Swing chaise lounges: features and manufacturing technology

The dacha is more than just a place where vegetables and fruits are grown and prepared from them. Even those who use their land for purely utilitarian purposes need a good rest, all the more important for those who are striving specifically for leisure in the suburban area. Chaise lounges are of considerable value in this regard, which make life much more comfortable.

Peculiarities

Garden swing has long been transformed from a luxury item into a necessary attribute for a summer residence, harmoniously included in any landscape design. This device can be adapted for both children and adults. You can put them:

- in gardens;

- in gazebos without a roof;

- on terraces;

- next to any tree.

But choosing the best option can be quite difficult. It is useful to give preference to swing-chaise lounges, which are easy to use and very easy to unfold. There are structures with a canopy, effectively replacing the roof and perfectly holding back precipitation. By using high-quality springs, it is possible to guarantee that the swing-deck chairs will withstand a load of over 200 kg.

Thinking over the design of the product, you need to pay attention to such points as:

- protective paint;

- main frame material;

- fastening method;

- the number of people who can take advantage of such an attraction.

A standard outdoor chaise longue swing allows a couple of adults and a child to sit comfortably. Moreover, when the structure sways, it should create only positive emotions; it is very important to achieve lightness and weightlessness.

Most of these products can be placed in a room in a house or apartment. The main material of construction is steel. This preference is due to the need to withstand significant loads.

How to make it yourself?

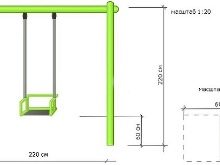

The simplest type of swing using a U-shaped frame can be obtained without the use of welding. You just need to dig the pillars into the ground. As pillars, profile pipes are used, the cross-section of which is at least 6x6 cm.In addition to being buried in the ground, they will have to be concreted. The total height of the structure is between 2-2.5 m above the ground and approximately 1 m (at least) below the surface.

As a horizontal bar, rectangular pipes with a minimum size of 6x4 cm are most often used. The length of the structure varies from 150 to 200 cm, this indicator is selected depending on the width of the seat. To keep the crossbar firmly in place, it is fixed with M16 bolts with locknuts. The seat is recommended to be made from a pair of metal corners. Their length is 400 mm if there is no backrest, and 800 mm if such a part is provided. The supports must be inserted into deep narrow grooves that cannot be made with a shovel. A garden drill comes to the rescue, which should form an extended bottom.

This technique will allow in the future to exclude the pushing of concrete upward by the forces of frost heaving. After sprinkling the bottom with gravel and installing the pillars along a plumb line, they are sprinkled with the same gravel. The filled-in material is compacted manually.

After that, it is watered with a slurry of cement (concrete of category M100 is preferable). The supports are introduced at a time when the concrete is already relatively strong, but has not yet fully hardened. Next, having marked the holes in the crossbar, they are drilled using a drill with a diameter of 1.6 cm.Now you need to tighten the crossbar with bolts using grovers and locknuts.Attention: each position for the eyebolt needs to be reinforced.

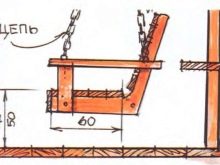

Next, you can take up the preparation of the seat. The corner is bent as needed without welding. A triangular cutout is made on one face. Since most often the back and seat should form an angle of 120 degrees, one of the vertices of the triangle is made 60 degrees. You can tighten a beam or plywood with a thickness of 1.5-1.8 cm to the corner using bolts with half-countersunk heads.

The chains are selected so long that the seat with the backrest reclines 10-15 degrees back. During work, mainly stainless steel carabiners are used. If carbines are taken from ferrous metal, then they must have an outer zinc layer. The working part of the mount can be made as a latch with a spring or a threaded sleeve.

Regardless of the nuances of a particular product, the swing must be painted to protect it from the vagaries of the weather.

By preparing a working drawing, you can show your originality, show a variety of design solutions. But there must be necessarily reflected:

- support frame;

- crossbar line;

- side parts;

- seat anchorage points.

The recommended scale for the drawing is 1: 20 (as in example 1). You can make a swing-deck chair for children with your own hands and from wood. How they will look is shown in example 2. Equipping with soft seats is only welcome - this will significantly increase the attraction of the attraction.

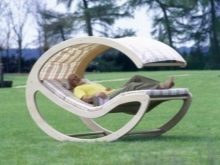

In the next video, you will find a master class on making the third version of a swing-deck chair for a summer residence.

The comment was sent successfully.