Error codes for malfunctions of Zanussi washing machines and how to fix them

Every owner of a Zanussi washing machine can face a situation when the equipment fails. In order not to panic, you need to know what this or that error code means and learn how to fix them.

Diagnostic modes for washing machines with different control panels

The Zanussi washing machine is considered reliable unit, but, like any technique, it needs prevention and proper care. If you neglect these procedures, you may be faced with the fact that the device will give an error and refuse to work. You can check the performance of the elements yourself using the instructions below. The options may vary depending on the model of your device. A horizontal or top-loading vending machine may vary by scenario.

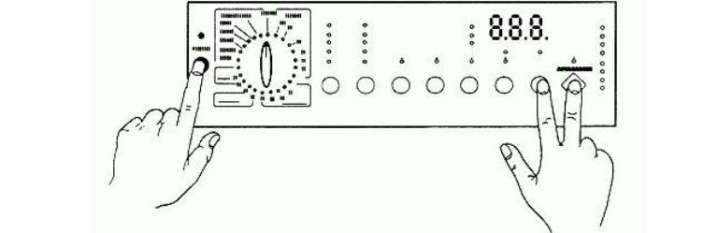

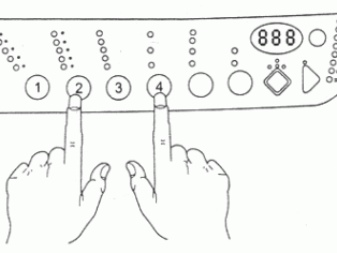

All manipulations are performed in test mode. The diagnostic mode is entered by setting the selector to the "off" mode. and then pressing the start button and the buttons shown in the figure.

When the indicator light starts blinking, it means that the machine is in test mode.

EWM 1000

This line has 7 ways to check for faults. Between switching, you will need to maintain a five-minute pause for the diagnosis to be successful. Before proceeding, remove all clothing from the tank. The EWM 1000 is diagnosed as follows.

- The program selector is in the first position. Here you can check the functionality of the buttons. When pressed, they should be highlighted or emit a sound alert.

- When you turn the selector to the second position, you can check the water filling valve in the dispenser with the base wash. At this stage, the door lock will be triggered. The pressure switch is responsible for the liquid level.

- The third mode controls the prewash liquid fill valve. When you select it, the door lock will also work, the set sensor is responsible for the water level.

- Fourth position will turn on two valves.

- Fifth mode not used for this type of machine.

- Sixth position - this is a check of the heating element along with the temperature sensor. If the liquid level does not reach the desired mark, the CM will pick up the required amount additionally.

- Seventh mode tests the operation of the motor. In this mode, the engine scrolls in both directions with further acceleration to 250 rpm.

- Eighth position - This is the control of the water pump and spinning. At this stage, the maximum engine speed is observed.

To exit test mode, you need to turn the device on and off twice.

EWM 2000

Diagnostics of this line of washing machines is as follows.

- First position - diagnostics of the water supply for the main wash.

- Second position is responsible for supplying water to the prewash compartment.

- Third provision controls the water supply to the air-conditioned compartment.

- Fourth mode responsible for supplying liquid to the bleach compartment. Not every device has this feature.

- Fifth position - This is the diagnosis of heating with circulation. Also not present in every model.

- Sixth mode needed in order to test the tightness.During it, water is poured into the drum, and the engine rotates at high speeds.

- Seventh position checks drain, spin, level sensors.

- Eighth mode needed for models with a drying mode.

Each of the steps tests the door lock and fluid level, along with the function of the pressure switch.

Error codes and possible causes of their occurrence

To understand the types of breakdowns of Zanussi brand “washing machines”, you need to familiarize yourself with the notation of their common mistakes.

- E02. Engine circuit error. Usually reports about the inoperability of the triac.

- E10, E11. During such an error, the machine does not collect water, or the bay will be accompanied by too slow a set. In most cases, the breakdown lies in the clogging of the filter, which is located on the intake valve. You should also check the pressure level in the plumbing system. Sometimes the malfunction is hidden in the damage to the valve, which lets water into the tank of the washing machine.

- E20, E21. The unit does not drain water after the end of the wash cycle. Attention should be paid to the condition of the drain pump and filters (clogging may form in the latter), to the performance of the ECU.

- EF1. Indicates that there is a blockage in the drain filter, hoses or nozzles, therefore, water is drained from the tank at a slow speed.

- EF4. There is no signal that should go to the indicator responsible for the passage of liquid through the open filler valve. Troubleshooting begins by checking the pressure in the plumbing system and examining the inlet strainer.

