What is birch suvel and how is it harvested?

Birch suvel is an unusual natural formation, which is popularly called birch bone. Those craftsmen who specialize in woodworking know the value of this unusual growth. Working with suvel, you can make beautiful products with pleasant and high-quality natural characteristics.

What it is?

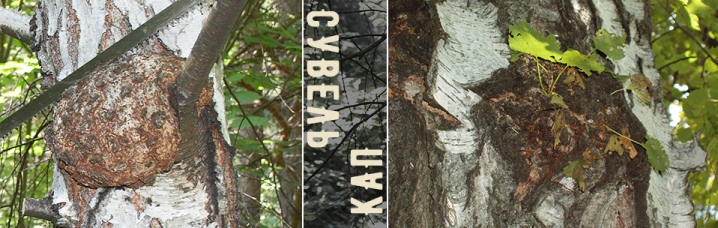

Suvel is an outgrowth resource for a person, but for the birch itself it does not mean anything good. This growth appears due to a tree disease (figuratively speaking, due to birch cancer). Usually it is a lump, twisted and woven, without a clear geometric shape. Another popular name for the build-up is swil. And this swile grows 2, or even 3 times faster than the tree itself.

In shape, it resembles either a drop, or a ball, or something averaged. The growth is located around a branch or trunk. On birch, such formations are often found, although it is impossible to say exactly what caused them and why they develop. It is believed that the suvel appears due to the attack of the tree by the fungus. But mechanical injury to birch cannot be ruled out.

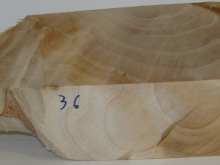

But this outgrowth is called a tree bone because the cut of the suvel resembles streaks of marble, with a cross-section and rays characteristic of the material, and you can even see through the thin particles of the suvel. Some resemblance to the structure of bone tissue, indeed, is guessed. True, the tissue density of the build-up is still less - this wood is not as strong as, for example, burl.

It happens that the suvel grows to an enormous size. If you come to the Vatican, you can see there a baptismal font, which is made from a single piece of suvel cut from a tree. True, the gigantic size is not equal to the quality of the material. Usually, the smaller the birch bone, the brighter and richer the inner pattern. But in any case, the internal pattern of the growth is soft, without tweezers and needles.

Inside, the suvel resembles mother-of-pearl - in a shade, of course. It can be different, it can be whiter, darker, richer or more faded. Sometimes the suvel is like amber inside, it is more brown, pinkish or even greenish. The shade of the build-up inside depends on where the birch grows, as well as on the subsequent drying of this part of the tree.

By the way, the suvel can be provoked. Some people simply wire a birch trunk or a specific branch of a tree. At the site of the constriction, a bulge is formed, which is created by annual rings. But if respect for nature is a priority, you should not do this.

Suvel is also an advantageous natural formation because it behaves well during processing. The build-up lends itself well to grinding, perfectly polished. Finally, the main value of education is the same mother-of-pearl cut that resembles marble. It plays with stains in the sun, charms with its texture and even gives birth to some kind of inner light. It is impossible to say for sure, looking at the growth on a birch, what it is inside, but certain predictions can be made.

The more clumsy and twisted the build-up, the richer and more interesting its internal pattern.

How is it different from a mouthguard?

First, it's worth saying what a cap is. He also has an alternative popular name - "witch's broom". This formation, in contrast to the suvel, is of a benign nature. Nodules grow on a birch trunk or twig.This is not some kind of ball or large drop, but a nodular formation, with many bumps that create dormant kidneys (or adventitious). These formations resemble either thorns or tubercles. It is not surprising if small shoots and small twigs will grow on the burl, right from its gut. With a swirl, this is out of the question.

The differences between these entities are significant.

For example, a burl is a rare and successful find. It is believed that it can be found on one of 3-5 thousand trees. Suvel is easier to find. On birches, people often find a root burl, and it can also be of impressive size. It is not as easy to process a burl as a suvel, but bumps, bumps and thorns make themselves felt. But there should be no problems with grinding and polishing.

The wood of the suvel is not as strong as that of the burl. It is at least twice as strong as that of the birch on which the burl grew. Cigarette cases and boxes, earrings, bracelets, hairpins, and small decor are often made of burl. But a carved pattern on the cap is never created (well, maybe only desperate experimenters), because it will be superfluous.

The texture and texture of this rare wood element does not need excessive decoration.

Features of the workpiece

You need to look for an unusual bulge, of course, in the forest. Both burl and swil, by the way, are very often confused with woody mushroom. Its name is even difficult to remember - the Inonotus is beveled. But to put it simply, this is what people call chaga.

Such a mushroom grows on a birch, and it is possible to meet it on a tree more often than a suvel, and even more so a burl.

Here are some tips for finding and harvesting a swirl.

-

Cutting the swile is optimal in the fall (as well as the burl, however). If they are already very gnarled, autumn harvesting is especially appropriate.

