How to choose a grain crusher for your household?

In a household, it is almost impossible to do without such a device as a grain grinder. The main task of such equipment is to grind grain, and this significantly saves human labor and reduces money costs. There are several types of devices on the market that differ in their structure and have their own advantages. It is recommended that you familiarize yourself with the list of popular models that have already earned the trust of the consumer. A few useful tips will help you choose your own grain crusher according to certain parameters.

Peculiarities

The grain crusher is an economic unit in which you can grind different types of grain crops - peas, wheat, barley and corn. It should be noted right away that the device has amazing performance, even cobs can be thrown into it, with which it can easily cope. Thus, it is not necessary to do unnecessary work, peeling the grains, it is enough to throw everything into the mechanism, and the machine itself will cope with the task. If necessary, you can replace the mesh with smaller holes to make flour from the corn, which is quite convenient.

There are many modern models on the market that are suitable for crushing eggshells and shells. The question is, why is all this required? Well, if the farm has poultry, it needs to be fed with something, and grain is best suited for this. However, it needs to be recycled, so it is difficult to handle without a shredder. The peculiarity of the device lies in the fact that each type of this unit can have its own design.

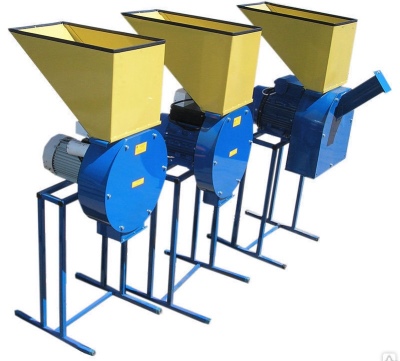

For example, when it comes to home crushers, they are small and easy to use. However, there are also large mechanisms on the market that are installed in agricultural enterprises, where there is a large amount of work.

Despite the parameters, any grain crusher has excellent performance, so it can process a huge amount of raw materials in a short time, which is the main advantage.

Species overview

It is worth studying the varieties of grain grinders, which differ in structure and principle of operation. Each of the options presented has its own characteristics and advantages that should be considered when choosing equipment.

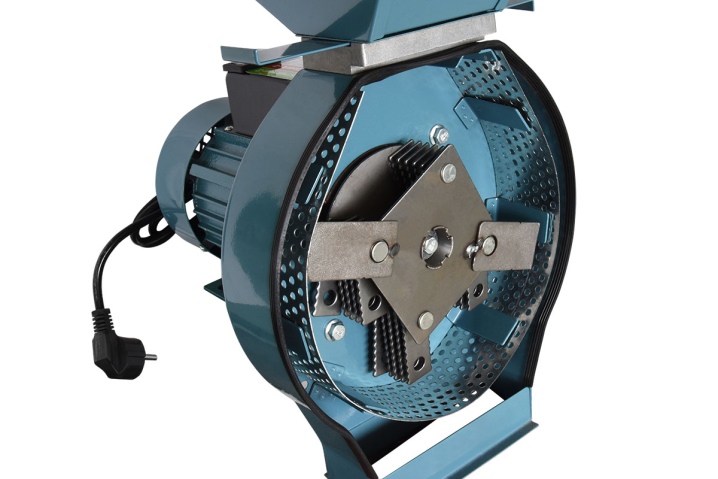

Hammerheads

This device works due to a rotating drum, which has special hammers, hence the name of this type of thresher. The grain crusher is a simple device that anyone can operate, since the design is elementary. At the exit, the mill produces high-quality feed, however, it should be borne in mind that such a unit cannot be used for raw vegetables.

The maximum moisture content of raw materials should not exceed 15%. The equipment works quite noisy, as there are no additional components that would muffle the sound. At the same time, the household device is considered economical and presented in a compact size, therefore it is most often used in small farms. This is the best option for crushing a house at a bargain price, so you can safely consider this type of equipment.

Disk

The design of such a grinder includes hammers that are attached to the discs. These elements are suspended, the main distinguishing feature of the crusher is that there are shear plates inside, which are designed to cut the feed, which secretes juice. The attachment is attached to the drum, making chopping vegetables much easier. Thus, it is possible to produce feed not only for chickens and other poultry, but also for cattle.

