Corrugated gates with forging elements: beautiful design ideas

Decking is one of the new building materials, but it has already proven itself well. It is widely used both in industry and for the needs of the population: it is used in the manufacture of fences, in covering the roof and finishing the outer part of buildings. Residents of the private sector appreciated the beauty of corrugated gates and increasingly began to decorate their fence with elegant wrought iron products. They are attracted by their affordable price and the ability to make a product with their own hands.

What it is?

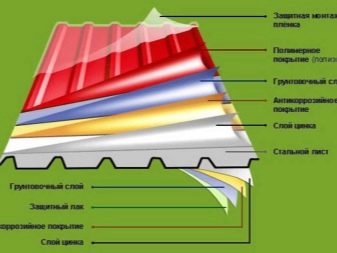

Decking is a corrugated metal sheet. It is made from different metals. Steel is used in production, polyester, zinc and aluminum, as well as their alloys, are used for the needs of the private sector. On forming machines, flat sheets are given a corrugated shape. The profiled sheet is covered with several layers of coating: galvanized, primer, anti-corrosion layer, painting.

The corrugation is wavy and trapezoidal, the strength of the material depends on this. The quality of the profile also depends on its height: the higher the sheet, the stronger it is.

Several grades of profiled sheet are produced for various applications:

- C is a low canvas, suitable for the manufacture of gates and fences.

- NS - higher and stronger than the previous one, used for wall cladding.

- H - a profile of increased strength, it is used for sheds and ceilings.

Advantages and disadvantages

For the manufacture of gates, many people use corrugated board, because it is a modern material, and in combination with forging elements, you can create perfect fencing designs. Plus, it has more pluses than minuses.

Advantages:

- Nice appearance.

- Ease.

- Durability.

- Resistance to a certain level of mechanical stress, fire resistance.

- It does not require special care.

- Amenable to self-assembly.

- Has an anti-corrosion coating, resistant to moisture and other environmental influences.

- Large selection of colors, brands and designs.

- Affordable price.

Disadvantages:

- The profile is capable of deforming with a strong impact, it can be cut with an ax.

- If the anti-corrosion layer is violated, the canvas will begin to deteriorate under the influence of moisture.

- Peeling paint, dents and scratches can ruin the finish.

- Decking can be very hot from the sun.

- The material is quite noisy on impact.

Types of fences

By the way of opening, the gates are divided into several types:

- Swinging - a favorite option among the population. The swing of the door takes up quite a lot of space. You can install the gate yourself. For this, metal supports are placed at a depth of about a meter and fixed with concrete. The frame on which the profile will be held is created from metal pipes. The gates are hung on poles with hinges.

- Recoil - such doors roll back along special rails that are installed at the top or bottom of the structure. They are opened mechanically or automatically. The gate is good when there is a shortage of territory. Both options go well with forging elements.

- Lifting gates - with little effort, they rise up. Their beautiful appearance and fragility against breaking make them very popular. Such gates cannot be decorated with forging, but a wicket and a fence can compensate for this gap.

As for the gates made of profiled sheet, equipped with forged products, they are divided into:

- Decorative - use forging in the form of decoration, it does not in any way affect the strength of the structure itself.

- Massive - stamped by manufacturers according to the created sample (exclusive will be expensive). The forged frame allows the profiled sheet to gain special strength and protect the gate from strong mechanical stress.

Having dealt with the types of gates, you have to make a choice in favor of any design. The gate should be in harmony with the surrounding area and the house. It would be right for the style of the product to match the design of the yard and the house.