-

Cutting the build-up is not easy - you may have to use a chainsaw for this. True, here, too, a problem may arise - the saw chains quickly become blunt under the influence of a stubborn, very durable build-up.

-

In the absence of a chainsaw, a hand tool is also suitable, but only one with sharply sharpened teeth. If the saw is dull, it will be hard for both the master and the tree, who are dangerously injured by such manipulations.

-

So that an unnecessary hollow does not accidentally form on the tree, the places where the suvel is cut should be covered with garden varnish as soon as possible. Instead of var, clay and putty with oil paint will do.

-

If a swel of huge sizes is found, it is worth seriously considering whether to cut down the formation. If you take away such an outgrowth from a tree, you can inflict severe damage on it: the wound will be so serious that the tree risks dying.

-

Initial processing is variable. You can leave the wood outdoors in the most natural conditions, but it will take a year or even two to dry naturally. You can speed up the process as follows: the bark is removed from the workpiece, wrapped in newspaper, placed in a black polyethylene bag. The paper will prevent the material from rushing to heat, and the bag will create a greenhouse effect. If the suvel is dried outside, the black polyethylene will quickly heat up from the sun, if at home - from the battery. The process is uniform, which means you don't have to worry about cracking the tree. The bag is tied, leaving a small vent. Everything will take about 25 days.

But collecting, drying is just the beginning of the process. Next, the souvel must be cooked.

Processing secrets

The cooking method described below is quite popular. Moreover, it is suitable both to give the wood the desired shade, and to force drying, and to make the natural pattern more expressive.

Suveli is cooked according to a certain scheme.

-

Only workpieces cleaned of bark are placed in the pan. They are poured with water so that the liquid covers the material by 3 cm. Then add 2 tablespoons of salt to 1 liter of water, put the container on fire. Sawdust is added to the solution: alder or birch are suitable, the needles will also work. They are needed as a natural dye.

-

Once the water has boiled, the heat is reduced and the boil lasts 4 hours. If you have to process a very large workpiece - all 6 hours.Then the water is drained, the wood is left to dry. On the second and third day, the processes are repeated. In total, cooking should take at least 12 hours (up to 18) for three days in a row.

Why it is necessary to cook in a saline solution - simple physics works. There is sap in the tree, and its density is lower than that of the saline solution. During cooking, water enters the material, dehydration begins. The tree sap is displaced and the saline solution is absorbed. This is how the elementary diffusion of the liquid occurs, and the build-up is dried.

After cooking, the material must be wrapped in newspaper and sent in a bag. The next day, the swill is still wet and can dry out without any extra measures. In extreme cases, you can dry the material for one more day in the newspaper.

The processing of the build-up is rough and final. When roughing, a saw cut is made in the material such as is pleasing to the future shape of the product. If it is, for example, a bowl, the inner part is selected from top to bottom. Excess wood is removed by moving from the walls to the center, observing an angle of 45 degrees. A drill or chisel will help with this. It is not especially necessary to thin the walls: when dry, they may turn out to be too fragile, even cracking is not excluded. When the product is in its original shape, it is left outdoors for a couple of days, not in direct sunlight.

Finishing is the removal of the angularity of the forms, the maximum advancement to the final appearance of the product, the disclosure of the structure of the birch bone.

If in the course of this work material flaws, small cracks are revealed, a mixture of glue and sawdust will help out. After that, you can clean the roughness: with a rasp or a scraper, the wire brush also works. It is necessary to act often and small, carefully. You can grind the product with a drill, or better by hand - with a sandpaper.

It remains only to clean the finished product from dust, to protonate, if such is the intention. Wood growth is sometimes treated with varnish, sometimes with wax, and hot drying oil is also used. And this process is long, labor costs are significant. But after all, there are a lot of products made from suvel.

Application

Crafts made from birch bone are varied - what the author's imagination will not create. Jewelry is considered the most popular: original jewelry, which today, in the era of eco-style, boho design trends is especially in demand. Such jewelry will suit those who love natural materials, natural colors - beige, milky, green, sand.

They make very beautiful dishes from birch bone. The most popular name today is probably cutting boards. But the handles of the knives, of course, compete with the boards - and this is already a tradition. The material is dense, easy to work with, very beautiful, therefore knife handles will certainly be in demand. Knives serve for years, even decades. Repair in the kitchen can change, a large part of the dishes too, so knives need solid and beautiful, timeless and changeable fashion. And the birch bone handles fit perfectly.

Figures of birds and animals also allow you to make a suvel, because the woody pattern so visually repeats the plumage of birds, the skin of a snake or the fur of animals. The bends of the material themselves inspire the author, tell the master what exactly to do. Wood drawing may not be an independent craft, but part of the decoration of a painting, panel, or other art object.

In a word, someone who loves to tinker with wood, knows the value of wood decor, will have 100 and 1 idea about a birch growth called suvel. And you can be sure that the birch bone product will serve for many years.

The comment was sent successfully.