- EA3. There is no fixation from the engine pulley rotation processor. Usually the breakdown is a damaged drive belt.

- E31. Pressure sensor error. This code indicates that the frequency of the indicator is outside the permissible value or there is an open circuit in the electrical circuit. Replacement of pressure switch or wiring is required.

- E50. Engine error. It is recommended to check electric brushes, wiring, connectors.

- E52. If such a code appears, this indicates the absence of a signal from the tachograph of the drive belt.

- E61... The heating element does not heat the liquid. It stops heating up for a certain period. Typically, scale forms on it, due to which the element fails.

- E69. The heating element does not work. Check the circuit for an open circuit and the heater itself.

- E40. The door is not closed. You will need to check the status of the lock.

- E41. Leaking door closing.

- E42. The sunroof lock is out of order.

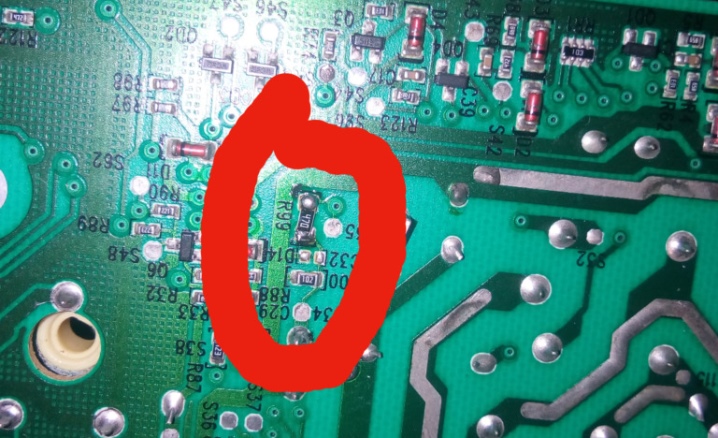

- E43... Damage to the triac on the computer board. This element is responsible for the UBL functionality.

- E44. Door close sensor error.

Most often, users are faced with the fact that they cannot open the door after washing, the hatch does not close, or water is not collected. Also, the machine can emit a high level of noise, whistle, there are cases when it does not wring out or leaks. Some problems home craftsmen can fix on their own.

The door does not open

Typically, a similar phenomenon occurs when the lock is defective. The bottom panel must be removed to open the unit. Next to the filter, on the right side, there is a special cable that can be pulled and the hatch will open.

These actions should be done in a situation when the washing is completed and you need to remove the washed laundry.

In the future, all the same, the machine must be returned for repair, since such an error indicates a malfunction of the electronic component of the device. There is also a situation when the user cannot close the door. This suggests that the hatch latches themselves are faulty. You will need to disassemble the lock and replace damaged parts.

Water is not collected

There may be several reasons, so several steps will be required.

- First of all, you should check if there is water in the water supply... To do this, you need to disconnect the filling hose from the tank and turn on the water. If fluid comes in, the hose is put back on.

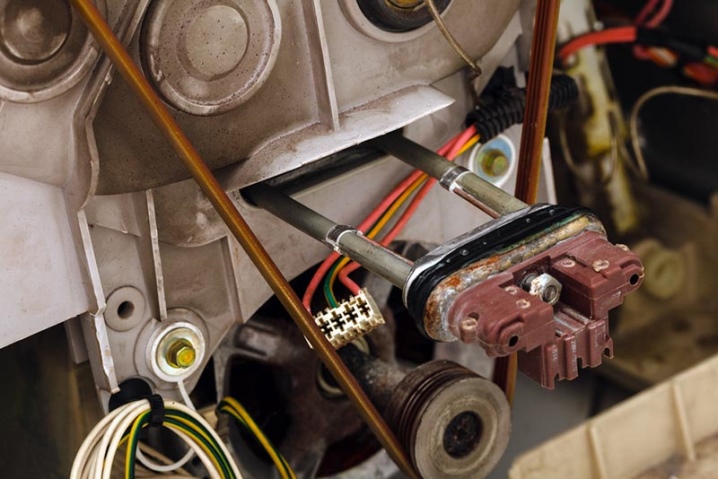

- Then you will need to remove the top cover and disconnect the filter from the priming valve. If the filtration system is clogged, it must be cleaned. Filter maintenance is a regular procedure that should not be neglected.

- Next, you need to examine the mesh for blockage. It is located next to the valve. If necessary, rinse it out.

