Motoblocks: types, description and selection

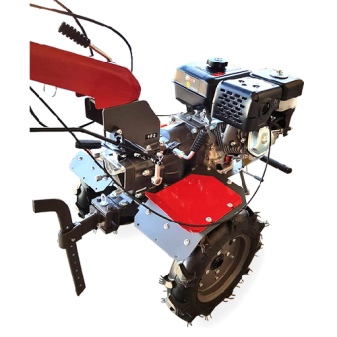

A motoblock is a universal technical means, the design of which provides for a uniaxial chassis. On the other hand, it is one of the small tractor varieties. Used equipment for agricultural work and not only, for example, with its help you can quickly and efficiently clean the area.

What it is?

The name itself began to be used in Russian in the 80s, earlier this technique was known as a pedestrian tractor or single-axle tractor. Its description has remained practically unchanged since that time. It was not very convenient to speak, so they decided to replace it with one word. A walk-behind tractor is a vehicle, and at the same time an agricultural tool used to prepare the soil, not only for planting.

Gardeners and summer residents use a walk-behind tractor to mow grass and even trim small shrubs. Modern manufacturers use gasoline and diesel engines, as well as additional attachments, which can significantly expand the scope of operation of such small equipment.

Depending on the type of soil and the cultivated area, the walk-behind tractor is selected so that its power and other technical characteristics are suitable for the user.

Additional attachments are offered to the technique, which allows you to perform a wide range of tasks. All walk-behind tractors differ not only structurally, but also in weight, dimensions, type of power unit. The working width and working depth depend on the type of attachment used. If we talk about the device of walk-behind tractors, then there are few differences between them.

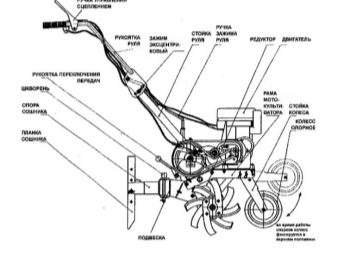

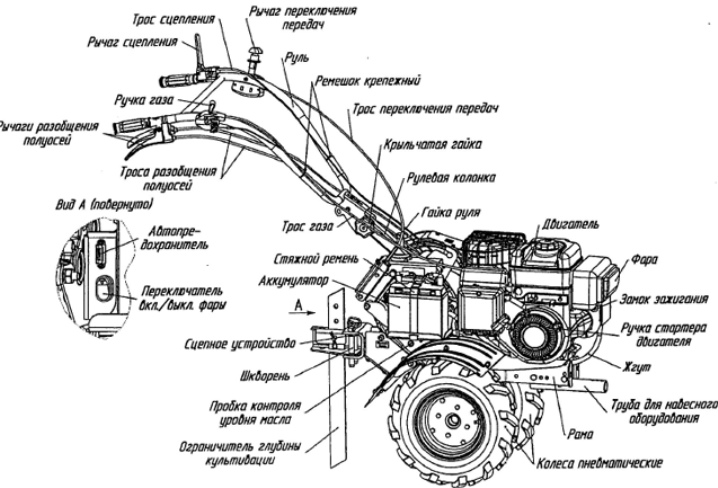

In the basic design, everyone, regardless of type, has:

- chassis;

- motor;

- control system;

- transmission.

The motors are installed in the classic version - internal combustion. As a rule, this is a 4-stroke power unit.

Motoblocks running on diesel and gasoline differ not only in fuel, but also in weight, since the former are much larger in weight.

The technique that is used in small areas runs on gasoline. Diesel units have more power, so they are best suited for areas up to 50 acres. However, they have their drawbacks - diesel-powered units cannot be operated in winter. Gasoline engines can operate smoothly in ambient conditions from -30 to + 40 ° C. The main task of the motoblock transmission is to transfer energy from the motor to the wheels. Due to it, the speed of movement is also determined. The frame, with wheels firmly attached to it, is the chassis.

Governing bodies consist of such components as:

- steering column;

- gearshift thrust;

- a lever through which the gas is regulated;

- clutch.

