How to adjust the carburetor of the brushcutters?

A petrol cutter or trimmer, despite its relative simplicity (compared to a car engine), sooner or later fails. There comes a time when long downtime and restarts of the gasoline unit cannot be avoided - maintenance is needed. In advanced cases, repair is required, or rather, replacement of worn-out parts with the same new ones. Until you are faced with the need to replace your worn-out parts, carburetor maintenance is required - cleaning, rinsing, reconfiguring mechanisms.

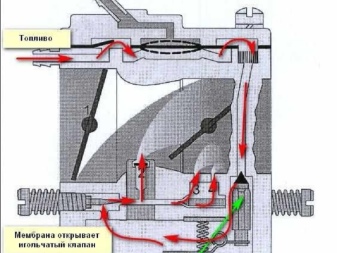

Carburetor device

The benzokos (brushcutter) contains a base - a body made of aluminum, in which the rest of the parts are placed, working harmoniously as a whole. The carburetor body has a diffuser - a stroke with internal channels through which air is pumped.

The larger the cross-section of the diffuser, the more actively oxygen is supplied together with air - an oxidizing agent, in which the fuel is burned (gasoline-oil mixture).

Channels branching off from the diffuser stroke deliver fuel, with which the forced air mixes, carrying gasoline vapors with it. Outside the main carburetor compartment are located:

- jets;

- mini fuel pump;

- unit regulating the mixing of fuel with air.

The latter forms the very explosive mixture ignited in the carburetor combustion chamber.

Principle of operation

Fuel injection and filtration procedure in the engine, the petrol cutters are next.

- The throttle valve controls the amount of air supplied to the diffuser. The more air is supplied, the more oxygen the gasoline needs to burn, and the more power is generated in the form of heat. Heat energy is further converted into mechanical energy.

- The diaphragm pump delivers the required amount of gasoline.

- Further, the gasoline passes through the engine choke.

- The fuel flows through the intake and exhaust valves.

- The fuel is filtered using a mesh filter.

- Through the needle valve, it also enters the chamber with the membrane.

The staging of the carburetor is as follows.

- Air enters the duct with an air damper. The damper sets the required air flow rate.

- In the gasoline injection unit, the diffuser is narrowed - this is necessary to give a higher air flow rate.

- The fuel passes through the compartment with the float and passes the nozzle, enters this narrowing of the tube. The float chamber doses the gasoline supply. In this compartment, the pressure is in equilibrium. In a narrowed tube, it goes down. Due to the difference in both pressure values, gasoline and passes through the jet.

- The accelerated flow sprays gasoline, converting it into aerosol vapors. The resulting gasoline-air mixture is ready for ignition in the combustion chamber.

- Having passed through the fuel line, this mixture is in the carburetor cylinder.

Conclusion: in order to set the required power, first of all, you will adjust the rate of fuel combustion using the air damper. If the gap is too small, and oxygen in such a mixture is less than 10%, the fuel does not burn, therefore, the engine will not start or will immediately stall.

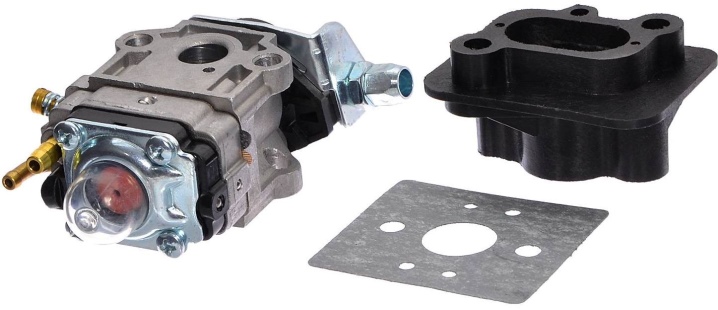

In the case of buying a Chinese trimmer, it is worth considering that it differs little from European ones - the same 2- or 4-stroke engine and drive.

However, they save on the quality of parts, forcing the consumer to change them more often.Check what compatible parts non-Chinese companies offer for your device.

Major problems

Malfunctions of the carburetor of a brushcutter or trimmer, despite the relative ease of their elimination, sometimes require a long search by the method of elimination. The main reasons are:

- unsatisfactory quality of gasoline purification;

- air filter clogging;

- accumulation of deposits and carbon deposits in the compartments and strokes of the carburetor.

Each of the problems has its own reasons.

Defective fuel pump

The most repetitive breakdown is wear and tear of the diaphragm. As a result, its non-conformity. The fuel passages are not sealed at certain stages in the engine cycle. The reasons are as follows:

- you have been working on the brushcutter or trimmer for too long without interruption;

- fueled with low-quality fuel;

- exhaust gases enter the impulse channel.

A deformed membrane is fraught with several bad consequences:

- there is not enough gasoline or oxygen in the generated combustible mixture;

- the motor starts after 10 or more unsuccessful attempts;

- the engine knocks, clinks during operation, etc.;

- the working piston is deformed.

As a result, the inner space of the fuel pump is contaminated from the side of the impulse channel.

Strainer clogged

The reasons for the clogging of the mesh filter are poor-quality fuel cleaning, damage to the hose and / or delivery head.

Failure of the adjusting lever

The wear of the contact edge of the lever is a consequence of an incompletely purified fuel, into which grains of sand or particles of clay, metal or other inclusions that are not soluble in liquid hydrocarbons have gotten. There is a problem with fuel injection, the engine does not function properly without load.

