All about hydraulic drills

For drilling, in any case, specialized equipment is needed, and this is exactly what the hydraulic drill belongs to. It can handle a variety of specific tasks. The scope of use of hydrodrills is quite wide, ranging from drilling conventional wells, and ending with the creation of recesses for telephone poles or road poles.

Peculiarities

The hydraulic drill can not only be used in a number of areas of construction work, but also has several key features:

- drilling can be carried out in different types of soil and near residential buildings;

- the hydraulic drill can last much longer than the specified standard service life;

- noise during operation does not exceed the permissible limits;

- the torque of the drill in professional equipment has high performance;

- the borehole can be quite deep and wide.

The torque is provided by hydraulics that rotate the drill. It is as a result of this that it can penetrate into the soil even into the hardest layers of the soil. Today there are quite a lot of models, their technical characteristics differ as well as the equipment. Based on this, you need to weigh which hydraulic drill to choose for yourself.

Advantages and disadvantages

The advantages and disadvantages of using a hydrodrill largely depend on a number of conditions. It is necessary to take into account the expected geological conditions of work, the type of soil and the complexity of the task at hand. Based on this, a suitable type of hydraulic drill is selected. And only then can we talk about the hypothetical advantages of this or that method. For example, if in the end the hammer drilling method was chosen, then the advantages are as follows:

- suitable for solid rocky soils;

- the walls of the well are easily cleaned, and the water layer itself remains intact;

- the drill goes deep, so that you can take samples and study the characteristics on different layers of the soil;

- after drilling operations, there is no need to wait a certain amount of time for the final well installation.

Despite the number of advantages, this method also has its disadvantages. It is not suitable for sandy soil, drilling is carried out strictly vertically, and the rotation speed is quite low compared to other models.

Before making a final choice in favor of a particular method of work, relying on their advantages and disadvantages, it is worth first considering all types of installations and the general specifics of their use.

Views

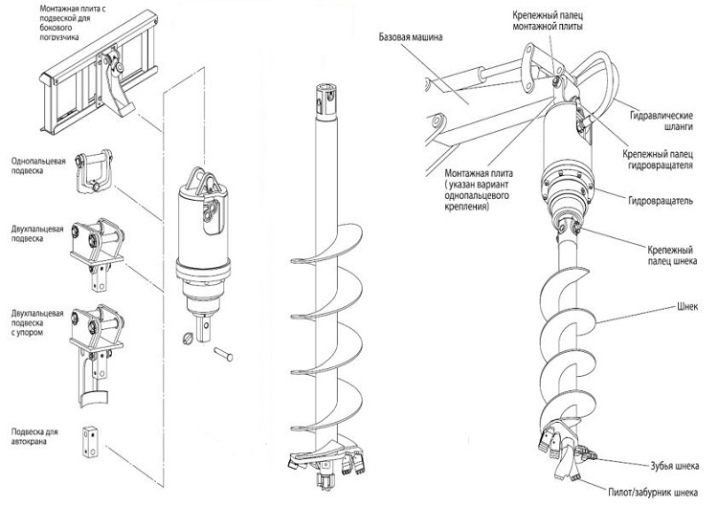

The hydraulic drill can be matched to an excavator or manipulator, and even to a mini loader. It is considered a piece of equipment for specialized, professional equipment. The basis for any design is usually a wired mechanism and auger, so the attachment usually looks like a hinged mechanism. It can be used to perform a variety of different tasks:

- create different depressions in the soil in diameter;

- prepare everything you need to organize underground communications from scratch;

- create holes of the required depth for a water well;

- take soil samples for further analysis;

- prepare everything necessary for the installation of fences and electric poles;

- use yamobur for landscaping the territory.

And this is just a small list of tasks for a rig. Otherwise, it all depends on the goals and the characteristics of the specific equipment.They will differ depending on the type of construction. Based on these features, hydraulic drills can be divided into several types.

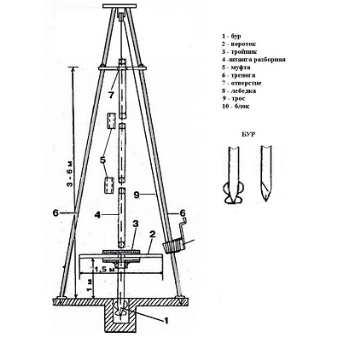

Shock rope

This method is far from new for a hydraulic rotator, and the design itself can be called almost classical. Depending on the type of soil, different tools are used in the structure. This is usually a chisel with a bailer. If the first provides exactly the impact force, then the thief, on the contrary, allows you to remove fluid from the well. This is important for some types of soil. The design must have a casing and valves.

