Features of the walk-behind tractor device and operating instructions

The motoblock is the most famous and demanded type of small agricultural machinery and is widely used to solve various agrotechnical tasks. The popularity of the unit is due to its versatility, ease of use and high performance.

Specifications

The main technical parameters of motoblocks are power, engine type, working width, plowing depth and fuel consumption.

- The engine power of modern models varies from 3.5 to 15 liters. with... Low-power samples with engines from four to six horsepower are used for seasonal work on small household plots ranging in size from 10 to 50 acres. In small country gardens with an area of 6 acres, walk-behind tractors are usually not used, and give way to motor-cultivators. Models with engine power 6-7 hp with. do an excellent job with fields from 40 acres to 1 hectare, and samples of the heavy class with motors of 8-15 liters. with. used on plantations from 1 to 4 hectares.

When processing larger areas, the use of walk-behind tractors is considered ineffective, and in such cases the help of a mini-tractor is required.

- The next important operating parameter is the motor type.... As mentioned above, gasoline models are installed on motoblocks with a capacity of up to 10 liters. with., and diesel - from 8 to 15 liters. with. At the same time, diesel units have a significantly greater motor resource and are used to perform heavy earthworks.

- An equally important technical indicator is the working width of the attachment, which directly affects the overall performance of the walk-behind tractor. So, models with a capacity of 2.57 kW are capable of capturing 60 cm of a surface, samples with a 2.94-3.6 kW motor - 80 cm, 3.68-4.41 kW units - up to 90 cm, and heavyweights with engines from 6.62 to 8.83 kW - capture 100 cm.

- Capture depth also depends on engine power and varies from 20 cm for low-powered models to 35 cm for serious models.

- Fuel consumption varies depending on the model and averages 0.9-1.5 kg / hour.

Device and principle of operation

A walk-behind tractor is a mobile wheeled device based on a single-axle chassis, comparable in functionality to a mini-tractor. The name of the walk-behind tractor was given to him in the mid-80s of the last century, while before that the technique was called a uniaxial pedestrian tractor. The old term was due to the peculiarity of controlling the unit, during which the operator is forced to follow him and hold the machine by the special handles.

During its existence, the unit has not undergone any major changes, becoming an intermediate link between a mini-tractor and a motor-cultivator, incorporating the best performance characteristics of both types.

The modern market presents a wide range of motoblocks from different manufacturers, however, their design does not have fundamental differences. All units are structured approximately the same and include the engine, chassis, transmission and control system.

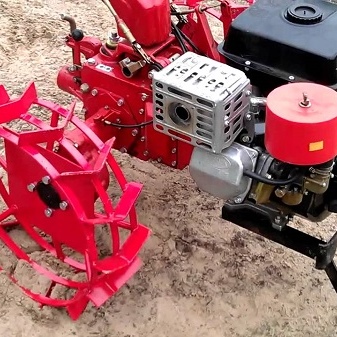

- Engine... Modern walk-behind tractors are equipped with internal combustion engines, and in lighter models they use gasoline four-stroke engines, while samples of the heavy class are equipped with powerful diesel engines. However, two-stroke engines can also be found on earlier models, but due to their age, such samples are quite rare. The motors, in turn, are equipped with air cooling systems, ignition, fuel filters, carburetor and lubrication system.

The starting mechanism in almost all models is represented by two types of starters - manual and electric. This allows you to start the engine in any temperature conditions, as well as after prolonged downtime of the unit.

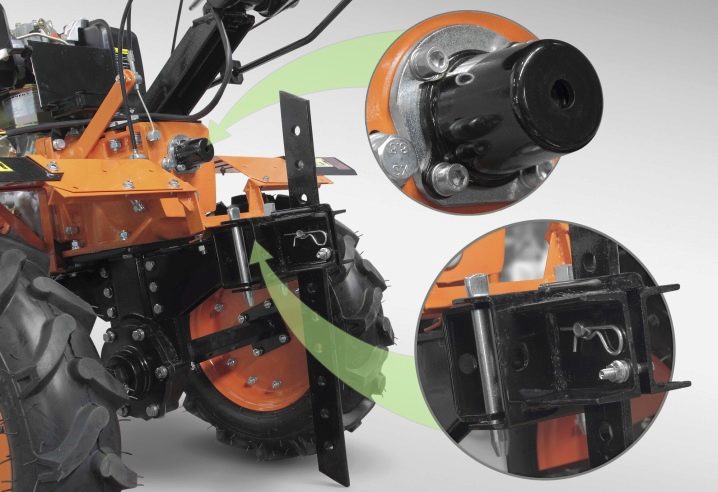

- Transmission, transmitting torque to the wheels, serves to change the speed of the unit, and consists of a gearbox, differential, clutch and gearbox. The latter, in turn, can have up to six forward and two reverse gears. Almost all machines are equipped with a power take-off shaft, with the help of which the torque is transmitted to the rotating elements of the attachment. The differential is installed mainly on heavy machines and provides rotation of the left and right wheels at different speeds. This is often necessary when processing difficult areas and plowing virgin lands.

