What to do if the machine knocks out when you turn on the washing machine?

At times, users happen to be faced with the fact that when starting the washing machine, the automatic machine or during the washing process knocks out the plugs. Of course, the unit itself (with an incomplete wash cycle) and all the electricity in the house is immediately turned off. Such a problem should not be left unresolved.

Description of the problem

As mentioned above, it happens that large household appliances, especially a washing machine, knock out an RCD (residual current device), plugs or an automatic machine. The equipment does not have time to complete the wash, the program stops, and at the same time the light disappears in the entire home. Sometimes it happens that there is light, but the machine still does not connect. As a rule, it is possible to detect a malfunction and eliminate the cause on our own. The main thing is to have an idea of what to examine and how.

Moreover, with the right approach, it is possible to detect the cause of the shutdown even without specialized metering devices.

The reason should be sought in the following:

- wiring problems;

- malfunction in the unit itself.

Inspection of wiring

An RCD can operate due to a number of factors.

- Incorrect configuration and device selection. The residual current device may have a small capacity or be completely defective. Then the shutdown will occur during various operations of the washing machine. To eliminate the problem, it is necessary to perform the adjustment or replace the machine.

- Congestion of the power grid... It is advisable not to operate several powerful electrical appliances at once. For example, when starting a washing machine, wait with a microwave oven or a powerful electric stove. The power of the machine is 2-5 kW.

- Failure of the electrical wiring itself or the outlet... In order to find out, it is enough to connect household appliances with such power to the network. If the RCD trips again, then the problem is definitely in the wiring.

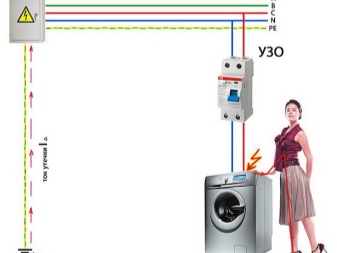

Checking the correct connection of equipment

The washing machine comes into contact with electricity and liquid at the same time, and therefore is a potentially unsafe device. A competent connection protects the person and the equipment itself.

Wires

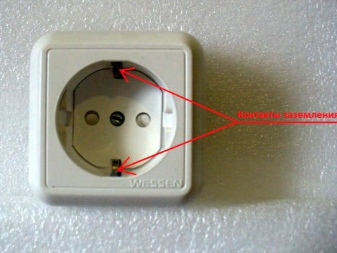

The machine must be plugged into a grounded outlet to avoid electrical shock. It is recommended to use an individual wiring line coming directly from the power distribution board. This is necessary in order to relieve other electrical wiring from overload, since a powerful thermoelectric heater (TEN) operates in the washing unit during washing.

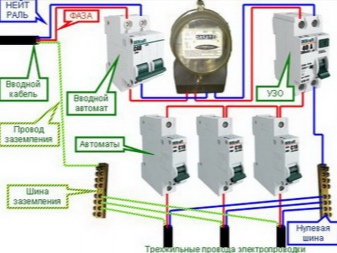

The wiring must have 3 copper conductors with a cross section of at least 2.5 sq. mm, with a free-standing circuit breaker and a residual current device.

RCD

Washing machines have various powers up to 2.2 kW and more, their connection must be made through an RCD in order to ensure the safety of people from electric shock. The device must be selected taking into account the power consumption. The component is designed for 16, 25 or 32 A, the leakage current is 10-30 mA.

Machine

In addition, the connection of equipment can be realized through a difavtomat (circuit breaker with differential protection). Its selection takes place in the same order as an RCD. The marking of the appliance for the household power supply must be with the letter C... The corresponding class is marked with the letter A. There are machines of the AC class, only they are less suitable for operation with solid loads.

Causes of malfunctions in the washing machine itself

When the electrical wiring has been inspected and the identified malfunctions are eliminated, however, the RCD is triggered again, therefore, malfunctions have arisen in the machine. Before inspection or diagnostics, the unit must be de-energized, make sure that there is no water in the machine. Otherwise, there is a high risk of electrical and possibly mechanical injuries, since there are rotating units and assemblies in the machine.

There are a number of factors why it knocks out plugs, a counter or an RCD:

- due to a breakdown of the plug, power cable;

- due to the closure of the thermoelectric heater;

- due to failure of the filter to suppress interference from the supply network (mains filter);

- due to a broken electric motor;

- due to failure of the control button;

- due to damaged and frayed wires.