The inlet needle is broken

The inlet needle breaks due to metal and stone particles in the gasoline. As a result, the seat of the inlet needle does not fit snugly against it, the fuel mixture flows. There is too much air in the combustible mixture created by the carburetor, which can cause the engine to "sneeze" during operation. Finally, the needle may become stuck due to low-quality gasoline, or the unit has been idle for a long time.

Blocking the adjusting space

Deposits can build up in the control compartment. The needle does not completely close the hole, and a lot of gasoline enters the fuel chamber - the engine overflows it, possibly fills the spark plugs as well. Because of this, the gasoline-air mixture contains an increased amount of gasoline vapors. The efficiency drops noticeably.

The regulation membrane is damaged

The membrane often deforms (sometimes breaks) due to the continuous operation of the brushcutter or trimmer for several hours. If you abuse this "shock" mode of operation, membrane damage occurs more often. New breakdowns will sprinkle like a cornucopia:

- the piston will break;

- the number of unsuccessful engine start attempts will increase dramatically;

- the fuel mixture contains too little gasoline;

- the useful (thermal) power will drop sharply.

Intake control lever is sticking

Jamming of the adjusting lever is a consequence of its incorrect installation, accidental bending. The contacting face will get the wrong position. This will disrupt the additional gasoline injection.

Damper worn out

The throttle valve and air damper become unusable due to the entry of dust, metal particles, etc., with the air flow. Damaged dampers look like sandblasted parts. Due to wear on the dampers, the efficiency of the motor decreases, and breakdowns are detected. The piston and cylinder are worn out.

The dampers become unusable due to improper maintenance of the air filter or its breakdown.

In some cases, this filter is simply not suitable for your brushcutter or trimmer model. In the end, the motor shaft will suffer - its pieces fall into the engine channels, causing the piston to be broken.

Carburetor cannot be adjusted

The fact that the adjustment is too coarse (it is not possible to accurately set the parameters) are to blame for the springs on the adjusting screws. A brushcutter or trimmer manufacturer may supply unnecessarily thick and stiff springs. Others can be found either in workshops where similar equipment is repaired, or purchased from any dealer or official representative of the company that produced the motor for your trimmer or power scythe.

Broken primer

Primer - a hand-held mini-pump for forced pumping of fuel into the carburetor. To start the engine successfully, it may be necessary to manually pump 20 ml of gasoline.

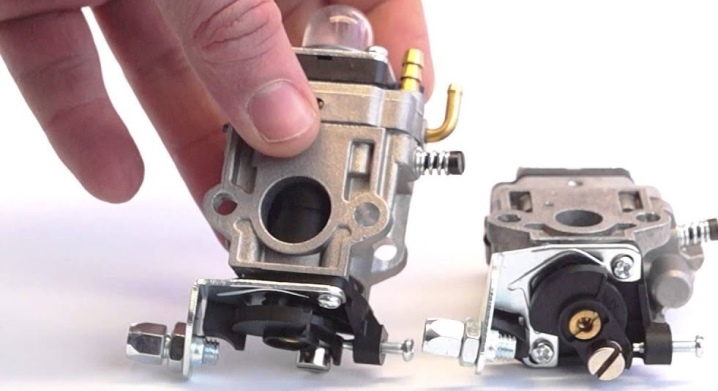

Elimination methods

List of upcoming work with the engine could be as follows:

- replacement of the fuel pump;

- disassembly and flushing of the strainer;

- replacement of the adjusting lever;

- it is also necessary to clean the adjustment space;

- replacement of the membrane (or the entire block where this membrane is located);

- adjusting the inlet, outlet and needle valves;

- replacement of dampers;

- cleaning fuel channels and diffuser;

- replacement of screw springs;

- change of primer.

Not all of this work can be done. It often turns out that many of them are not needed if a specific malfunction is immediately detected.

Adjusting the carburetor on a petrol cutter

Diagnosing and adjusting the carburetor with your own hands can take just a few minutes.

Rinse the filters before starting it (see instructions). You can adjust the carburetor yourself using three adjusting screws.

Start the engine to get it right. Your actions are as follows.

- Find the idle speed limit. To do this, unscrew screw L to the right and then to the left. The turning step is a quarter of a turn counterclockwise.

- With the screw T you can adjust the idle speed of the motor: increase when turning the screw clockwise, decrease - vice versa. The adjusted engine works confidently without load and without warming up. Warmed up - does not overestimate the speed.

- If you are not adjusting the brushcutter, but the trimmer, then the turns of the T screw set a greater reserve in terms of rpm. For both types of devices, stable revolutions are set when the cutting height is selected with the knife (or line).

- The last screw is turned H. It sets the rate of supply of gasoline with air at close to maximum speed, engine power, engine warm-up temperature and fuel consumption.

To tune the motor using screw H, do the following.

- Open the throttle and squeeze the throttle at full throttle.

- Turn screw H clockwise until the engine speed decreases.

- Turn the same screw slowly counterclockwise until the engine produces an irregular rpm.

- Turn the propeller back slightly (clockwise) until the motor runs smoothly. It is important to grasp this line.

Fine tuning results in complete combustion and a brownish white spark plug. A gasoline-filled candle is much darker than a non-refillable candle.

How to adjust the carburetor of the brushcutters, see below.

The comment was sent successfully.