Roller

Such equipment can not only crush grain, but also grind raw materials, which is a great advantage. It is worth noting that some units have the ability to adjust the grinding, moreover, they are electric and manual, it all depends on the amount of work that needs to be done. The main element in this type of crusher is the rollers, which have a corrugated surface, and in some they are notches.

Such a device is effective if the grain material is initially moistened. For example, if it is necessary to crush grain, it must be wetted with water or steam, after which it can be fed into the system. This equipment is suitable for working with feed, malt, which is relevant in the production of beer. The device intended for this works on a different principle, since the rollers are equipped with flat teeth, so the feed can not only be chopped, but flattened.

Such a crusher is manual, it has an important advantage - the grain is preserved intact, since only its outer shell is destroyed.

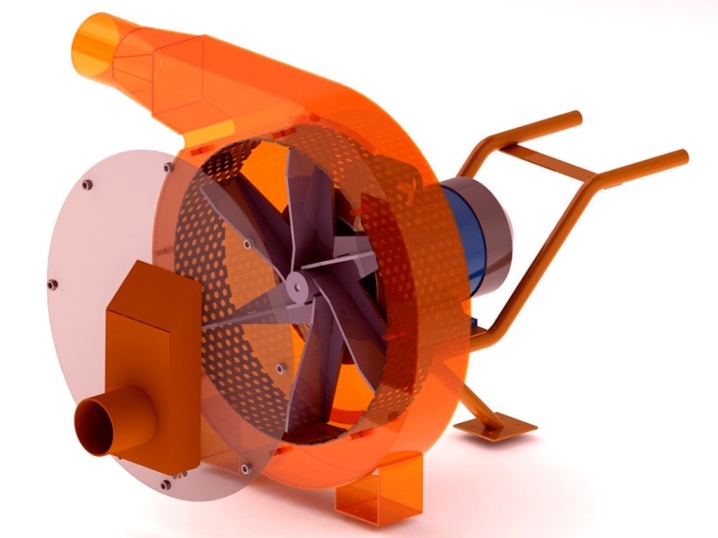

Rotary

The unit is presented in a large size, so it has high performance and power. Often the equipment is installed in large enterprises where a large amount of work is required. Such a crusher will become an integral part of the farm. The device is designed for grinding root crops, grains and grass, the raw material is attached to a rotor that rotates. As for the size of the source material, it depends on the speed, which can be manually adjusted.

There are also mini-grain grinders that can be used in the household. They differ in the type of drive mechanism. Hand-operated devices are easy to maintain, but the work will take longer and require more effort. If you need feed for growing poultry, it is better to use a pneumatic crusher, which can be loaded with corn, wheat and other crops.

Such a device has high speed and performance. Electric mills are in great demand, which are fast and easy to implement. In addition, the unit is presented in a compact size, therefore it often attracts owners of small farms and individuals.

Rating of the best models

The market offers a wide range of crushers from different manufacturers, they differ in quality, engine power, principle of operation and availability of advantages. We bring to your attention the top shredders that have earned the recognition of consumers. In this rating there is a short description of the units and their main advantages are indicated.

One of the good representatives of crushers was device "Chelyabinsk Cyclone 350", which is compact in size and light in weight. Such a crusher makes a sufficiently fine grinding, works economically with high productivity. If you need to prepare food for poultry on a farm, this option is perfect. The crops must be filled from the top, which is a great advantage as there will be no residues. The crusher is rectangular, which makes the movement uncomfortable, but this is a minor drawback. The unit is noted for high power, affordable price and ease of maintenance.

