Selection and installation of the engine on the "Mole" motor-cultivator

Small-scale mechanization means are used in subsidiary farms, including the "Krot" motor-cultivator. The unit is successfully controlled with surface treatment and loosening of the soil, weeding the space between the ridges, potato headers and transportation of goods. It is characterized by simplicity and durability in work, agility and small size, which is practical for transportation in a car trunk. However, some farmers strive to improve the unit in every possible way, for example, put another electric motor.

Unit device

There are almost no useless elements in the structure of this Russian product, however, the design of the cultivator is implemented in such a way that the owner can use it in a variety of tasks. Due to the strength of the key components, the unit is able to withstand long-term loads. The unit structure includes the following components:

- the frame, which is assembled from 2 semi-frames, is fixed to the gearbox housing by means of bolts;

- tubular handle and holder for using attachments;

- control knobs;

- pneumatic wheels, which are fixed on the output shaft of the gearbox;

- 2-stroke single-cylinder engine with a forced air cooling system, fixed on the chassis - mates with the gearbox shaft through a V-belt transmission.

Of all the components, the motor deserves special attention - its volume is approximately 60 cm3, the torque is 6 thousand rpm. / min, and the power is 2.6 horsepower. The engine operates on a mixture of gasoline and engine oil. It is easy to understand that the small power of a typical engine pushes owners to rotate it. It is quite easy to carry out this procedure, you just need to correctly select the internal combustion engine for the "Mole" motor vehicles.

Choosing an engine

Engines with a capacity of 4 to 6.5 horsepower can be installed on the Mole cultivators, as a result of which, to carry out any tasks, it is necessary to select a unit based on efficiency. If necessary, you can install a new motor with your own hands, but all actions must be carried out taking into account certain points, on which the service life and the efficiency of using the equipment depend. Let's consider some of the most popular internal combustion engines in more detail.

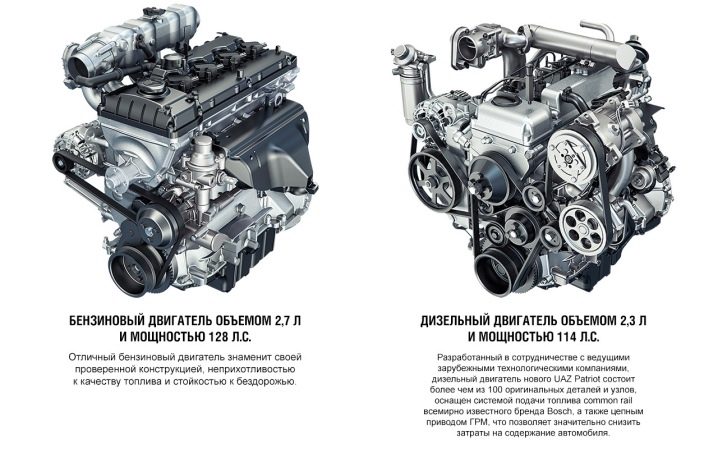

Honda GX270

This is a durable motor (made in Japan), its power is equal to 4 horsepower. The 4-stroke gasoline internal combustion engine has a very decent operating time, it functions smoothly and quietly, in addition, it stands out for its restraint in fuel consumption. Other than that, it has a decent balance.

The overhead valves in the gas distribution system maintain a self-sufficient level of efficiency, ease of use and superior performance even at low rpms.

Lifan 168F-2

The Chinese gasoline four-stroke engine Lifan 168F-2 is in demand among users of small agricultural machinery. These engines have long and successfully operated on a variety of devices - walk-behind tractors, vibrating plates, motorized pumps, gas generators, motor-cultivators, and so on. 4-stroke ICE Lifan has high functional characteristics.It is an absolute copy of the popular modification of the Honda GX200. It is extremely economical in terms of fuel consumption, is equipped with a cast iron cylinder liner, and starts without much effort in a variety of weather conditions. The motor is equipped with an automatic speed setting.

Sadko DE-220

Sadko is a very suitable option for installation on the "Mole". The cost of this power unit is relatively low. "Sadko" is powered by electric energy. Its power is 4.2 horsepower, and it is connected to the mains through the cable that is included in the kit.

Patriot

This is a fairly reliable power unit, requiring an uninterruptible power supply near the site to work. Any of these engines fits perfectly into the design of a motor cultivator, and mounting will require a minimum amount of chassis alterations.

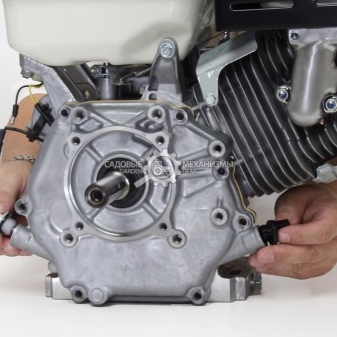

Replacing the engine

Installation of a new motor does not cause anything complicated and is completely similar for all brands and modifications with similar parameters. It is enough to remove the old motor and install a new one. Tension the drive belt and fix the motor with 4 M8x40 bolts on the unit chassis. Similarly, it will be necessary to change the friction wheel - in the trade there are 2 and 3-ribbed wheels for Lifan motors and similar modifications of other manufacturers. The drive belt is the old size 750A.

Additional improvements:

- on the frames of units manufactured before the 2000s, you will need to drill 2 holes for the motor fasteners, on new equipment there are already such holes;

- you will probably need to adjust the safety barriers of the drive belt - operating the cultivator without it is not recommended due to the imminent wear of the drive belt.

To replace a regular old engine with an imported one, you must follow the step-by-step instructions.

A competent algorithm of work is organized as follows.

- First, unscrew the hardware of the native engine, move aside the gas and muffler wiring.

- Remove the motor from the chassis.

- Attach the new engine and mark the areas on the frame where you will need to drill holes.

- Put on the new engine, slide the drive belt over it and drag it along the chassis until the drive belt is tight. Make sure that the engine friction wheel and gear wheel are in the same plane.

- Fasten the engine to the chassis with bolts.

- Connect the power train channels.

Before operation, the restored unit must be properly “run in” at idle speed.

How to set up and repair the "Mole" motor-cultivator, you will learn from the following video.

The comment was sent successfully.