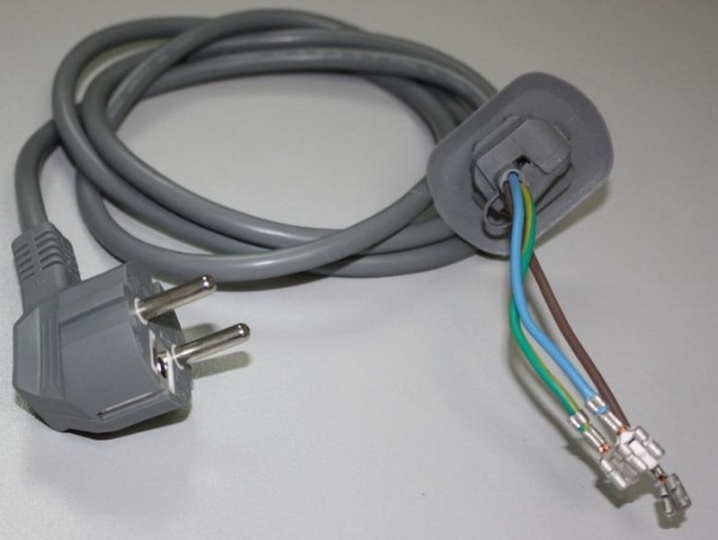

Damage to the plug, power cable

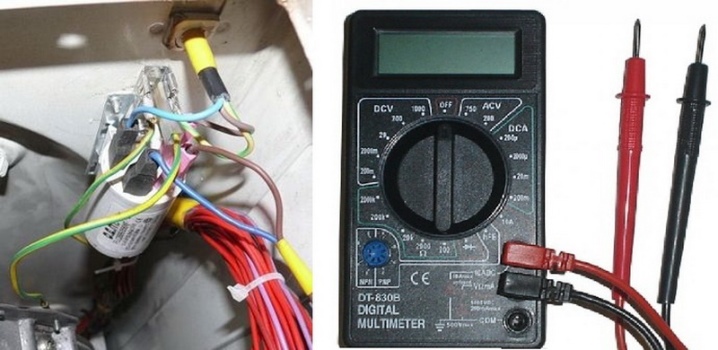

Diagnosis invariably starts with an electrical wire and plug. During use, the cable is subjected to mechanical stress: it is crushed, overlapped, stretched. The plug and the electrical outlet are poorly connected due to a malfunction. The cable is tested for faults with an ampere-volt-wattmeter.

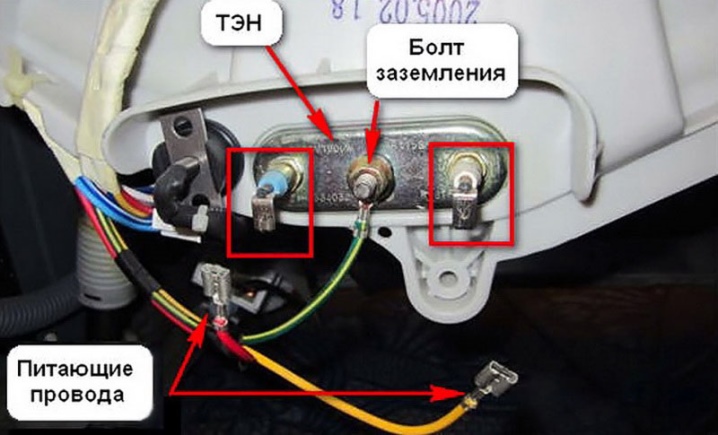

Short circuit of the thermoelectric heater (TENA)

Due to the poor quality of water and household chemicals, the thermoelectric heater is "eaten away", various foreign substances and scale are deposited, the transfer of thermal energy becomes worse, the thermoelectric heater overheats - this is how a bridging occurs. As a result, he knocks out the electric meter and traffic jams. To diagnose the heating element, the electric power cable is disconnected and the resistance is measured with an ampere-volt-wattmeter, setting the maximum value at the “200” Ohm mark. In a normal state, the resistance should range from 20 to 50 ohms.

Sometimes the thermoelectric heater closes to the body. To weed out such a factor, take turns measuring the leads and the grounding screws for resistance. Even a small indicator of the ampere-volt-wattmeter reports a short circuit, and this is a factor in the shutdown of the residual current device.

