All about stone engraving

Stone engraving is one of the types of stone products processing, in which a certain image is formed on the surface in the form of a pattern, drawing or text.

General description of technology

To have an idea of stone engraving, it is worth considering the technology of its creation.

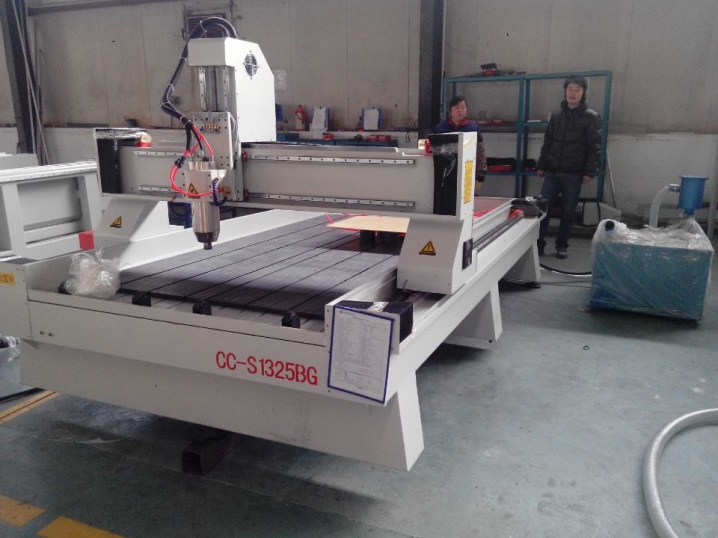

- The use of CNC machines assumes maximum automation of work. At the same time, high artistic skills or special skills are not required from the employee. In this case, the image is formed by using the graphics editor Adobe Photoshop.

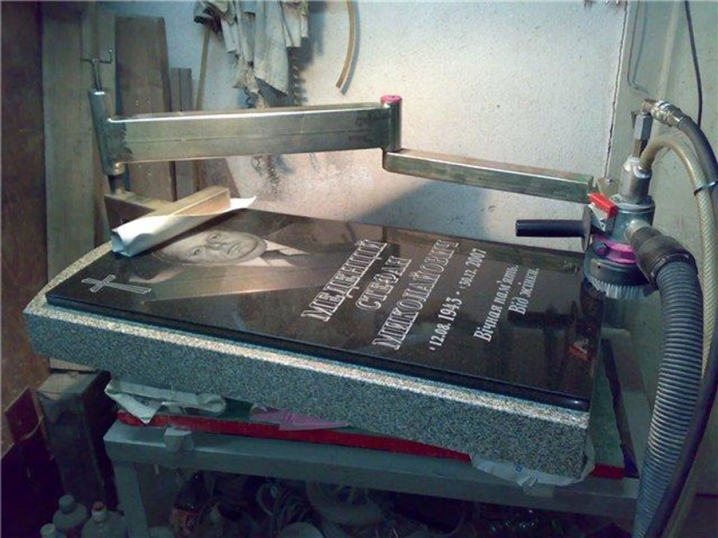

- From the point of view of direct interaction with the material, percussion technology is used. In this case, the pattern is formed by applying micro-chips to the rock surface. Efficiency, accuracy and quality of work in this case depends on the characteristics of the equipment itself.

- The processing area depends on the working areacaptured by the machine.

- Sometimes stone carving is done by hand. True, this technology is considered outdated and is becoming less common. It is most often used in small workshops or at home in the case when the stone cutter works according to folk technologies, while maintaining the authenticity of the work.

Views

Today there are certain types of stone engraving.

- Manual... It is performed by craftsmen who have a high level of artistic skills. They are extremely necessary, as in this case the master works with small teeth and chisels. In order to apply a pattern in this way, it is necessary to make notches in manual mode, after drawing the pattern on the surface of the stone blank.