- To check the functionality of the valve, it is necessary to apply a voltage to its contacts, the rating of which is indicated on the body. If the mechanism has opened, then everything is in order with it. If the part does not open, you need to replace it.

- If all the actions taken did not help to solve the problem, you should seek help from a specialist.

Loud spin noise

An increased noise level may indicate that there is little laundry in the tub or a broken bearing. If the cause is in the bearing, it must be replaced. This requires the following procedure.

- It is necessary to pull out the tank, remove the drum pulley.

- Then the fastening bolts located along the edges are unscrewed.

- The drum shaft is removed from the bearing. This is done by lightly tapping with a hammer on the wood substrate.

- The bearing mount is cleaned, along with the axle shaft itself.

- Then a new part is put in, the half-axle ring is lubricated.

- The last stage is the assembly of the tank, lubrication of the joints with a sealant.

The machine does not spin the drum

If the drum is stuck, but the engine continues to run smoothly, consider bearing or drive belt problems. In the first option, the bearing or its oil seal should be replaced. In the second situation, you should dismantle the rear case and check the belt. If it slips or breaks, it must be replaced. For a displaced one, only an adjustment to the desired position is required. If the electric motor does not turn on, and the drum can only be rotated by your own efforts, several details should be checked:

- Control block;

- electric brushes;

- voltage level for drops.

Repair anyway it is recommended to trust only a professional master.

Recognition by indicator signals

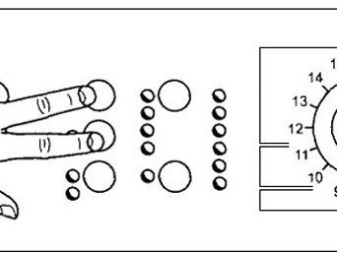

On models not equipped with a display, the codes are checked using indicators. The number of indicators may vary and depends on the model of the washing machine. To figure out how to recognize an error by indicators, you can on the example of the Zanussi aquacycle 1006 with the EWM 1000 module. The error will be indicated by the light indication of the "start / pause" and "end of the program" lamps. The blinking of the indicators is carried out quickly with a pause of a couple of seconds. Since everything happens quickly, users may find it difficult to define.

The number of flashes of the “end of program” lamp indicates the first digit of the error. The number of "start" flashes shows the second digit. For example, if there are 4 flashes of "program completion" and 3 "starts", this indicates that there is an error E43. You can also consider example of code recognition on a Zanussi aquacycle 1000 typewriter, with the EWM2000 module. The determination takes place using 8 indicators, which are located on the control panel.

In the Zanussi aquacycle 1000 model, all indicators are located on the right (in other versions, the location of the bulbs may differ). The first 4 indicators report the first digit of the error, and the lower part reports the second.

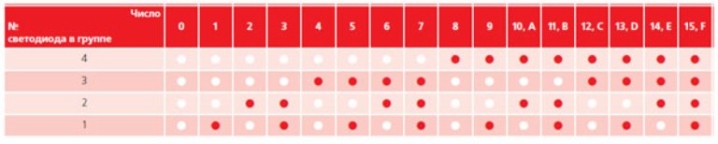

The number of light signals lit up at a time indicates a binary error code.

Decryption will require the use of a plate. The numbering is carried out from bottom to top.

How do I reset the error?

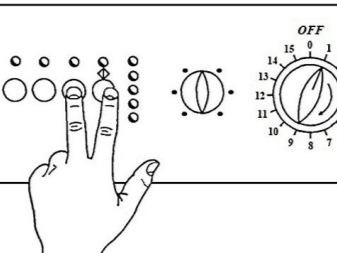

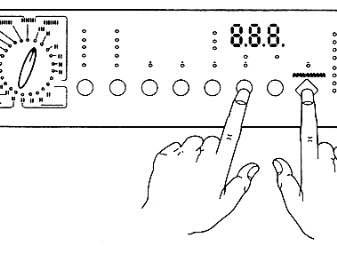

To reset errors on the unit with EWM 1000 module, you will need to set the mode selector to the tenth position and hold down a couple of keys, as shown in the figure.

If all the indicator lights flash, then the error has been cleared.

For devices with an EWM 2000 module, proceed as follows.

- The selector is turned in the direction opposite to the movement of the clockwise by two values from the "off" mode.

- The display will show the fault code... If there is no display, the indicator light will come on.

- To reset, you need to press the "start" button and the sixth button. The manipulation is performed in test mode.

Errors of Zanussi washing machines are shown in the video.

The comment was sent successfully.