Such equipment can be made by hand, pumping out of liquid is provided from polypropylene pipes, and with the help of fasteners, the whole structure is connected to the shock part. This is the easiest option for making your own hands.

Auger

This method has only one rather serious drawback, which reduces the scope of its application: limitation on the depth of well drilling. Therefore, this method may not be suitable for a tractor or when working on large areas. With auger drilling, the depth of the wells will be no more than 20 meters. This method is suitable for:

- installation of fences;

- extraction of soil samples at different depths;

- installation and dismantling of piles;

- creating holes for landscaping the site.

The type of soil at work also requires attention when choosing equipment. Since, if the rock is too hard, then drilling will become less effective.

Rotary

Rotary drilling is more suitable for hard rock formations than auger drilling. The main tool is a chisel, which is amplified by hydraulic pressure, and due to the diameter of the tool itself, several necessary tasks are solved at once.

- Reduces energy costs. Due to the design features, they are minimized here;

- Maintain the integrity of the well and string during operation;

- They work at great depths.

It is thanks to this that water-bearing wells and workings are easily created for a number of sites in a short time. Water also helps to clear the bottom of various types of debris during processing, so that the equipment is almost universal.

Manual

Hand drilling is more suitable for shallow depths and private suburban areas. For this, in addition to the equipment itself, water is needed, which will perform several tasks:

- destroyed areas and debris are immediately washed out;

- the tool is cooled with the help of a liquid;

- the body of water grinds the edges of the well.

You can make a device for manual drilling with your own hands. If the wells are small, it will fully justify the time spent and will be much cheaper than professional equipment.

How to choose?

Any professional equipment for well drilling usually includes:

- adapter;

- hydraulic rotator;

- hoses;

- drill auger;

- extension for adjusting the depth of work.

It is worth choosing a suitable device based on the tasks set. Expensive professional equipment for working with hard rocks is suitable in the appropriate area, but not in the country. The device must be strong and the shaft must withstand the required loads. In addition, the shaft can be of different shapes, which is suitable for different types of wells and drilling. It is worth considering and exploring everything the market has to offer before making the final purchase or DIY.

How to do it yourself?

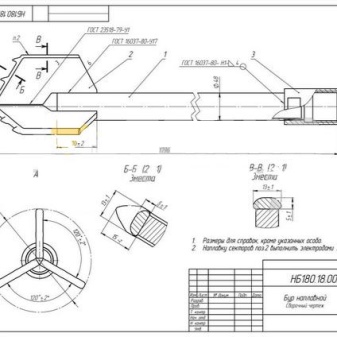

A homemade hydraulic rotator will serve no worse than any factory analogue, provided that all the rules and points of the instructions have been followed. When choosing a suitable model, it is worth remembering that it is easiest to make the simplest at the very beginning. Having chosen a suitable device, you can proceed to study the drawing.

Drawing

It should show the entire structure with dimensions, fasteners and the indicated GOST marking.In such conditions, it will be easy for anyone to read the drawing, even a beginner who has never been involved in self-assembly of such equipment before.

Manufacturing

Making a hydrodrill with your own hands takes place in several stages. First you need to get:

- up to four corners of a given thickness and length, the parameters must be observed exactly, up to the wall thickness;

- casing pipe of the required diameter according to the drawing;

- adapter, fasteners and other small parts to combine the structure with each other;

- two-finger auger or adapter.

The list of what is necessary may change, and the instructions for self-production itself may expand and become more complicated. It all depends on the key design features of a specific model for self-reproduction.

For the first time, the following instruction will work:

- cut the tapered part of the drill from wood;

- set the markings required in width for the future pipe;

- cut out the inner and outer holes for the corners;

- weld the pipe (in parts) to the structure, cutting off the sharp edges of the corners;

- the drill is put on the pipe, and the structure is finally welded.

It is preliminarily recommended to practice cutting and cutting key structural parts, this will avoid serious mistakes and do everything right the first time.

How to use?

After the type of soil has been assessed and a suitable drilling method has been selected, work can begin:

- rinsing solution is supplied through the hose;

- after that, the drill begins to move and purposefully destroys the rock;

- waste from the ground is washed out with water and fed into a special bag;

- the process is repeated until a well of the required depth is created.

Strictly speaking, drilling does not require too much physical effort from a person. Much more important in this case is strict adherence to technology and the correct selection of equipment for the type of soil on the site. For the rest, it remains only to follow the instructions, and anyone, regardless of past experience, can handle this.

The comment was sent successfully.