Swing metal gates: pros and cons

The gate is a key element of the fence of a country house or garage. Metal swing systems are quite popular: being a modern design, they have a lot of advantages, although they are not without disadvantages. What are the pros and cons of swing metal gates, this article will tell.

Peculiarities

Swing gates are a large wicket that provides access to the territory of the site for cars or trucks. Metal structures used in fencing are subject to the rule: the higher and more monumental the fence, the larger and heavier they are, because the weight directly depends on the amount of material used in them. Outwardly, it is one or two sashes fixed on pillars, which, depending on the model, can open in any direction (inward or outward), differ in an automatic or mechanical opening system.

In most cases, a small opening (small gate) is provided in the gate, which allows you to go inside without opening the gate itself. These systems are recognized as one of the simplest designs, they can be made in a single style with the fence of the territory of the house (garage) or differ from it, being a bright accent against the background of the fence.

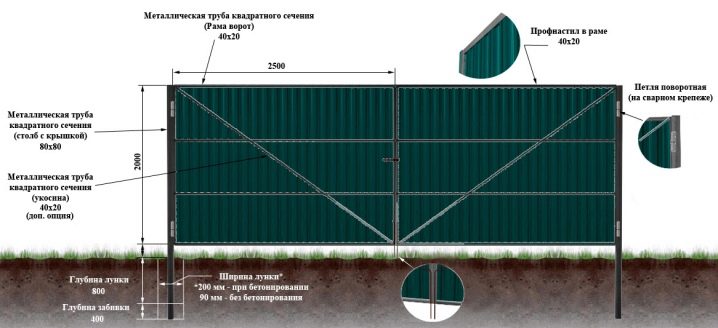

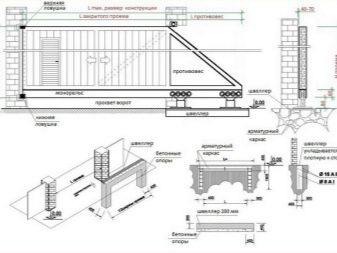

Swing gates require sufficient space for the leaves. They are equipped with beams with a load-bearing function, while it is important that the beams themselves are installed at the same distance from each other to balance the doors. Swinging metal gates (with or without a wicket) consist of several elements:

- the frame to which the finishing material and decor are attached;

- main metal cladding;

- loops required to fix the frame;

- pillars, without which it is impossible to install the gate;

- locking mechanism by means of which the gate opens and closes.

In addition to the basic set of structures, the installation cannot do without auxiliary raw materials (sand, cement, crushed stone, brick, paint), nails and appropriate equipment (grinder, square, level and welding). Do-it-yourself installation of swing metal gates is simple and is carried out according to a pre-prepared drawing, which, if desired, can be drawn up independently, taking into account your own preferences, or you can look at the finished version, adjusting it to specific measurements and budget possibilities.

During the manufacturing process, the profile is covered with a special coating that increases the material's resistance to adverse external factors. At the bottom of the profile beam, the models are equipped with special roller blocks that are activated when the gate is operating. Due to the use of the corner connector, the sashes, which are fastened by means of three-piece hinges, do not sag. The appearance is beautiful because all fasteners in it are carried out mainly in a hidden form.

Advantages and disadvantages

Metal swing gates are easy to install. They can be installed in an existing fence. Having a solid and quite presentable appearance, these systems have a number of advantages:

- they are often equipped with a wicket built into the door leaf or located in a separate section;

- can have different, including ergonomic shape, rarely make noise when the opening and closing mechanism is operating;

- can be equipped with a safe automated system of opening and closing, having a remote control panel;

- due to the material of manufacture, they are distinguished by a high level of safety and strength, having resistance to corrosion;

- are made from different raw materials with high performance characteristics and a degree of reliability;

- depending on the design, they decorate the fencing of the territory adjacent to the dwelling;

- with visible solidity, they are easy to install, their installation does not take much time;

- perfectly combined with various building materials (wood, brick);

- have different heights, which allows you to get rid of the annoying looks of people from the street and protects against thieves;

- based on the characteristics of the alloy used, they differ in cost, allowing each buyer to purchase an option taking into account taste preferences and the budget planned for the purchase.