Views

In order for the user to purchase exactly the walk-behind tractor that will not disappoint him later, he should study in more detail the types of this small-sized equipment.

By weight and power, all units can be divided into several groups:

- lungs;

- medium;

- heavy.

The owner of a small plot of land can purchase a light walk-behind tractor, which will differ in its affordable cost. As a rule, this technique does not exceed 4 liters. with. This suggests that the depth to which the cutter will plunge into the ground does not exceed 20 centimeters.The weight of such equipment is up to 30 kilograms. The small size makes it possible to say that this technique is quite maneuverable in narrow areas, but it is too light if used without weights.

Semi-professional walk-behind tractors have a little more weight and dimensions, on average they weigh 60 kg.

This technique is no longer so mobile, since it is not easy to lift it and load it into the trunk of a car. The functionality of such motoblocks is extended, they can dig out potatoes. Power reaches 6 liters. with., and this is enough to make a small snow blower out of equipment.

Professional walk-behind tractors weigh up to 100 kilograms. The advantage of such units is that they perfectly withstand heavy loads. It is possible to work with equipment on heavy soil, since the weight of the structure is sufficient to immerse the cutter to the required depth. The power of this type of motoblocks reaches 13 liters. with. They are also used as a small vehicle, if you use pneumatic wheels and a trailer.

All equipment of this type can be divided according to the type of engine:

- gasoline;

- diesel.

Each type has its own advantages. Self-propelled gasoline walk-behind tractors for summer cottages are lightweight, do not work as noisy as diesel ones, and do not depend on weather conditions. When using them, the vibration on the steering wheel is practically not felt by the user. The owners have repeatedly noted that it is much easier to take care of such equipment.

Despite such a number of advantages, diesel ones also do not lag behind in popularity, since they are more economical, there is the possibility of built-in cooling.

Due to their high weight, these machines show excellent stability on uneven loamy soil. Both those and other garden tillers can be supplied with headlights, so you can use the equipment at night. If the old-style manual equipment was used only to create beds, then the new generation garden equipment was used for plowing the land, cleaning, cultivating and transporting goods.

Dimensions (edit)

Such an indispensable assistant in the household, like a walk-behind tractor, is available for sale in various sizes. The equipment can be medium in size, there are small, compact models and those with a rather large plowing width, therefore, such equipment is equipped with a powerful and reliable motor. The length of the motoblocks can vary from 58 to 140 centimeters, the width is from 40 to 62 centimeters, and the height is 100-130 cm.

For more expensive models, you can decrease or increase the length of the handle, this value ranges from 80 to 120 cm. This feature makes the control process easier and more convenient, since any operator can adjust the height of the steering wheel to their individual growth parameters.

The track width created by this technique varies from 35 to 54 centimeters, while the width of the cultivator is 100-220 cm.

Motoblocks also differ in wheel diameter. This parameter is in the range from 42 to 74 centimeters, while their width can be 10-24 cm.On average, a typical walk-behind tractor has a length of 174 cm, a width of 66 cm and a height of 128 cm.At the same time, a cultivator is 120 cm wide, a track of 32 cm with the same wheel diameter. If we talk about the turning radius, then with a ground clearance of 14 cm, it should be 110 cm. The mass of the equipment in this case will be about 98 kilograms.

Specifications

The better the technical data, the more possibilities the walk-behind tractor has. When buying such equipment, the user should pay attention to:

- motor;

- speed;

- transmission;

- clutch;

- control;

- the weight.

The number of speeds depends on how many gears the manufacturer has provided in the design of his walk-behind tractor.

In working order, such equipment can move 2-4 kilometers per hour.If this is not enough, then the user should think about it and buy a 3-speed unit that can reach speeds of up to 15 km / h. There are also super-powerful models on the market, they accelerate to 30 km / h. Each manufacturer equips its equipment with the motor that, in its opinion, is best suited in this particular case.

In addition to the fact that the engine can be gasoline or diesel, they are also:

- two-stroke;

- four-stroke.

