by hand must be compatible with the overall dimensions of the final device. No one will install knives several times smaller in diameter in the tank for an activator washing machine - the operation of such a device would become extremely ineffective. The volume of grain, normally milled in 20 minutes, with reduced knives, would take an hour or an hour and a half. In other words, a homemade device is physically balanced.

Similar to the coffee grinder device, the knives in the grinder, combined with the shafts of the electric motors, are immediately started when the device is connected to the household lighting network. They finely chop small branches, seeds and grass. The crushed raw material goes to a sieve that removes husks and small debris. What has passed the filtration passes into the container through the funnel, collecting in it.

What can be made of?

Let's consider how to make different components for a grain crusher at home.

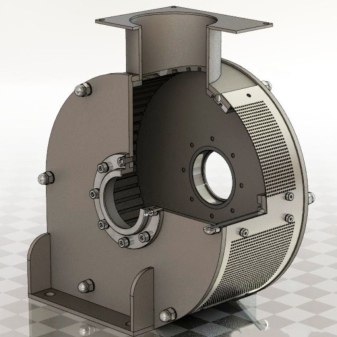

- The grinding tank is made of thin (0.5-0.8 mm) stainless steel. A metal frame with a valve is fixed next to the base. The outer part of the body is made of a seamless metal tube with a diameter of 27 cm. The wall thickness of this tube can be up to 6 mm. Inside the same pipe, a stator is installed, for the manufacture of which a pipe of slightly smaller diameter was used - for example, 258 mm. Holes were drilled in both pipe sections for securing the loaded hopper, removing the crushed grain, mounting a grate with the required mesh size, hangers for securing the unloading hopper. Both pipes are mounted in such a way that they are held in the slots of the auxiliary flanges located on the side. The latter are connected to each other using several pins. One of the flanges has an internal thread for studs. The second one is drilled in several places. Both flanges also have holes drilled through to secure the bearing housings and are secured to the metal frame with bolts and nuts.

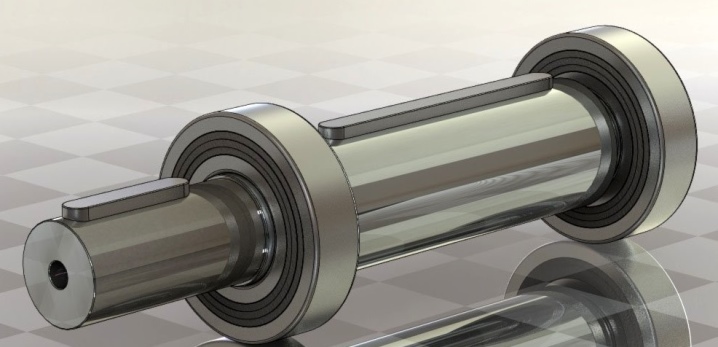

- The rotor is assembled on the basis of prefabricated metal pushers and is equipped with washers. These pushers can be turned over if necessary. After assembly, the rotor is checked for imbalance. If beating is still detected, the rotor is balanced immediately - parasitic vibration can shorten the life of the entire device.

- The drive shaft contains keys and ball bearing kits. Protective washers for ball bearings are based on the requirements of GOST 4657-82 (size 30x62x16).

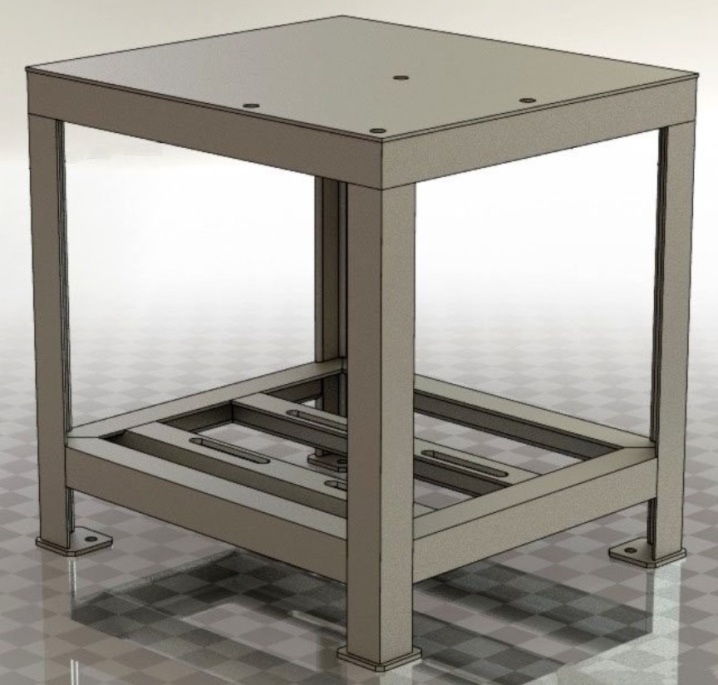

- The supporting frame with the table is manufactured in a welded version. The starting material is a steel corner 35 * 35 * 5 mm. The valves are manufactured from thin sheet steel.

