All About Garden Concrete Curbs

Garden concrete curbs surround paths, flower beds, flower beds. From the material in this article, you will learn about their pros and cons, varieties. In addition, we will tell you how to make them yourself.

Advantages and disadvantages

Concrete curbs are functional and aesthetic garden fences. They differ from the road curb in their lower height and beveled front side. The width of such products is 8 cm, the length can be 0.5 or 1 m. The advantage of the curb is a wide range of applications. Concrete curbs are mounted in residential areas, in car parks, used in cottage and suburban construction. With their help, they emphasize the accents of the landscape, including flower beds, free-standing trees (used for the tree trunk circle).

Curbstone has many advantages:

- performs the functions of delimiting the zones of the site;

- strengthens the boundaries of road surfaces;

- differs in the variability of design and shape;

- characterized by durability and availability;

- frost-resistant, inert to temperature extremes;

- suitable for landscape gardening and urban decoration;

- differs in color and type of constituent elements;

- environmentally friendly, easy to clean;

- durable, decorative, practical;

- resistant to mechanical stress;

- provides for the replacement of elements if necessary.

The key disadvantage of concrete curbs is weight, which makes it difficult to mount and dismantle the edging.

Due to its heavy weight, it is difficult to move or move it if you want to change the size and shape of the fenced area. Therefore, before installation, you need to plan the type of structure and its exact location.

Varieties

Concrete curbstone comes in many forms. The curb can be classified according to different criteria. For example, concrete curbs are separate and monolithic.

By location method

The entire assortment of concrete garden curbs is divided into 2 groups: 1-sided and 2-sided. Each type is different.

- Modifications of the first group are used in tiered sites. A one-sided curb is needed where 1 side of the fenced area is above (below) the other. Its shape is rectangular, slightly beveled at the top on one side.

- Bilateral analogs perform a dividing function. They are narrow, rounded at the top, and have an extended base. They are used to visually separate the surface of the same height (sidewalk, lawn).

By appointment

Concrete curb varies in scope and is divided into 3 types. Each of them has its own characteristics.

Its weight, brand and manufacturing method depend on the purpose of the fence. These data are spelled out in GOST 6665-91.

Garden

Garden curbstone is used in landscaping. It is made from fine-grained concrete, it is framed by flower beds and paths, choosing the desired shades of the edge. In comparison with other analogs, it weighs less and is not so bulky. It is an excellent protective barrier for paths from dirt from the surface of the lawn. Approximate weight is 40 kg, in terms of compressive strength - class B22.

Sidewalk

The decorative sidewalk curb is slightly larger than the garden counterpart. In general, it is not that difficult to install.It can be used to decorate the sidewalks of the adjoining territories of country houses. Sidewalk curb - prevention of destruction of paths, it ennobles the developed area, outlines the boundaries of movement on a clean surface.

Road

This curb is larger than the previous counterparts, its height is higher. Its strength characteristics are better. Such a fence is installed along sidewalks and highways, preserving their integrity. It is made from a mixture of heavy concrete. It is able to protect people from accidental collision with a car.

Shape and dimensions

Sizes are directly related to the purpose and shape, which, in addition to the standard one, can be very diverse. The landscape can be decorated not only with a thin, but also shaped stone, for example, a radius (semicircular) or monolithic round. Round fences are most often used to delineate flower beds.

According to GOST 6665 * 91, side stones have several forms:

- BR - ordinary rectilinear;

- BU - straight line with broadening;

- BUP - straight-line with discontinuous expansion;

- BL - straight with a tray;

- BK - curved;

- BV - incoming airborne.

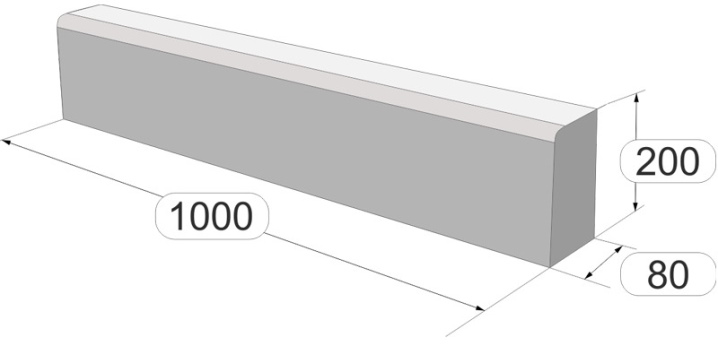

The dimensions of an ordinary garden concrete border according to GOST are 1000x200x80 mm. In this case, the parameters of the decorative chamfer on the upper edge are 15x15x45 degrees. Concrete curb for flower beds can have other dimensions (for example, 500x210x70, 500x200x80, 1000x300 ... 340x180 mm).

By order of the buyer, it is possible to manufacture blocks with a length of 500, 600, 800 mm. In this case, you can agree with the manufacturer on the preferred type of form. In addition to the usual look, today you can even order curly blocks or columns. At the same time, lawn stone can have a different color and style.

Tools and materials

Self-production of a garden curb stone from concrete will take a lot of time, this is the main drawback of decorating the landscape of the local area in the country with your own hands. The site can be landscaped in 2 ways: by installing piece elements and by pouring a monolithic structure of the preferred shape and size.

To make a garden curb yourself, you will need special forms for pouring the solution. They are metal and polymer, sold in specialized stores, and are used many times. Forms are not only available for purchase, but also for rent. They can be made from scrap materials, for example, from:

- flower containers;

- reflectors from unnecessary fluorescent bulbs;

- scraps of pipes with thin walls.

