How to make a snow blower from a trimmer?

A snow blower is an automated mechanism designed to remove snow from open and hard-to-reach areas. It is presented in various modifications, differing in power parameters, the amount of energy / fuel consumed, design and others.

The garden trimmer is a gasoline / electric tool designed for mowing grass and small shrubs in the garden. The line of their production is represented by models that imply use in manual and semi-automatic modes. The design of some devices allows you to modify them in such a way as to operate this tool as a snow plow.

How to make a snow blower from a trimmer - we will tell in this article.

Benefits of a homemade snow blower

It may be necessary to create a snow blower from a trimmer when the first is available, but the second is needed. The modification will allow the same gardening tool to be used for different purposes.

The main advantage of a homemade snowplow is its low manufacturing cost. There is no need to purchase a specialized unit. Homemade and / or purchased accessories are used to reorient the tool. Not every mower is suitable for converting into a snow blower.

Before starting this process, you should make sure that it is advisable. To do this, it is necessary to evaluate the characteristics of the existing automatic streamer.

Which trimmer should you choose?

To make a snow blower, you need a fairly powerful unit. It can be made from an electric trimmer or a petrol cutter. The latter is often preferred.... The reason for this is the technical characteristics of the former. The electric motor of such a device is designed for certain power loads. Inappropriate use can lead to its early failure.

The gasoline engine, due to its design, can operate under a wide range of loads.

An important role is played by the design of the boom, the hand-held mower, designed to transmit torque. Some of them are curved tubes. In such "Arcs" transmission is carried out by means of a flexible cable. This engineering solution is not suitable for using the unit for snow removal.... The cable transmission will not cope with the load, which will increase significantly during the removal of snow.

A suitable trimmer design option would be one that provides a direct transfer of torque from the engine to the working unit.

In such modifications, the driving energy is transmitted through the propeller shaft. It is significantly ahead of the cable equivalent in terms of technical indicators.

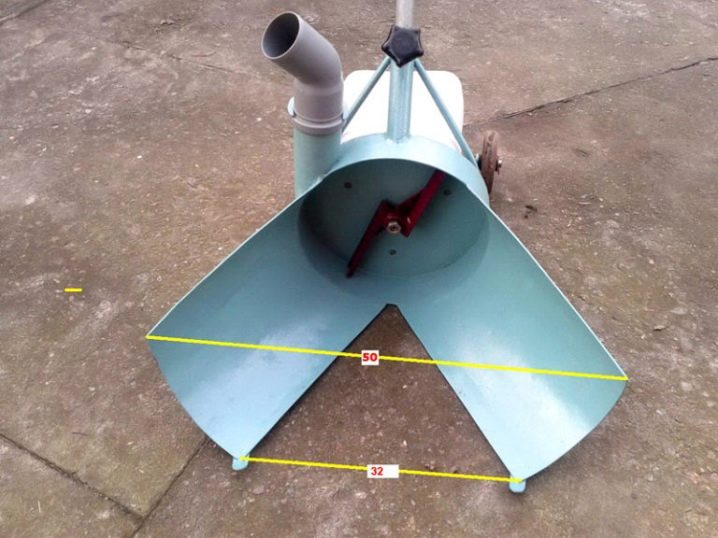

For the manufacture of a snow blower you can use a wheeled lawn mower... A model equipped with two wheels and a rotating working element located in the front of it will do. A mower of suitable configuration is shown in the photo below.

The four wheel model is not suitable for converting into a snow blower.

Tools and materials

The set of tools required to make a snow blower may vary depending on the chosen path to achieve the goal.Some homemade modifications are not reusable, while others are designed for permanent use.

Minimum set of tools:

- Bulgarian;

- drill and drill;

- welding machine;

- hammer, pliers, wrenches and others.

LBM is necessary for cutting out the necessary parts from metal and their subsequent processing: grinding, cleaning, sharpening. Drill - for drilling holes for fasteners: bolts, rivets, clamps. An inverter is needed to weld all structural elements together.

List of materials:

- sheet metal (thickness varies depending on the chosen design);

- pipe sections: metal, plastic;

- bolts, nuts, washers;

- metal clamps.