Having prepared the necessary materials and blanks, they proceed to the assembly of the grain crushing device.

Schemes and drawings

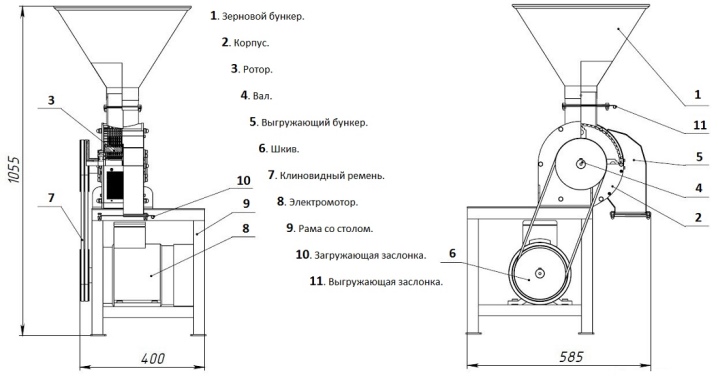

A grain crusher from a washing machine contains the following components:

-

grain bin;

-

frame;

-

rotor;

-

shaft;

-

unloading hopper;

-

pulley (the requirements of paragraph 40 of GOST 20889-88 are observed);

-

V-belt;

-

electric motor;

-

frame with a table;

-

loading and unloading gates (valves).

Drawings of analogs made on the basis of a vacuum cleaner motor, an electric drive of a grinder, a drive and a meat grinder mechanism, differ little from a device worked on the basis of a (semi) automatic washing machine. The principle of operation of the device is no different - which cannot be said about the type of chopping mechanics used.

Step-by-step manufacturing instructions

For a do-it-yourself grinder, the following household appliances that cannot be repaired are suitable: a semiautomatic washing machine (may contain a brake drum), a grinder, a vacuum cleaner and other similar devices based on a commutator or asynchronous motor.

From the washing machine

To make a grain crusher based on mechanics from a washing machine, several steps must be taken.

-

First, make your cutting knives. They are ground on a grinder and additionally sharpened with sandpaper.

-

Set the knives so that they intersect with each other. The indents in each direction should be the same, symmetrical. They form a four-pointed star.

-

Having fixed the knives, for example, with a clamp or a vice, they are aligned, at the point of intersection, a common hole is drilled through. The diameter of the hole is selected optimal - for rigid fixation on the shaft, which transfers the kinetic energy of the operating motor through the pulley. The shaft itself is located in the area of the built-in activator.

-

The shaft is secured with a wrench (an adjustable wrench can be used). Press washers are required to secure the shaft.

-

Mount the knives that were sharpened and drilled earlier on the structure shaft. Both torches are fixed one after the other on the shaft (axle) and clamped by means of clamping nuts. As a result, each of the knives will be located on a separate horizontal.

-

Using the drain hole of the washing machine, through which waste water was previously removed, equip the funnel. To allow the crushed material to spill out quickly, lengthen the funnel up to 15 cm using a round file and a hammer. Place a piece of pipe in the widened hole and give the resulting descent a direction that is convenient for the user.

-

Mount the metal mesh by tilting it 15 degrees. The edges of the net should not form a gap through which untreated grain would pour out. A correctly installed mesh will allow the user to quickly and efficiently clean the crushed grain from the chaff. It will be easier for the crushed raw materials to penetrate into the container previously set for its collection.

The installation of the largest mesh is much easier than the smallest one (which we could find). Follow a series of steps to properly install the filter sieve.

-

Measure the level of lift of the cutters beyond which they will not rise. Run the engine test - at low rpm. Mark this height on the sides of the hopper. Move another centimeter away from the marked marks by drawing a line in this place.

-

Mark and cut the grate (mesh) so that the dimensions of the intake funnel coincide with the cut out fragment.

-

Place this piece so that its edges go along the previously marked line.

-

To seal the attached mesh - or rather to prevent intrusion of unmilled grain - apply a layer of adhesive sealant around the delineated perimeter.

The device is ready for testing. Put the grain to be milled into the pick-up hopper and start the engine.

It will be useful to use an electromechanical timer that previously turned off the engine at the end of the wash cycle.