These fencing elements, which are functional and comfortable, do not require special maintenance. Being both protection and decoration of the fence, they serve for a long time without needing to be repaired.

Due to the variety of modern styles and the availability of the necessary material in hardware stores, metal swing gates can be made to order according to an individual sketch.

At the same time, you can beat the design features by painting the surface, forged ornament, if necessary, insulate them or sheathe them with clapboard, which is especially important if these gates are part of the garage.

Minuses

With a number of advantages, metal swing gates have several disadvantages:

- a lot of space is required for their installation;

- during installation, beams must be deeply buried in the ground, which is not always possible;

- they cannot be installed without concreting the pillars, which takes a certain amount of time;

- with insufficient concreting, the pillars over time warp the entire structure;

- a certain space is required for opening and access, otherwise comfortable use of the gate is impossible;

- when equipping the structure with an electric drive, their cost increases.

In addition, metal swing gates are difficult to use in strong gusty winds: with a mechanical drive, it will be problematic to hold them.

Types of structures

Metal swing gates are different. In addition to solid structures, lattice varieties with different designs and manufacturing methods attract attention. Having a mechanical or automatic drive, they are divided into several varieties:

- frame with mesh - systems with different decorative elements from a tubular frame, characterized by lightness, reasonable cost and ease of manufacture (you can make it yourself with your own hands);

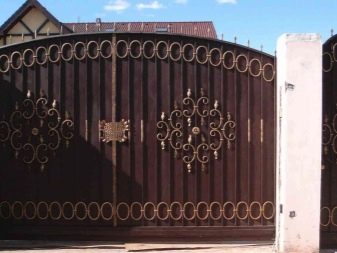

- varieties of corrugated board with forging elements - durable structures with a wide range of colors and designs, which are closed-type systems;

- forged mesh (lattice) - expensive gates made of forged rods, made with artistic forging, characterized by the strength of the frame itself;

- insulated - varieties, the use of which is associated with harsh climatic conditions (models for garages or other heated non-residential premises).

The choice of the desired variety depends on the budget and the characteristics of the fence itself. It is important to choose the gate in such a way that it matches the color or style of the fence.

Requirements

Swing gates are subject to certain requirements of GOST 31174-2003 with clearly defined requirements. At the same time, the subtleties of design and nuances of characteristics can be determined during design. Since the metal in large quantities has a corresponding weight, there are several requirements to be considered for flawless and correct operation:

- the movement of the shutters must be free: for this, the size of the gate is selected or calculated taking into account the dimensions of the existing transport;

- the minimum allowable distance from the rack to the side of the vehicle should be 30 - 35 cm;

- the gate must be resistant to burglary: the thickness of the galvanized sheet must be at least 2 mm;

- to provide protection from rain and snow, it is necessary to use vertical locks in the structure, securing the canvas and preventing skewing;

- the gate opening and closing mechanism and the corresponding units must be manufactured in strict accordance with the design documentation and the manufacturer's calculations;

- visible defects of the metal surface are excluded;

- when treating the surface with a paint and varnish composition, its thickness should be at least 30 microns;

- the minimum height of products used for the private sector should be about 3 m (for industrial enterprises this figure is 5 m);

- the strength and continuity of the welds must comply with GOST;

- components, frame and frame are selected with a double margin of safety, having a confirmation of the quality mark in the form of a corresponding certificate of the State Sanitary and Epidemiological Supervision Regulations.