Two-stroke power units were used in old models, in modern ones you can often see a four-stroke engine in the design. The power can be from 5 to 12 hp. with., there is a cooling system, for light equipment it is air, for heavy equipment it is liquid.

The engine is started with a manual starter or, if the model is expensive, with an electric starter, therefore, in addition, a battery and a generator are installed in the design. The clutch can be single-disc or multi-disc, sometimes in the form of a belt drive. On heavy walk-behind tractors, the first two types are used, since they are more reliable. No less important than the clutch and the engine in this type of technology is the gearbox.

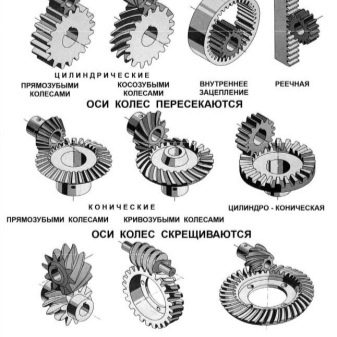

There are many of them, and the manufacturer himself decides which one is best to use, they can be:

- chain;

- gear;

- belt.

Among them there are non-collapsible and collapsible models. The former cannot be repaired in the event of a problem, so the user has to purchase the entire unit, but experts say that this is pointless, and it is easier to buy new equipment. The fact is that a non-cushioned motor is installed in the kit for a non-separable gearbox, and it has a limited resource of work, which, as a rule, is not more than that of a gearbox. In this case, the engine will also have to be changed, and it is 40% of the cost of the walk-behind tractor.

As for the gears, when moving forward, there can be from one to six, and backward - up to two.

The ability to successfully turn and maneuver is provided by a mechanism that is designed to disengage the differential or one of the wheels. To drive the attachment in action or activate the work of the cutter, a power take-off shaft is provided in the design. It can be one or two shafts, sometimes it is a dependent system, and sometimes it is independent. With a dependent system, the movement of the attachment begins after the clutch is engaged, and with an independent system, the energy comes directly from the motor. If necessary, the user can adjust the distance between the wheels. This changes the track width. If you plan to work on difficult ground, then the mass of the walk-behind tractor, if it is not a heavy weight, will have to be increased.

For this, a special ballast is used.

You can equip the walk-behind tractor with another pair of lugs, then the attachment will be better immersed in the ground. If we describe the control system in more detail, then in modern models manufacturers have provided an anti-vibration system and height adjustment. Thanks to this, it became more comfortable to operate the walk-behind tractor. All controls are located on the steering wheel, from here the operator can switch gears and clutches. As for the weight of motoblocks, the maximum is 200 kg.

The design of the equipment under consideration consists of the following main components:

- control system;

- launch system;

- engine;

- transmission;

- chassis;

- aggregation system.

One of the worthy representatives of motors that are installed in the design of walk-behind tractors is a gasoline 4-stroke power unit. Products from Honda and Subaru have proven themselves very well. The thing is that they are better adapted to the technique of this format than others. The crankshaft is in a horizontal plane, but this is not the only advantage of motors from these manufacturers. The combustion chamber is compact and has an increased compression ratio.As a result, such units demonstrate economical fuel consumption.

Recently, the electronic starting system has become more and more popular.

If the walk-behind tractor is large and heavy, then starting it from the hand is not so easy, since at the moment of turning the crankshaft there is strong compression, for this reason the engine does not pick up speed and stalls. The easy start system helps a lot, when a special mechanism is located on the shaft, which is necessary to open the injection valve at the moment the crankshaft turns, thereby reducing the compression.

If the user has the opportunity, then it is worth buying a walk-behind tractor with an electric starter. The engine starts in a matter of seconds, just turn the lever. There are also such models, the design of which provides for two launch systems, and in this case, the manual one is the insurance system.

On sale you can find motoblocks with different types of transmission:

- toothed;

- gear-worm;

- belt-toothed-chain;

- hydrostatic.

