All about Stihl motor-drills

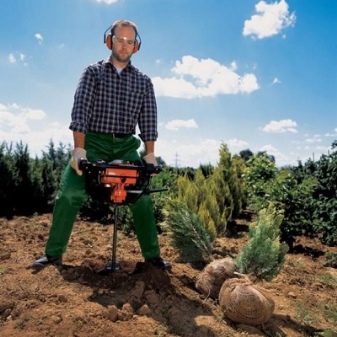

Nowadays, thanks to modern technology, many manual work can be replaced with a power tool. One of these devices is a motor-drill. In this article, we will look at motor-drills from Stihl.

Peculiarities

The founder of Stihl is Andreas Stihl, who opened his design office 90 years ago. At that time, he had a logging industry, which was based on manual logging. It was this hard work that provoked the owner to quickly make an electric chainsaw. So over the years, the time has come for the production of a motor-drill.

A motor-drill is indispensable in everyday life and construction, because with its help they build supports for various fences, dig depressions in the ground, its use greatly facilitates the installation of supports, poles and much more. Stihl manufactures a variety of gasoline powered mobile augers. They differ in their power, fuel tank volume, revolutions, size and cost.

Each model has passed the test, therefore it has a guarantee for long-term operation.

The lineup

The range of Stihl motor-drills is quite large. Here's a look at the most popular models.

Stihl BT 131

The Stihl BT 131 model is designed for drilling holes with a diameter of no more than 300 mm. The device has a powerful 36 cc engine with a durable air filter. The frame is equipped with anti-vibration elements and a stop button is provided on the control handle for safe and comfortable operation. All controls are integrated into the right handle, so while drilling the hand will remain in the working position, and control is carried out with a simple finger press.

Rubber coated handles prevent slipping. The cushioning pads fit snugly around the foot, allowing precise indentations to be made without the fear of vibration shocks. The power of this model is 1.4 kW, and the weight is 10 kg. The volume of the fuel tank is 0.7 liters. The spindle speed is 20 min-1 and the sound power level is 100 dB (A).

Stihl BT 45

The Stihl BT 45 gas drill has the following technical characteristics:

- weight is 4.8 kg;

- engine power 1.1 l. with.;

- the frequency of rotation of the auger is 2710 rpm.

The use of the device is intended for drilling depressions in soils of the first and second categories, as well as in ice surfaces. It is used for drilling wood. The model is equipped with a two-speed reverse gearbox, thanks to which the device can be easily removed if it is jammed. There are two speeds forward and one reverse. The motor-drill is equipped with anti-vibration elements, due to which the level of vibration and the load on the muscles is reduced.

Comfortable work is provided by rubber non-slip handles.

Stihl BT 360

The professional Stihl BT 360 is designed for two operators. The main area of use is drilling wells with a diameter of up to 350 mm. It is also used for drilling in heavy soils during long-term operation. The engine power is 3.9 liters. with. with a working volume of 60.3 cm3. The weight of this model is 28.5 kg. Although the model is powerful and efficient, it is very compact thanks to the foldable base frame.

In case of blockage, counterclockwise reverse rotation is provided for easy removal of the tool from the soil.The special ElastoStart starter significantly reduces vibrations and stress on muscles and joints. Thanks to the damping element in the starter handle, the vehicle starts up smoothly, without jerks. The volume of the tank is 0.55 liters.

Stihl BM 121

The Stihl BM 121 motorized soil drill is designed to perform a wide variety of work: both for drilling conventional wells and for taking samples from the soil. The device is capable of drilling a recess up to 200 mm in diameter. It weighs 9.4 kg and has an inner cylinder diameter of 20 mm. The engine power is 1.3 kW, and the fuel tank volume is 0.64 liters. In the event of a jammed drill, a lock is activated, thanks to which the device can be easily removed from the ground by turning it counterclockwise.

The model has a multi-function handle with a locking lever. Thanks to him, control is easy with both the right and left hand. The frame handle is equipped with anti-friction elements for comfortable and fatigue-free work. Widely shock-absorbing pad fits snugly around the foot while drilling, ensuring precision tool operation. The ElastoStart significantly reduces vibration forces and starts smoothly.

How to choose?

When choosing a motor-drill for earthwork, first of all, you need to rely on the complexity of the task and the density of the soil. All models differ in their weight. Based on this, the lungs are designed for working with sandy soil or black soil. With these devices, holes of about 2 m can be drilled with one operator.

Heavy-weight models are considered professional and are therefore used for particularly difficult, compacted soils. Two people work with such devices. If you are purchasing a device for homework or garden planting, then you can opt for models with low power, which are easy to operate on your own.

For rocky ground, it is better to purchase a semi-professional model. The professional ones are equipped with a hydraulic drive that increases power. To work with such variants of equipment, two people are required. Keep in mind that the motor-drill has its own fuel tank volume, therefore, for long-term work, you must choose a model with a large volume.

The drilling depth of the auger, which comes with the motor-drill, directly depends on its length. If the auger is short, then the hole depth will be small, and to increase it, it will be necessary to additionally purchase a shaft extension. Therefore, for drilling wells, it is better to choose a model with a long auger. The material of manufacture plays an important role, since the service life of the device depends on it. Usually the screw is made of stainless steel, which is resistant to temperature extremes and corrosion.

User manual

In order for the equipment to serve you as long as possible and perform its functions efficiently, you must carefully read the operating instructions. If this is your first time using the tool, then do not try to load it to the maximum. The first few operations should be designed for an average load, since all movable parts must rub against each other. The engine will reach its maximum power only after 5-10 fuel fillings.

During work, it is necessary to strictly adhere to the safety rules, strangers should not be in the working area. The device must be used strictly for its intended purpose, if it is provided for a diameter of 200 mm, then there is no need to try to enlarge it.

During operation, the equipment must be stable, and the handles must be dry and clean. In case of imminent danger, you must immediately stop the engine.

Pay attention to how the engine idles. After releasing the control lever, it should not rotate. During drilling, the operator must use protective hearing capsules to limit the perception of loud sounds.During long-term operation, observe short breaks to prevent engine cooling and worker fatigue. After finishing work, inspect the device for leaks from the fuel tank. It must be stored in a dry place, away from sources of ignition.

If you have not used the tool for more than three months, then the fuel tank must be emptied and well ventilated for commissioning. And it is also necessary to free the carburetor to prevent the membranes from sticking together. The air filter and cylinder fins must be thoroughly cleaned. Only after these manipulations can the equipment be refueled and used for work.

The comment was sent successfully.