How to sharpen an ax correctly?

Axes are used to perform many works, the successful implementation of which largely depends on whether the metal blade is well sharpened. In order to keep the device in order, it is not at all necessary to contact a specialist - you can do it yourself.

Necessary equipment

The device used to keep the ax in shape can differ in structure, complexity of operation, and price. A special sharpener for an ax allows you to solve the issue quickly and without much physical difficulty, but in this case it is important to monitor whether the cutting blade is overheating, and you still have to pay a decent amount. This explains why the grinder is more commonly used by professionals who require it on an ongoing basis. For home use, an abrasive wheel that is fixed at the desired angle is more suitable.

You should also make a stencil to understand what state of the blade you should aim for. To do this, cut the required angle on a small sheet of tin, which is then applied to the cutting blade and drawn with a marker.

At what angle to sharpen?

The angle of the ax at which you want to sharpen it is determined depending on the functionality of the device. For example, if you plan to trim posts or logs, then you need a fairly sharp angle - about 20 degrees. Grooves and tenons, like other tasks requiring filigree work, are performed at an angle, the indicator of which ranges from 15 to 20 degrees. This choice, by the way, will also allow for preliminary processing. As for the bevel of the cleaver, its slope depends on the type of wood being processed.

Generally, the denser the tree, the dumber the slope. A variety of versatile work can be carried out with an ax angle of 25 to 30 degrees. The smaller the angle at which the ax is sharpened, the sharper the blade will be. The sharper the blade, the easier it is to use, but the faster it will fail. In addition, an overly sharpened blade increases the likelihood that it will get stuck in the wood and will have to be pulled out with some physical effort.

It is important to mention that the blade edge can be of the following types:

- oval - suitable for tools with which trees are chopped or partially trimmed;

- razor - allows you to perform more delicate work, for example, a figured cut;

- wedge-shaped - it is considered universal, it makes it possible not only to chop wood, but also to remove the upper layers of wood and even slightly level the surfaces; it is an ax with a wedge-shaped edge that is recommended to have in the household.

Sharpening process

In order to properly sharpen an ax at home, it is important to choose the right way to process the cutting blade. It will depend on the following factors:

- what kind of wood they have to cut - in this case, the stiffness of the fibers, and their twist, and their other parameters must be taken into account;

- it is important whether the wood is wet - then the blade will need to go deeper;

- the type of carpentry is taken into account - whether the ax will be used for felling trees, chopping wood or cutting logs;

- the stronger the steel from which the cutting blade is made, the more difficult it will be to sharpen it by hand, but the result will be more durable;

- the width of the chamfer is always taken into account - this indicator should allow the blade to plunge into the material being processed;

- the angle at which the sharpening is carried out is important.

During work, it is important to follow several safety rules so as not to harm your health.

Protection is important - not only of the eyes and hands, but of the whole body. Moreover, it would be good to wear a respirator when working with an electrical device. The entire workspace should be freed from unnecessary problems, leaving only the ax itself and the devices required to sharpen it. Finally, it is important to exclude the presence of people nearby who are not taking part in the work.

Grinder

Sharpening an ax with a grinder is not recommended by professionals the following reasons:

- the procedure is dangerous and difficult for people with low physical fitness;

- the metal heats up quickly, which leads to a deterioration in its quality characteristics.

Bruscom

In addition to a measuring bar or protractor, a set of abrasive stones, differing in their grain size, rough cloth, water, as well as a leather belt as a rule, are needed. Using a measuring bar allows you to find out at what angle the sharpening will be carried out. This device will need to be made with a bevel corresponding to the angle of the planned sharpening. The tool is placed on a straight, stable surface, such as a table or stool, after which the blade begins to be cut with a bar. In this case, the stone moves along a curve, creating half rings.

It is necessary to hold the bar at the angle of the required sharpening. Thanks to a stone with a coarse grain, it will be possible to provide the required slope and width of the chamfer. The second side of the cutting blade is processed in a similar way. At the next stage, sharpening occurs using a bar with an average grain size. Lastly, using the smoothest stone, all burrs are removed and all uneven fragments are corrected.

If everything is done correctly, the bevel will be evenly smooth tactilely. After straightening on a leather belt under tension, you can complete the job. Residual debris or dust can easily be removed with a piece of cloth. By the way, during the work, it is periodically recommended to moisten both the stones and the ax.

If sharpening is done for the first time or the blade is too dull, it is worth sharpening by separating it from the handle.