If we talk about the classics of the genre, then in this case we are talking about a gear transmission, in which only a cylindrical or bevel transmission is provided. Most often, this type is used on heavy equipment, it is distinguished by the presence of a reverse. The clutch acts as a separate control element, and the crankshaft is horizontal in such a way that it stands perpendicular to the axle located on the drive wheels. On walk-behind tractors with such a system, there is always a shaft responsible for adjusting power.

In the design of light equipment, there is a gear-worm transmission. It is characterized by the presence of two gearboxes, one upper gear and the other lower worm gear, hence the name. The crankshaft stands vertically, there is also an automatic clutch responsible for the clutch, in some models and an uncoupling one. The manufacturer can provide for the installation of the mower a power take-off pulley from the first gear reducer. It should be noted that such a transmission is compact.

Special attention is paid to the belt-toothed-chain transmission, in which the rotation of the shaft located on the gearbox is carried out by the power unit through the belt drive.

She, in turn, fulfills the role and cohesion. In one crankcase there are chain and gear drives, and the use of the second made it possible to make the agrotechnical clearance more. The crankshaft is located in the horizontal plane, thus, relative to the axis of the driving wheels, it is parallel. In this case, you can make a power take-off, for which an additional stream is provided in the transmission design, that is, a beam extending from it.

The belt drive in some models can be used as a reverse. The gear reducer can stand in one of two options:

- two-stage;

- single stage.

The transmission, in the design of which a volumetric hydraulic drive is provided, is called hydrostatic. Power from the motor is transmitted through the movement of fluid in a closed volume between the hydraulic motor and the displacers. Among the advantages, one can single out the absence of steps during regulation, layout capabilities. Such a system is used in the design of domestic and foreign motoblocks. The wide profile has made this transmission very popular.

The technique demonstrates greater productivity, since there is no stepped gear shifting, the speed changes faster, the traction effort is greater for the walk-behind tractor. All this is extremely important when operating equipment in difficult conditions. Among the disadvantages is a short service life with a large weight and high cost. Speaking about the device of the walk-behind tractor, one cannot fail to mention the aggregation system, which is necessary for the coupling of equipment with additional equipment.

In motor-cultivators, all tools are placed on the drive axle, the difference between walk-behind tractors is that the tools are mounted on a bracket.

Since during the operation of the walk-behind tractor, the operator has to follow it, the control system should be located conveniently so that you can easily switch speed and gear. The control is carried out by means of steering rods, to which the manufacturers have transferred the controls. The levers that are responsible for the power shaft, the carburetor flap, are often located specifically on these nodes. There is one more difference between a light walk-behind tractor and a heavy one, in the design of the former there are no brakes, in the latter they are on the right bar, in rare cases elsewhere.

When buying a walk-behind tractor, you should consider its performance. For 20 acres, an engine power of 3.5 liters is enough. with., while the width of capture can be up to 600 mm. When it is required to process 60 acres of land, the walk-behind tractor must already meet other requirements, namely: have up to 4 liters. sec., with a working width of 800 mm for soil cultivation. Processing a plot with an area of up to one hectare will already require a walk-behind tractor of greater power, up to 6 liters. with. To increase the productivity of the equipment, the working width of the attachment should be 900 mm. Large areas, up to several hectares, can also be processed with a walk-behind tractor, only it must have a motor with a power of up to 13 liters in its design. with. and a ground coverage of 1000 mm.

Few of the users understand what a power take-off shaft is.

The fact is that the energy from the motor is transmitted not only to the wheel axle, but also to the milling cutter, due to which it begins to work. This process is supported by the power take-off shaft, which can stand in front of or after the clutch. There are fundamental differences between these two options. For example, if it is in front of the clutch, then rotation is carried out when the walk-behind tractor is standing and moving. In the second, work is carried out only at the moment when the equipment is moving.

The undercarriage is increasingly attached directly to the transmission with wheels. Such a unit is characterized by stability and reliability, at the moment of movement the necessary balance is maintained, vibration is less, and the structure is rather rigid. It is best to purchase a walk-behind tractor model that has the ability to change the distance between the wheels.