Materials to create

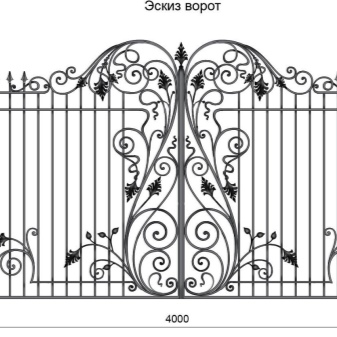

At the initial stage of work, sketches are made with the exact dimensions of the future gates. According to them, taking into account the size of the profiled sheet, the required amount of material is calculated. For further work, you will need material for support. The height of the post depends on the design of the gate. 1 additional meter of height must be dug into the ground for reliability. For work, you will need corrugated board, a pipe for the frame, tools for metal processing. As well as forging elements, the installation of which will be carried out by welding or screwing.

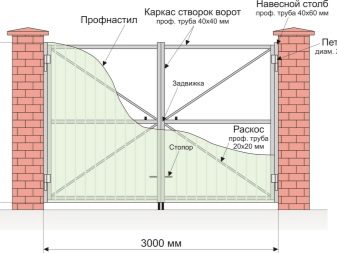

Swinging

You should start working on creating a gate with the installation of supports. Having marked out the place, they dig holes under the pillars more than a meter deep. The material for the support is cut to the required length (sash size plus 10 cm for the gap between the ground and the product plus depth). The installed pillars are reinforced with cement mortar.

When starting to create a frame, it should be borne in mind that its size will affect the weight, respectively, and the choice of material strength.

At the initial stage, it is necessary to organize a flat platform for working on the structure. The gate frame can be bought ready-made, but if you decide to make it yourself, you need to stock up on a welding machine, grinder, screwdriver, metal scissors, nylon thread. For metal processing, you will need a primer, anti-corrosion liquid and paint. You will also need a locking mechanism.

For self-assembly of the frame, a profile pipe with a section of 40 by 20 mm is required. A rectangular structure is made from it with the help of a welding machine, reinforced with metal corners. The long sides of the frame are connected by several jumpers. The finished frame is tried on to the supports and the place for the hinges is marked, then they are welded on.

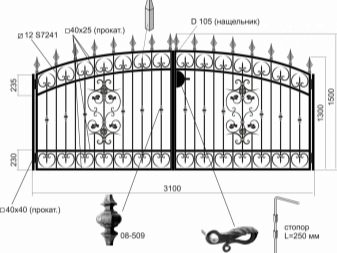

At the next stage of the work, the corrugated board is decorated with forged elements. They are laid out on the canvas according to the sketch and fixed by welding. First, they work with large forged elements, then with small ones.

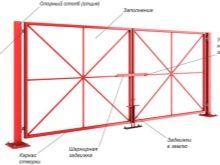

Recoil

Sliding gates are automatic and mechanical. To install the product with your own hands, you can consider the second option. The advantages of these gates are their compactness. Moving along special rails, they do not take up space with the open doors.

Metal corners are involved in the manufacture of the frame, they are welded together in a checkerboard pattern at a distance of about 40 centimeters. Install the upper channel. Then the profiled sheets are mounted with roofing screws. The cut-to-size canvas is overlapped onto a metal frame. A stiffening rod, a locking mechanism, a latch and stops are installed on the finished gate. The gate is complete. As in the case of swing gates, the structure can be decorated with forged elements.

Having started work on the foundation, they prepare a structure with a roller block and embedded elements. Two holes are dug below the freezing depth, a structure with a block of rollers is installed in them for moving the canvas, and the holes are poured with concrete. The foundation is carried out to the middle of the gate.