On a grinder

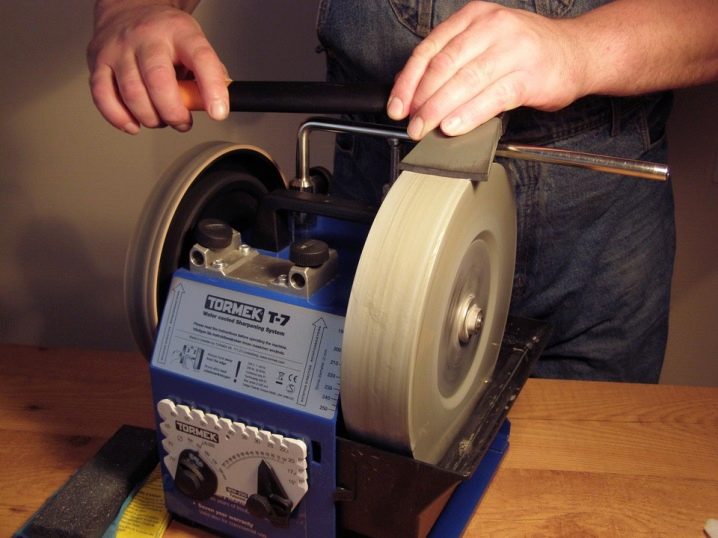

Specialized machines are usually used by professionals. In addition to the electric drive, they are equipped with a device that allows you to sharpen axes at a certain angle. Direct sharpening is carried out using an abrasive disc. Since the ax is mounted on a cylinder, it will not move from side to side and disrupt the workflow. In addition to the machine itself, for sharpening it is also necessary to prepare a hand sharpener with two sides, a marker, a polishing agent, an inclinometer, as well as the master's protection: gloves, glasses, closed clothes and shoes.

First of all, the chamfer is covered with a marker, then the ax is fixed on the machine. The point is brought to the grinding wheel, and the required cutting angle is selected using the sharpening angle. To check the circle, you need to turn it yourself and see if the paint has worn off where the blade and the stone contact. Ideally, they should disappear completely. When finished with the settings, you can turn on the sharpener. The chamfer is processed until all the irregularities disappear, and everything is brought to mind with a hand sharpener.

After the ax is removed from the machine, the leather or felt will need to be treated with a polishing paste and the same should be done with the bevels of the point. The sharpening procedure is completed with an anti-corrosion solution.

File

If you wish, you can also use a file to sharpen an ax with your own hands, having done everything on emery. Completing the task will require the following tools:

- rust converter;

- wire brush;

- sandpaper of three types (from hard to velvet);

- polishing paste;

- a piece of cloth;

- locksmith vice;

- files;

- measuring ruler;

- grinding wheel with two working sides;

- a fragment of technical wax;

- mineral oil for lubrication.

Important! The face must be protected either with glasses or with a full-fledged shield.

First of all, the blade is cleaned from the effects of corrosion and any contamination. Then sandpaper is passed over it. Further, sanding is carried out using a medium-grained sandpaper. The next step is polishing with a special paste. The ax is fixed in a vice or between the squares, with the help of a file, sharpening of the chamfer begins. The surface of the abrasive must be moistened with water.

It is important to bring this figure to 12 millimeters, which is suitable for an angle of 25 degrees. The blade goes in a circle, alternating sides. A felt cloth is used to remove debris and dust. Periodically wetting the blade, it will need to be "brought to mind" with the rough and soft side of the double-sided sharpener. The treatment is completed by coating the blade with an anti-corrosion solution.

Frequent mistakes

Experts have identified several of the most common errors inherent in the process of sharpening an ax.

- Overheating of the processed material, as a result of which its structure changes, which means that quality indicators, for example, stability, deteriorate. As a result, the ax begins not only to cut worse, but also runs out of time faster. However, it is not difficult to avoid this problem - it is enough to moisten the abrasive all the time during operation either with ordinary water or with a special liquid intended for this. As for the ax itself, it should be periodically dipped in water for cooling.

- Sharpening the ax on the grinder, when the latter is held in the hands. In this case, the cutting blade will move from side to side and cause permanent damage. In addition, the cutting blade loses its durability.

- Sharpening an ax on outdated equipment, in which the grinding wheel is out of order. The resulting relief formations, the relief of the abrasive surface, will not allow the procedure to be carried out qualitatively.

- A person strives to get the job done as quickly as possible. Sharpening an ax is not a matter in which haste is possible, because everything must be done carefully and calmly. In addition, it is always recommended for beginners either to contact specialists for the initial implementation of the procedure, or to carefully study the freely available materials.

- Improper storage and operation of the ax itself. Ignoring some rules leads to the fact that sharpening will be short-lived. The device must be stored in a case made of dense material, for example, genuine leather. During processing, the cutting blade should be periodically coated with oil or water, or similar solutions. To complete the procedure, it is worth coating with wax and machine oil to protect against corrosion.

How to sharpen an ax correctly, you will learn from the video.

The comment was sent successfully.