As for the wheels themselves, they can be either pneumatic or iron. Both pairs are used in different conditions. The former are necessary for driving on the highway, they are attached when the walk-behind tractor is transported to the place of use, or when the technique plays the role of a small-sized vehicle. As for metal, they are necessary when driving on the ground. Provide the necessary traction with the surface, with the use of an additional wheel, you can improve the balance at the time of the task.

Components and accessories

The complete set of the walk-behind tractor can be basic and additional, for the second the user has to spend money. The basic one provides a minimum set of attachments, due to which you can perform the most popular agrotechnical tasks. The plow is necessary for plowing the land. It is used both on cultivated soil and on virgin soil. Such an accessory is equipped with a ploughshare, which is most often made of durable metal.

There is a classification of such attachments, if we take into account the shape of the main element, then such a device can be:

- reckless;

- dump;

- reversible;

- disk;

- rotary;

- combined.

In turn, plows differ in the type of share that is present in the design. On sale you can find screw, semi-cylindrical and cylindrical models. If we take the number of working parts as a classifying feature, then the plows are multi-, single- and double-body.Single-hulls prefer to use due to their low weight, simplicity of designs. Reversible, which are still known in professional circles as swivel or reversible, have a curved feather at the top of the structure, designed to turn the soil when plowing.

This is the ideal solution when tough or virgin soil needs to be cultivated.

Of all the models, the rotary ones have the most complex structure. They can be two-piece or three-piece, it all depends on the number of plowshares present. Such equipment is best used on soft soil, they are easy to assemble, small in size and weight. Double-hulls can be used for processing any type of soil, if it is necessary to cut furrows, huddle crops, destroy weeds. Install similar equipment on equipment with a capacity of 3.5 liters. with. If you have to work on wet ground, then it is worth using disc plows, which, unfortunately, do not differ in a large depth of immersion in the ground.

Reversible plows are ideal for working on difficult soil conditions. The power of the walk-behind tractor should be taken into account when choosing a model of attachments. Dimensions and weight in this case will play a big role. The product has a distinctive feature - the feather is bent at an exact angle and is located in the upper corner. Thanks to this design, the layer of earth is turned over as soon as it rises.

Moldboard plows, in contrast to moldless ones, are used most often in small areas.

They can be plowed, furrowed, or not furrowed. The moldboard attachment not only turns the soil over, but also loosen it immediately. Moldless plows are used in areas with little rainfall. In addition to plows, milling cutters are used that allow you to loosen the soil without turning it over. The depth depends on the speed of rotation and the diameter of the product.

When it is necessary not to plow or loosen, but only to huddle potatoes or other plantings, a hiller is used.

These products are of two types:

- simple;

- disk.

Potatoes can not only be hilled, but also planted and even dug out with a walk-behind tractor. Thanks to this, in a short period of time, it is possible to process a large plot of land without resorting to additional labor. A potato planter is a kind of container that moves on wheels, on one side it has a furrow cutter, on the other - a hiller. When the first one creates a bed, the potato falls into the ground, and the hiller covers the tuber with earth.

If it is necessary to dig up roots, other attachments are used.

It is a simple structure that lifts the ground, the soil is sifted through a metal grate, and the potatoes remain clean on the surface.

You can plant other crops using a seeder:

- tomatoes;

- garlic;

- onion;

- carrot.

All planters differ in design depending on which plants are planned to be planted. But the list of used attachments does not end there either, since it is possible to put a shredder on the equipment in order to crush garden debris and turn it into compost. Helps with cleaning and brush, it quickly and easily cleans the area. Often, equipment with this attachment and a snow blower is used in public utilities. The blade-blade is adjustable and can be adjusted to the required height of snow removal, while it throws it in one direction.

If you want to use a walk-behind tractor as a small vehicle, then you should definitely buy a trailer in the kit. This is a very useful addition, which makes it possible to transport the crop immediately after harvest. Despite the low power of the equipment, it perfectly replaces a larger one like tractors.The total weight that can be transported on a walk-behind tractor is from 300 kilograms to a ton.