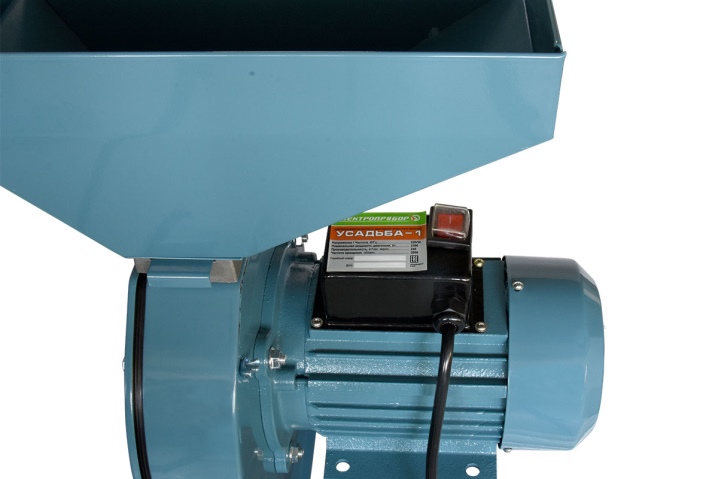

Next on the list was chopper "Three Little Pigs 350"... The package includes a knife and a sieve, this is an economical unit with a hopper, which is convenient to load. The main task of the product is to process hay and grain crops, if desired, cereals can be crushed into small enough, raw materials are laid on top. Lightweight and economical unit became "Farmer IZE-05"which also has an ergonomic design. The design of this model is carefully thought out, so it can be operated in a small enterprise. If necessary, you can change the size of the fraction thanks to the dampers.

Equipment is in great demand in its field "Zubrenok 1350 W", which is made miniature and equipped with additional mesh of different diameters. This is a rotary crusher in which grain or maize is mainly crushed. Thanks to its convenient dimensions, the device can be installed even in the back room. The grain receiver has an elongated shape, which is not always convenient.

Within an hour, you can get about 140 kg of coarse grain, but it all depends on the type of cereal. For personal use, such a crusher is best suited.

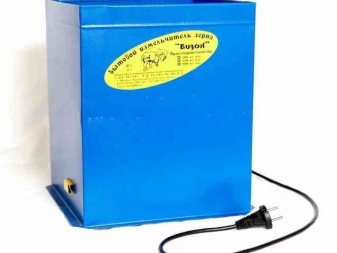

Easy to operate due to the design is the installation "Electromash Bizon-300" with high performance. The machine has an impressive lifespan without interruption. Such equipment can be fed not only grain crops, but even corn cobs or root crops, which will be processed in a matter of minutes. The machine is able to work for 6 hours without stopping, which is a significant advantage. Despite the fact that the equipment does not have a sieve, it has firmly entered the ranking of the best grinders.

Selection Tips

When choosing such a serious unit, it is necessary to take into account a number of factors that may affect the further result. Since the market offers many varieties of equipment that are used in the village, it will be useful to familiarize yourself with a number of recommendations that will help you cope with the task at hand. It should be borne in mind that the purchase of expensive equipment does not always meet expectations, first of all it is necessary to pay attention to the technical characteristics.

In order to select a crusher that will do its job perfectly, it is important to ensure the strength and power of the machine. Therefore, first, study the material from which the equipment is made. The thickness of the steel plays an important role as it affects the rate of deformation of the unit. The next criterion should be the size of the grind. Decide what exactly you are going to grind, for whom the feed is intended. When it comes to poultry farming, a hammer crusher is the best choice, but a rotary device is suitable for cattle.

The crushing method is always indicated in the characteristics of the machine. If knives are used for chopping, the device can handle both dry food and root crops. Hammer crushing is not suitable for such tasks. Productivity affects the amount of work done. For large business enterprises, it is necessary to choose equipment that can cope with the load, and can work for several hours without stopping.

Since the feed must be stored in advance for the winter, it is important to ensure that the equipment can handle this volume. As for the dimensions, it all depends on where the grain crusher will be installed, because the units are offered in different sizes. At the same time, it is important to provide free access to the supply of raw materials, the removal of feed. The shredder should be in a suitable environment with ventilation.

Operating rules

During the operation of agricultural machinery, a certain set of rules must be followed in order to ensure the safety and productivity of the work. Raw materials must be fed into the hopper evenly, this will avoid stoppages or jamming of the system. It is important to adjust the crushing speed depending on the type of raw material.The engine must be turned on with an empty hopper so that the chopper will pick up speed, otherwise the motor will overload.

The comment was sent successfully.