Make sure that the grain has been crushed to the correct size and has passed the shelling stage. The resulting fraction must all overcome the filter sieve. Check the operation of the knives - they should handle the first batch of processed grain to the fullest. The motor and the crushing mechanism itself must not get stuck, slow down to a complete stop. Extraneous sounds unusual for a crusher in operation should not appear. With successful testing, the grain crusher will serve the user for many years.

From the grinder

A characteristic feature of the manual electric grinder is the axis located perpendicular to the cutting disc. To make a grain crusher from a grinder (grinder), do the following.

-

Mark and saw out a rectangular piece of thick (1 cm or more) plywood.

-

Saw out a round hole in the cut piece of plywood - in the shape of the main structure in which the cut-off wheel rotated.

-

Secure the plywood with the bolts and the supplied metal bracket. The axis of rotation must point downward.

-

Make a cutter from a suitable length, width and thickness steel strip. As in the previous case, the knives must be carefully sharpened and centered. Insufficient centering can break the angle grinder gearbox over time.

-

Not far from the angle grinder mounted in the tank for crushing grain, make a hole and provide it with a funnel. Through it, unmilled raw materials are poured into the grain crusher. The funnel with a hole is not placed under the Bulgarian drive, but above it.

-

Install a sieve made from a used pot below the drive. It is drilled with a fine drill (about 0.7-1 mm).

Collect the grain grinder. Place it on a pallet or box. Place, for example, a bucket under the lower funnel where the crushed raw material is poured. The funnel can be made from the cut off top of a food grade plastic bottle - the diameter of the neck is enough for the poured grain to easily and quickly pass into the grinder.

From a meat grinder

You can make sure that the meat grinder will grind the grain, you can use resins, for example, hazelnuts or walnuts in a shelled form.There is no need to make a knife that acts as a cutter "from scratch" - it is already included in the kit. For the finest grain fraction, it is necessary to use the finest standard sieve, which is also included in the delivery set.

In order for the grain to be rinsed continuously, it is necessary to install a large funnel above the grinding mechanism, for example, from a 19-liter bottle, from which the bottom is cut off.

A hole of diameter is made in the lid, at which the poured grain will not pass through the neck faster than it is passed in crushed form through the grinder of the meat grinder. In principle, there is no need to modify the meat grinder in any way. The grain should not be too hard - not all meat grinders will cope equally effectively, for example, with durum wheat. If you cannot use the grinder as a grinder, use a coffee grinder.

Other options

The most popular version of the grain crusher is a homemade device based on a vacuum cleaner that has come to the end of its useful life. The easiest to modify are Soviet vacuum cleaners based on a collector motor with simple mechanics - "Raketa", "Saturn", "Uralets" and the like. Follow a series of steps to make a grain crusher from a vacuum cleaner.

-

Remove the motor from the housing.

-

Dismantle the suction line (it contains a specially designed propeller) by disconnecting it from the motor shaft.

-

Cut the rounded base out of a sheet of steel. Steel thickness - at least 2 mm.

-

Using the center, cut a hole in the cut out steel section for the motor shaft.

-

Cut a second hole at some distance from it. It serves as the entrance to the grain bin.

-

Secure the motor to the steel base using bolts and clamps.

-

Install a trapezoidal knife, previously turned from the same steel, on the motor shaft.

-

Place a sieve made from an old saucepan under the cutter. The diameter of the holes in it should not exceed the size of half a centimeter.

-

Fix the assembled grain crusher on the receiving container with staples and screws.

The opening for the grain tank, into which the unprocessed grain is fed, is located in the range of the cutter. An unrepaired technological gap, into which the cutter does not fall, will lead to a significant spillage of uncrushed raw materials under the sieve. As a result, the latter will be clogged, and work will stop.

Instead of a vacuum cleaner, you can use a drill, a hammer drill in a non-shock mode, a high-speed screwdriver as a drive. The power of the latter is not suitable for hard grain varieties.

Recommendations

To keep the shredder's performance high, follow the advice of a specialist.

- Insulate the motor with an optional cover made from, for example, a large tin can. The fact is that the motor gets into a dusty environment - this dust is formed when grinding dry grain. The engine can become clogged with deposits, and its operation will slow down - a noticeable part of its useful power will be lost.

- Do not use the grinder at maximum speed, trying to grind tons of grain in one go. A large farm in which farm animals are kept in significant numbers will require two or more grain grinders. It is better not to save on equipment, so that it does not fail after a few days, but works for a number of years.

- Use collection containers for grain as large as possible.

- Clean and lubricate the mechanics every three months or six months. Regular maintenance - and planned replacement - requires bearings, without which no electric motor would work.

The listed measures will allow the user to process large volumes of grain without investing extra time in repairs and without stopping urgent work.

How to make a grain crusher from an engine with your own hands, see the video.

The comment was sent successfully.