It should be understood that the greater the weight of the load, the more power the motor must have.

The user has the opportunity to remove large grass and even cut small bushes with the help of a walk-behind tractor. For this, mowers are used, which are rotary or segment. The former are in many ways superior to the latter. You can not only clean the area, but also harvest wheat, prepare hay. When preparing the latter, it is worth purchasing a turner in the kit, which allows you to reduce manual labor to a minimum.

How to choose?

In order to choose the right motoblock for rural areas in terms of parameters, it is necessary to take into account a lot of points, and this is not only power or dimensions. Good equipment always demonstrates reliability and durability, it comes on sale with rich functionality, while remaining affordable. Among the huge assortment of models, it is not always easy for the user to make his choice.

As with any other technique, the user must take into account the nature of the future work, so as not to be disappointed in the purchase. Power always comes first, when it is not enough, the equipment cannot perform the assigned task with high quality, respectively, the plow or other attachments does not sink into the ground to the required depth.

Power should be selected based on the type of soil being cultivated.

If it is virgin soil or loam, then a more powerful technique is required, which is able to raise such a layer, turn it over and loosen it. In addition, walk-behind tractors that are used as small vehicles also need to be powerful.

Some experts advise paying attention to the manufacturer, because brands that have been on this market for quite a long time produce equipment that has proven itself over time. There are models from Italian, German and even Russian manufacturers, which are worth paying attention to, for example, the Neva walk-behind tractor. Sometimes motors from Honda and Subaru are installed on our domestic motoblocks, which already speaks of the reliability and quality of such units.

If the user wants to almost completely replace manual labor in the country with mechanized ones, then he should overpay a little, but choose a walk-behind tractor, which will have wide functionality. It is very important that it has a differential, power take-off shaft, reverse and other important functions.

If you have to transport equipment over long distances, it is good when this is a high-speed model that demonstrates acceleration up to 30 km / h.

All attention to the offered basic equipment. It is important to know what additional equipment you will need to purchase for additional money. As for fuel consumption, this indicator is not taken into account, since it is at the same level for most motoblocks.

It is not enough just to take equipment with a trailer, experts advise you to familiarize yourself with the features of its operation before buying. If the user is thinking about saving, then he should buy a diesel unit, which will be distinguished by strong noise during operation, as well as the inability to use it in conditions of a sharp drop in air temperature. Gasoline motoblocks can be operated both in summer and in winter, they are relatively quiet, but less powerful.

If you choose a walk-behind tractor, then such that a rotary plow is included in its package. It is due to him that you can not go back to the beginning, but further cultivate the land. When it comes to quality, the furrow created by disc plows is much better than notched plows. On motoblocks of a small mass, hillers are placed in which the working width is not adjustable, which is not very convenient in some conditions.

A universal cutter is always included in the basic package.

In the case when there are large thickets on the site or the soil is too hard, it is necessary to install another one, it is called crow's feet. She collects weeds with high quality, and sometimes even helps the summer resident to cope with pests that infect the earth. If in the design of the walk-behind tractor it is possible to use a trailing adapter, then such a technique becomes no less useful on the farm than a miniature tractor, and does not differ much from it in terms of functionality.

When a V-belt clutch is identified in the design, the user should be prepared for the fact that he will have to constantly monitor and adjust the belt tension. On imported motoblocks, a disc clutch is used, which is more reliable. Much depends on the quality of the gearbox, since movement is transmitted through it from the engine to the wheels or milling cutter. If we talk about practicality, then it is worth choosing a model in which there is a worm or gear transmission, since such structures break much less often. It is good if the manufacturer has provided protection for the gearbox from dust and dirt, and the main elements can be easily lubricated.

Before purchasing, the user must establish the conditions in which the equipment will be used, since the power and design of the walk-behind tractor must correspond to the size of the territory.

- Powerful, professional models with a large weight are ideal for processing virgin lands, since light walk-behind tractors will simply bounce on bumps.

- If the site was regularly monitored, its soil is light, then the walk-behind tractor can also be bought small-sized with a small mass, so that it is more convenient to operate it.