Axle differentials are often equipped with a locking system, when activated, both wheels rotate at the same speed. This allows the walk-behind tractor to overcome high obstacles and transport goods off-road.

- Chassis motoblocks are represented by a strong steel frame on which the main units and wheel disks are attached. Most of the units are equipped with wide pneumatic wheels and are additionally equipped with lugs. The latter are metal rims with a deep aggressive tread. The lugs are designed to increase the weight of the walk-behind tractor, as well as to improve its grip on the ground during heavy excavation work, for example, plowing.

- Governing bodies are represented by a set of systems that allow you to change the direction of movement and speed of the walk-behind tractor, and include a steering wheel with a gear shift lever located on it, clutch and gas levers, as well as an emergency brake button. The control levers for the carburetor throttle and PTO are located on the corresponding units and are also easily accessible. The steering wheel itself in many models can be adjusted in height and stem depth, which allows you to adjust the walk-behind tractor to your height.

How to prepare for work?

Immediately after the purchase, the walk-behind tractor needs competent preparation, on the correct implementation of which the success of the further operation of the unit depends. Before starting the unit, you must carefully read the operating instructions. Usually, each stage of preparation for the launch and the launch itself are prescribed step by step there. However, if the unit was purchased hand-held and there is no accompanying documentation for it, then in order to do so, you should use a number of simple recommendations.

So, before the first start, it is necessary to stretch all the threaded connections of the unit, check the oil level in the tank and pour gasoline into the fuel tank. Despite the fact that most modern models of motoblocks run on A-92 gasoline, 95th gasoline is also successfully poured into them. The exception is two-stroke gasoline engines installed on old walk-behind tractors. They use gasoline diluted with engine oil in a ratio of 4: 1 as fuel.

With regard to diesel engines, in the summer period, you should fill in the summer diesel fuel, and in the winter - winter.

If this requirement is neglected and the engine is started at negative temperatures on summer diesel fuel, then after a short period of time the fuel will thicken and clog the fuel line. If the walk-behind tractor is no longer new, it will be useful to check the condition of the spark plugs and, if burnt-out copies are found, they should be replaced immediately. After the preparatory measures are completed, the walk-behind tractor is installed on a flat surface, the height and stem of the steering wheel are adjusted, and the smoothness of the throttle and clutch levers is checked.

How to get it right?

Starting a gasoline engine and a diesel engine is done differently, so there are a few rules you should be familiar with before starting.

- Gasoline walk-behind tractor start as follows: the choke lever is set to the "Choke" position, the gasoline tap is opened and pumped 3-5 times using a manual starter. Then turn on the ignition and pull the starter rope again. As soon as the engine is running, the choke lever is put into Run mode. If the walk-behind tractor is equipped with an electric starter, then to start it, you just need to turn on the ignition. The electric starter automatically starts pumping gasoline into the carburetor and does not require any additional actions from the operator.

- Diesel motors start-up is a little more difficult, due to the tendency of the system to airing, and diesel fuel to freezing. Therefore, when starting the diesel engine in winter time, the fuel of the appropriate density should be poured into the tank. There are two ways to remove air from the system. In the first case, you can work with the manual starter 5-7 times and pump the system in a similar way. If this does not help, then you should resort to the second, more time consuming, but effective method.

To do this, open the diesel fuel supply valve, then one by one unscrew all the fuel line connections. As soon as diesel fuel appears in the untwisted connection, it is twisted and moved on to the nozzle itself. Then they open all the fuel taps, set the gas to the middle position and, holding the decompressor with your fingers, squeeze it out and pump it a couple of times. After that, the decompressor is pulled back a little and gradually returned to its original position. Then they press it again and immediately pull the manual starter.

If done correctly, the engine should start.

User manual

In order for the walk-behind tractor to serve as long as possible, and to work with it was simple and comfortable, it is necessary to follow a number of recommendations.

- The running-in of a new walk-behind tractor is carried out within 25 hours, after which oil is added to the gearbox and the lubricant in the crankcase is completely changed. The next oil change is performed every 50 hours of operation.

- Every 100 hours of operation, the walk-behind tractor is cleaned of dirt and dust, the oil in the gearbox is changed and new belts are installed, and every 300 hours the throttle and clutch cables are lubricated.

- The installation of additional modules such as a plow, pump, cutter, potato digger or mower must be carried out with the engine off and on level ground.

- When the wheels slip on heavy soils and clay soils, it is necessary to attach additional weights to the unit, and when working with a plow on virgin soil - a counterweight.

- It is strictly forbidden to drive a walk-behind tractor to persons under 18 years of age.

- To extend the life of the walk-behind tractor battery, you need to store it at a temperature of at least 10 degrees. Otherwise, the density of the electrolyte decreases, while the wear of the plates, on the contrary, increases.

- Periodically check the air filter and the tension of the drive belt, and tighten the nuts, which are weakened by vibration.

- If an extraneous knock appears in the engine or if other malfunctions are found, it is prohibited to use the walk-behind tractor.

In the absence of certain technical knowledge and skills, it is not recommended to perform independent repair of complex components and assemblies.

For information on how to properly run a walk-behind tractor, see the next video.

The comment was sent successfully.