The drum body, blades and cleaner bucket are formed from metal sheets. The pipe is necessary for arranging a directional snow discharge. Through it, the jet is ejected. Fastening threaded accessories are needed to fasten parts of a collapsible structure. Clamps can be used to attach the harvesting attachment to the trimmer bar.

How to make?

Making a snow blower from a petrol trimmer with your own hands does not imply reworking the design of the mower, but comes down to making a nozzle. Let's consider an example of the simplest design of this removable element for a gasoline trimmer.

Before starting the workflow, it is necessary to draw up the corresponding drawings. They must take into account the dimensions of all parts and how they are connected to each other.

Drum body manufacturing

The drum body is a metal cylinder with a diameter greater than its height. The size of the diameter and height of this "Box" determines the amount of snow that will be thrown to the side. The body should not be too largeas this could overload the trimmer motor.

The drum is made by cutting out a circle of the required diameter from a sheet of metal and welding a rim to it. This collar can be made from the same sheet metal by cutting a tape from it, the length of which is equal to the circumference of the circle. Welding is carried out in a pointwise way to avoid deformation of the workpieces due to the high heating temperature. After tacking the parts by welding to one point, the side is bent along the edge of the circle, the point fastening is repeated. As a result, you should get a kind of round "Bowl" with a side.

Its optimal diameter is 30 cm, and the height of the side is from 5 to 8 cm.

A hole is drilled in the center of the bottom of the "Bowl", which is intended for attaching the drum to the gearbox housing for the transmission of rotation to the trimmer shaft. The hole diameter is several units larger than the shaft diameter - their contact is excluded. The drum is permanently attached to the gearbox. To do this, elongated nuts are welded to the gearbox housing or the fixing holes in the gearbox itself, if any, are used. In the bottom of the drum, holes are drilled, located opposite the equipped fasteners on the gearbox. By aligning the holes with the mounting points on the gearbox, you can screw the drum to the trimmer head.

To keep the drum body firmly on the trimmer, a stop is welded to the back of the first. This element is a jumper connecting the drum with the tube-body of the spit cardan. The jumper is attached to the tube with a clamp.

Screw making

A disc is cut out of a sheet of metal, the diameter of which is 2 cm less than the diameter of the drum. A hole is drilled in the center of the disc with a diameter equal to the diameter of the trimmer shaft + 0.5 mm. 4 blades are welded to the disc with an edge. Their arrangement is criss-cross.

The blades should not touch each other in the center, leaving a free hole in the disc.

Disk with blades - the propeller rotating on the shaft should not come into contact with the bottom of the drum body... To do this, a nut is first screwed onto the shaft, then a disk is put on, which is fixed with another nut. The height of the first nut must be sufficient so that, resting on it, the screw is not far enough from the bottom of the drum and the heads of the bolts that attach it to the gearbox.

In the upper part of the drum (from the side of the trimmer motor) a hole is cut with a diameter equal to the diameter of the snow pipe. This pipe is welded to the edges of the hole and the weld seam is carefully welded. The snow deflector must be directed away from the machine operator. The optimal angle of inclination of the pipe is selected, depending on the characteristics of the terrain on which the snow will be removed. It must be sufficient for the snow jet to reach the desired length.

Front end and bucket

The front part of the drum body is half covered with a metal plate. Its fasteners must provide for the possibility of installation / removal. This is necessary in order to be able to periodically clean the drum from frozen snow and to remove the nozzle from the trimmer. To do this, "ears" with holes are welded to the drum body through which the face plate can be bolted. Holes must also be made in it, located opposite the "ears" of the drum.

The bucket, designed for picking up snow masses and feeding them to the screw, is made of the same metal as the rest of the parts. It is a scoop plate welded / bolted to the bottom of the snow plow body. Its leading edge must be sharpened unilaterally. This is necessary to improve penetration into frozen snow.

The bucket can also be detachable.

Additional Information

All nut and bolt connections should be fitted with washers or spring clips (if necessary). The propeller blades are rectangular with rounded corners.

When operating a brushcutter snow blower, it is important to take breaks and rest the tool.

For information on how to make a snow blower from a trimmer, see the video below.

The comment was sent successfully.