- When it is planned to use the rear equipment most of the time, then the weight of the walk-behind tractor should be at least 100 kilograms. In this case, maneuverability and convenience do not come first.

Operating instructions and documentation

The information that the manufacturer offers to the user in the operating instructions cannot be ignored. To operate low-power motoblocks, you do not need a license to drive on the roads. Documents are needed if the equipment can accelerate to 30 km / h, since the resource of such motors requires the user to have the appropriate skills and knowledge of how to behave in an area where there are other road users. When using lightweight walk-behind tractors, additional weight is often required, since their own weight is not enough for the plow or cutter to sink into the ground for the required distance.

In the process of mowing grass, it is imperative to make sure that the walk-behind tractor does not run over electrical wires or stones.

The area will need to be inspected before proceeding with the assigned tasks. When transporting, it may be necessary to place the front body on the trailer, making sure that the connection is made properly. If this is not done, while the equipment is moving under traction load, the towed equipment may disconnect, respectively, an emergency situation will be created on the track.

It is not so important to buy a powerful walk-behind tractor, but to know how to properly operate and configure it. Most modern models are easy to maintain, it is easy to find components on them, and if necessary, repairs can be carried out at a service center. The first thing that is required of the user is to test the equipment. If an imported power unit is installed inside, then many questions may arise as to what to fill such walk-behind tractors, and what oil should be used. In this case, all equipment of this type works either on a diesel engine, or on AI-92 and 95. Oil in summer and winter will need to be used differently, it is changed regularly, and for the first time - after 20 hours of operation.

If there is not enough experience, then it is better not to do any maintenance on your own, since the technician will only suffer from the inept actions of the user. The oil is drained while hot, the crankcase is flushed, and semi-synthetics are filled in. In some configurations, the manufacturer offers a dipstick to check the oil level.

In those models where the belt is installed, one of the most unpleasant moments of operation is its constant slipping off the pulley groove. The main reason for this is the tension mechanism weakened over time, loss of traction or even slipping. Filmed and demonstrated independently in accordance with the manufacturer's instructions, using a compensation roller. The easiest way is to remove the old belt and replace it with a new one. If it is not possible to purchase it, then you need to tighten it.

The motor block engine is fixed with four bolts.

Using a wrench, you will need to unscrew them a couple of turns, and pull the power unit in your direction, if necessary, the belt tension is loosened. A professional, by the degree of deflection, can determine how correctly this element is tensioned. If you press on it, it should sag 1 centimeter.

The second difficulty that the user often encounters is setting up the plow, which is attached to the back of the bed. For this they use not only a hitch, but also an adapter, and the second mount is considered one of the most reliable. First, the walk-behind tractor will need to be put on the lugs, and for this, bricks or firewood are placed under it in order to raise it from the ground. The height of the stand should be equal to the one that needs to be set to immerse the attachment. This indicator can vary from 16 to 20 cm.

It is the responsibility of the user to ensure that the vehicle is stationary. The required height is set along the holes that are on the vertical plow column. This is followed by the adjustment process, during which the field bar must adhere without gaps to the plow, and the stand must stand vertically in any plane.

If a standard hitch is used, the screw rotates when the nuts are loosened. In order for the amount of immersion in the soil of the equipment to correspond to the required value, it is important to observe the angle of rise. After the work is done, the user sets the blade angle, this is done from under the incisal edge. With appropriate experience, this can be done at the same time as adjusting the strut.

Owner reviews

There are many reviews on the Internet regarding whether a walk-behind tractor is needed on the farm or not. It is difficult to overestimate the advantage of such a technique, since it helps to significantly reduce the amount of manual labor. The walk-behind tractor, small in size and weight, can be easily transported in the trunk of a car, it helps to finish cleaning the territory or processing a small area faster.

When a user complains about a particular model, in practice it often turns out that all the problems are caused by non-compliance with the operating requirements, as a result, the equipment wears out faster.

For the features of choosing a walk-behind tractor and how to operate it, see the video.

The comment was sent successfully.