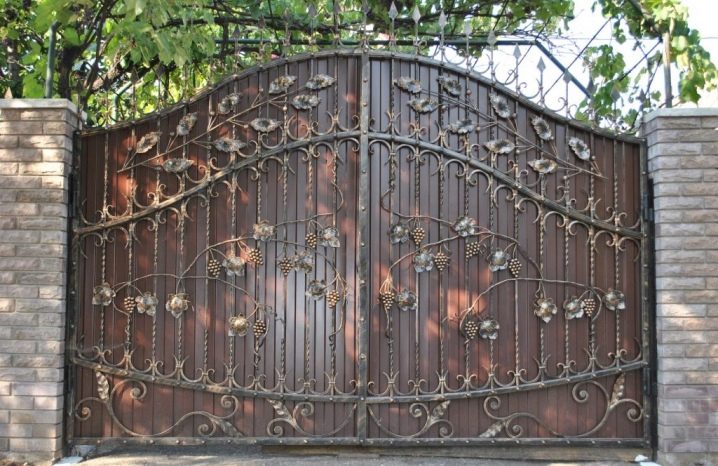

Design ideas

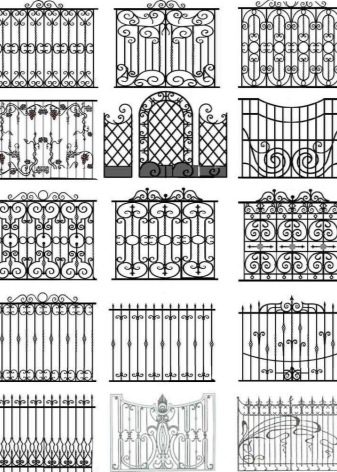

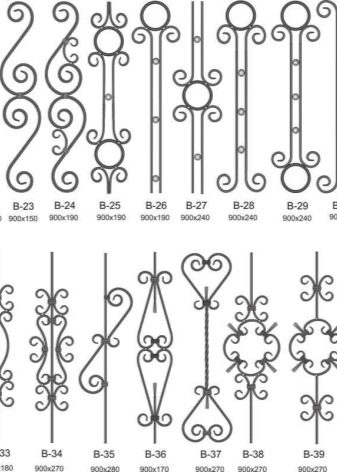

Forging elements are amazingly beautiful metal products. There are works of authorship that are real works of art. The stamped elements that fill the construction market also do an excellent job of their purpose. The gates decorated with them look representative and aesthetically pleasing.There is a wide variety of forged items on sale - peaks, curls, baskets, openwork spirals, balls, spheres, a decorative flower row of products in the form of leaves, buds, vines and vines.

When you design the gate yourself, you do not need to have a special talent for drawing, stencils and templates can always help out. Having drawn up a sketch, you can stock up on the necessary details of the future forged product, and then assemble it as a designer, securing it by screwing or welding. Stamped elements, adapted for quick assembly, give the door an elegant look and increase its rigidity.

There are a wide variety of styles for gate design ideas, you just need to choose one of them.

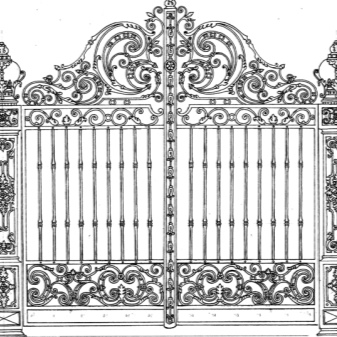

Many people prefer to decorate the gate design with forging elements in a classic style.

Airy, but austere decorations on the theme of floristry are painted in bronze or gold. The ornament of climbing plants is proportionally repeated.

Gothic style is more suitable for massive gates. The decor is simple with a strict pattern. The use of thorns or black color in the decor will not be to everyone's taste, but lovers of solid reliable gates will be able to appreciate this style.

Those who do not like pretentiousness and a floral theme can use the high-tech style: straight lines with a clear calculation, no ornaments and decorations. Chromium elements and different types of metal are used.

The complete opposite of hi-tech is the baroque style. It has an active riot of flora, fauna and many other elements. The gate appears to be on display for general delight.

Modern is beautiful, but does not like symmetry and clear geometry. All its lines are smooth, floating freely. Lack of logic can be very attractive.

You can choose any style of fence design with forging elements. The gates made of corrugated board not only delight in appearance, but are also able to serve their owners for up to 50 years.

How to make a gate with your own hands, see the next video.

The comment was sent successfully.