If necessary, you can make forms from metal sheets, plywood, planed boards and other materials. For the solution you need to prepare:

- cement M 400 or M 500;

- sand;

- fine crushed stone (gravel no more than 4 cm);

- plasticizer for concrete;

- cold water;

- pigment for concrete (if required).

You will also need a construction mixer or concrete mixer, a vibrating table, a building level, a tape measure, a container for mixing a solution. It is worth preparing a spatula, shovel and trowel in advance. Casting type of stone will require the installation of formwork. To create it, it is necessary to prepare sheet material with a smooth surface type (plywood, boards, metal sheets).

If it seems difficult to do it yourself, you can buy a ready-made formwork made at the factory. Its elements are fixed by means of nails, pins, bars.

To strengthen the structure, use reinforcement with a diameter of rods of 0.6 cm. Casting stone allows you to create borders of different shapes: with curves, turns, decorative elements. The choice of the type of fence depends on the complexity of the shape of the enclosed object. Also in the work you will need a hacksaw, cord, hammer.

DIY manufacturing steps

The creation of a curbstone consists of two successive steps: preparation of a solution and its pouring into molds, followed by demolding.

Solution preparation

Depending on the type of cement used, the mixing ratio may vary. Usually cement, sand and gravel are taken in a ratio of 1x2.5x3 for cement grade M 400 and 1x3x4 for grade M 500. Immediately, 1⁄2 part of the norm of sand and crushed stone is laid in a concrete mixer. Then they are mixed for 2-3 minutes. The consumption of raw materials depends on the number of stones and their size.

Next, add the full rate of cement, the rest of the sand and crushed stone. Mixing is carried out for 4-5 minutes. The plasticizer is dissolved in water, after which the liquid is poured into the dry mixture. Water is added gradually, forming a concreting composition of the required viscosity.

If a colored pouring compound is needed, the pigment is added to the water before pouring into the dry mix.

When using a concrete mixer, all components are placed in the device without stopping it.

Pouring into forms

In order not to spoil the curb blocks when removing them from the molds, immediately before pouring, the surface of the molds inside is lubricated with vegetable oil or other fatty composition (for example, machine oil). They are placed on a vibrating table to obtain better quality concrete blocks. If there is no vibrating table, a hammer is used to compact the mixture. They are tapped on the sides of the molds so that air comes out of the concrete.

If you cannot do without reinforcement, the forms are filled with concrete by half. Reinforcing rods are cut, after which they are placed in molds and poured to the top. Compaction is then performed. The solution is left in molds for 2 days, after which they are demolded. After that, the blocks must be kept for at least 4 weeks. All this time, the stone is moistened with water. Spraying is the prevention of cracks in finished blocks.

They can then be used to mount the fence. If the holding regime is not followed, the stones may crack during operation.

If desired, various decorative components can be added to the solution: broken glass, pebbles, mosaics. So that they are located along the top edge of the border, they are placed on the bottom of the molds before pouring.

If a drawing is planned by design, it is stamped with a stamp until the concrete is completely frozen. When it is necessary to decorate the border with an LED garland, a longitudinal recess is made in the side of the blocks.

Installing the curb

Concrete blocks are installed on the edge or on the wide side. According to the installation rules, the blocks are mounted before the start of paving using the following technology:

- along the boundaries of the future track (platform, flower beds), a trench is dug to the depth of laying;

- prepare concrete;

- fences are installed on fresh concrete at a level (they should be buried by about 1⁄2);

- after the concrete has dried, fill in a trench from the facade of the paving.

Piece stones are installed with a gap of 3-4 mm at the end. They are poured with concrete, rammed with a bayonet. The gaps are covered with a thin spatula. The stone should not protrude above the ground level by more than 5 cm.

Correctly installing a monolithic concrete curb is not difficult. Its installation is carried out on a pillow, deepening into the soil. When digging trenches, a depth of 1/3 of the height of the stone is taken into account. Also, the height of the pillow (10-15 cm) is added to the parameters.

When constructing new paths, stones are installed immediately. Prepared ditches are tamped, sand or crushed stone is poured, then it is compacted. Next, they are engaged in the installation of formwork from the edges of the trench. After preparation, the formwork is poured with concrete mass. The mixture is compacted, then the top is leveled with a spatula. After three days, the shields are removed. The advantage of a cast stone is the absence of seams.

During the installation, an important nuance must be taken into account: the installation of borders for flower beds and bulk paths is different.

The flower bed located on the lawn is fenced with a stone on a sand cushion. The stability of the blocks will be ensured by their weight. Metal pins are installed in piece blocks.

The load on the curbs along the paths is greater. In this case, prevention of block creep and deformation is necessary. Their installation is carried out on a cement mortar. The technology involves pouring sand and gravel onto the bottom of the trench. After that, the solution is poured and the blocks are installed. They are leveled at the level or stretched lace. When the solution grasps, they begin to backfill the trench with soil and compact it.

How to paint?

If you want to change the color of gray concrete borders, you can refine them. water-based facade paint... Such materials are used for painting facades and other surfaces on the street.

You can decorate the surface of concrete with a breathable and waterproof compound (for example, based on acrylic).

There is a special paint for concrete stone in the assortment of building stores. You can paint the surface of the fence with a polyurethane-based paint. Such coloring products are resistant to fading and abrasion. You can refine the surface of the curb special paint for paving slabs, road paint, enduring any temperature extremes.

You can learn how to properly install a concrete garden curb on your site from the video below.

The comment was sent successfully.