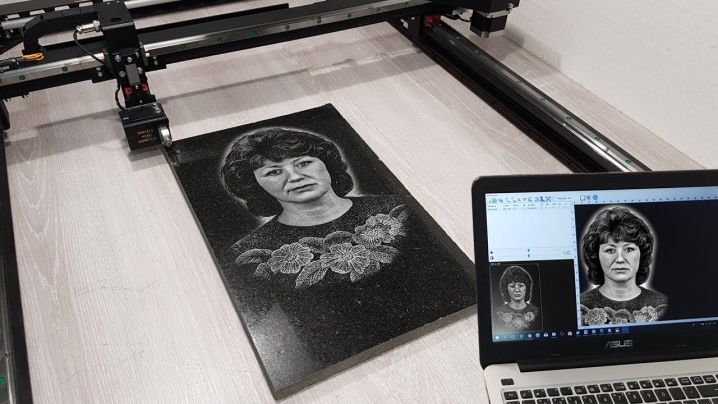

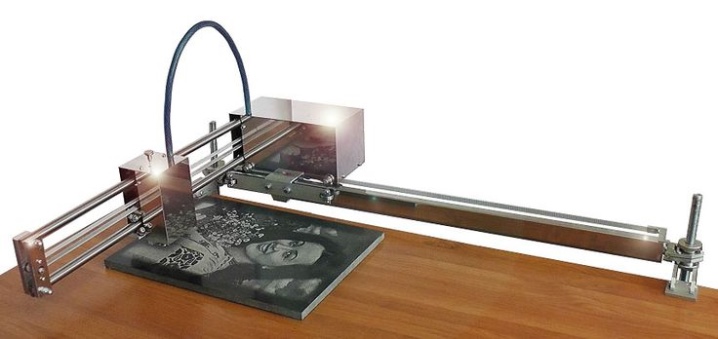

- Laser option engraving a stone product is an almost completely automated option, when a drawing, pattern or any text is formed on a stone surface using a precisely focused beam. In this case, special laser machines are used. Most often they work on the principle of a carbon dioxide laser. In this case, the focused beam can have different power of work. This is an important parameter that can be adjusted. In different operating modes of the laser machine, either micro-chips can form on the stone, or the image will be applied by fusing stone structures.

- Another variety is engraving by milling.

- Similar types of work can also be performed. with the help of machines with numerical software by the impact method.

- Sandblasting machines are sometimes used, which release a jet of sand at a high level of pressure. Thanks to this pressure, the stone structure is scratched, and this or that image is formed on it.

The choice of the type of engraving depends on the tasks facing the master, as well as on the possibilities of the engraving workshop.

Choosing an engraving device

To choose the right engraving machine, you need to follow some rules.

- Determine the working area of the device. It must correspond to the goals pursued by the master. That is, if you plan to work with large enough surfaces and you need to apply a pattern on them, then the working area of the machine should be as large as possible.

- The second parameter, which is extremely important, is the type of the machine itself. There are fundamental differences between the types of machine tools.So, for example, a CNC machine requires a specialist who can provide the correct program setting, deep and versatile preparation. But if a shock-engraving device is chosen, then it will be necessary to stock up on consumables. In this case, these are needles, with the help of which images are applied to the stone surface. But for milling machines, it is necessary to prepare discs of different sizes. It is they that are important for the drill, since with their help the image is applied.

- The speed of engraving is also important.... This affects performance. Therefore, if the workshop is large enough and has a large number of orders, then the machine must ensure the application of a certain area of the pattern per unit of time.

- It is also important to consider the cost of the device and the cost of its maintenance.... Depending on who manufactures the product (brand awareness and country of origin), the price will be formed.

- The cost of engraving on certain equipment is also important.... It is important to take into account that on a laser machine these are the highest prices for receiving the product. But at the same time, the speed of work here is also the highest among other devices. Therefore, when choosing equipment, the owner of an engraving workshop is guided by the ability of the population to order finished products at one price or another.

Thus, it becomes clear that the correct choice of machine for engraving is an important preparatory stage for the work of an engraver.

Where is it applied?

It is worth noting that this method of stone processing has existed for almost as long as humanity lives on earth. Even in the most ancient times, people applied drawings on the walls of caves. Gradually, the technology changed, more and more devices appeared. Got some experience in stone processing, including drawing.

Today, stone engraving is performed most often using rocks such as:

- gabbro - these are igneous rocks, which are distinguished by the inclusion of pyroxene and plagioclase;

- well known to all granite;

- marble - white, pink or dark;

- dolomite marble;

- magmatic basalt;

- dolerite or the so-called complete crystalline fine-grained igneous rock.

Based on what material is chosen for stone work, engraving can be performed for different purposes.

- For ritual purposes... Most often, gravestones and monuments are made of granite, marble, and other basalt rocks. They can be different - from the simplest to the most complex. Moreover, in one case, it is just a plane with a pattern applied, while in other versions, these are complex artistic constructions. Today's new technologies make it possible to apply any image from any photograph to the stone. This further enhances the value of engraving in the creation of monuments.

- The second use of stone engraving is to create objects. for the urban environment... Quite often you can see granite slabs on which certain inscriptions are applied. They can decorate monuments, building walls, or any other object.

- Laser engraving can be applied for creating various plates, signs or nameplates.

- Engraving work using other materials is less commonly used. Today's high-tech equipment makes it possible to do this with success. So, for example, using a sandblasting or laser machine, you can engrave jewelry, umbrellas, crystal, glass, plates, medals, cups and other products. Thus, commemorative inscriptions are performed, which are relevant in this case, when objects are presented in order to preserve memory.

All this is an additional source of income for engraving workshops. This fact is important to consider when the main goal is to increase the level of profitability.

Therefore, when choosing equipment for such work, it is worth considering the promising possibilities of this direction.

Watch a video on the secrets of granite engraving.

The comment was sent successfully.