Materials (edit)

Swing gates are made from various raw materials, including metal profiles. To make them practical, reliable and durable, they are responsible for the choice of material. Firstly, reliability and strength depend on this, and secondly, the weight and peculiarity of the installation technology. For cladding, they try to use durable raw materials. Choosing wood as a basis, you need to take care of additional protection against decay and antimicrobial treatment... This will extend the life of the material.

If you plan to use corrugated board, you should give preference to classes C, H or HC.

The raw materials for the frame are different, but subject to the characteristics of the drive. The welded type is durable and reliable, but due to its high weight, it is completely unsuitable for doors with automatic controls. In this case, the best solution would be aluminum, which is lightweight. The bolted frame is quite simple to manufacture, however, of all types of material, it has a shorter service life.

The best material for pillars is brick. It is distinguished by its strength, durability, capable of withstanding the large weight of the metal frame and the entire structure as a whole. Concrete is a worthy competitor to it: this material, in addition to high reliability indicators, allows for cosmetic repairs and surface treatment, so that the pillars can be decorated taking into account the stylistic idea chosen for the design.

Professional advice

In order for metal swing gates to serve for a long time and do not need repair, it is worth taking note a few professional recommendations:

- it is advisable to use metal for the frame: it is more durable than wood, more resistant to negative natural factors and mechanical damage;

- if the design provides for the surface painting, first you need to process the metal with sandpaper in order to exclude the appearance of rust, cleaning and welding smudges;

- if you need to degrease the surface, you should use any solvent;

- if it is necessary to insulate the gate, this must be done on the inner surfaces of the doors, using expanded polystyrene or mineral wool, excluding the formation of air pockets;

- sheathed the sashes preferably with steel sheet, the thickness of which is more than 2 mm;

- the best lock for metal swing gates is a hinged one, while a powerful and reliable bolt can be installed, which must be protected from moisture and severe frosts (the best type of key is a tubular key);

- when calculating the width of the gate, it is worth starting from the available space (usually a three-meter width is enough for light vehicles);

- it is not recommended to make large gates where they are not needed: this leads to high wind loads and will require additional reinforcement to avoid skewing and subsidence.

Successful examples and options

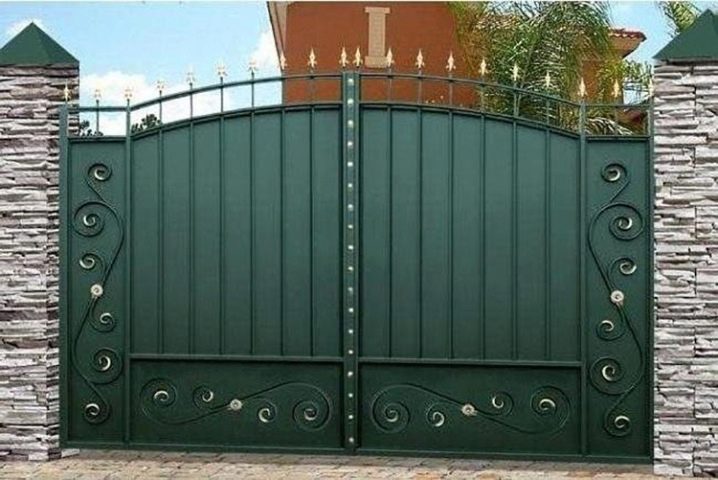

Large gates made of metal profiles are perfectly combined with forging elements, creating a clear geometric mesh pattern: standing out against the background of a high fence, they are the accent of a brick fence.

The construction of sheet material with forged rods and gilding successfully crowns the fencing of the private sector with semi-antique columns: complemented by a wicket and peaks, the fence looks like a single ensemble.

The laconic gates, complementing the brick pillars, harmoniously combine with the overall style through a single shade, while looking beautiful with the stone finish of the fence.

Curly forging, spikes, ornament and sheet material are an excellent solution for a fence against a white brick background: stylish and modern.

For information on how to make a metal swing gate yourself, see the next video.

The comment was sent successfully.