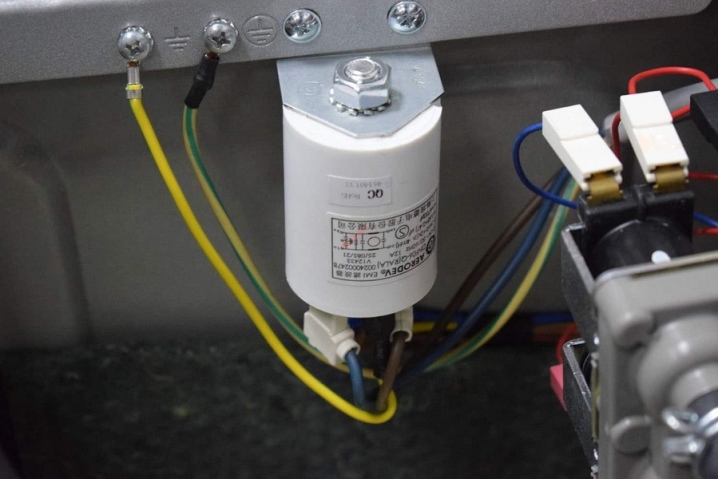

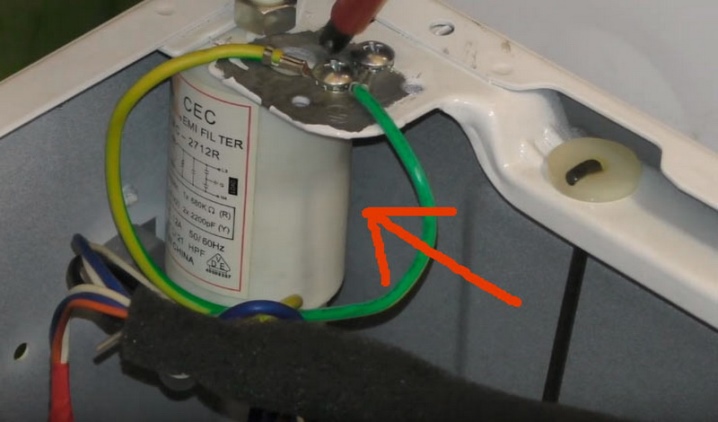

Failure of the filter to suppress interference from the mains

A filter is required in order to stabilize the electrical voltage. Network drops make the node unusable; when the washing machine is turned on, the RCD and plugs are knocked out. In such a situation, the filter needs to be replaced.

The fact that the mains filter to suppress interference from the supply mains has shorted out is indicated by the reflow elements on the contacts. The filter is tested by ringing the incoming and outgoing wiring with an ampere-volt-wattmeter. In certain brands of cars, an electrical cable is installed in the filter, which equally needs to be changed.

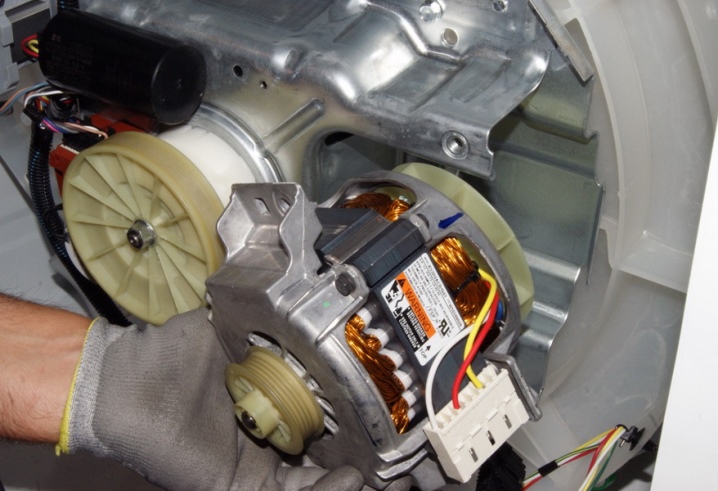

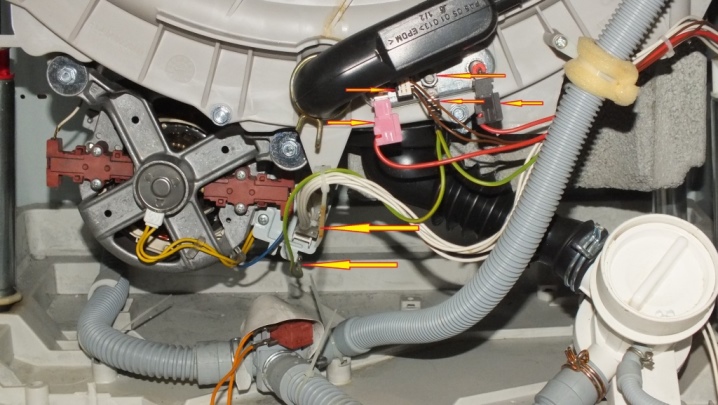

Malfunction of the electric motor

The reason for the short circuit of the electrical wiring of the electric motor is not excluded with long-term use of the unit or violation of the integrity of the hose, tank. The contacts of the electric motor and the surface of the washing machine alternately ring out. In addition, the plugs or the circuit breaker of the residual current device knocks out due to wear of the brushes of the electric motor.

Failure of control buttons and contacts

The electric button is used most often, in this regard, the inspection should begin with its check. During the initial examination, you may notice contacts that have oxidized and worn out. An amperevolt-wattmeter is used to check the wires and contacts leading to the control panel, electric motor, thermoelectric heater, pump and other units.

Damaged and frayed electrical wires

Deterioration of electrical wires is usually formed in an inaccessible place of the washing machine. When the unit vibrates in the process of draining water or spinning, the electrical wires rub against the body, after a certain period of time the insulation is frayed. An electrical short circuit on the case becomes a consequence of the fact that the machine is triggered. Areas of damage to the electric wire are determined visually: carbon deposits appear on the insulating layer, darkened reflow zones.

These areas need soldering and secondary insulation.

Troubleshooting tips

Here we will tell you what to do in each specific case.

Replacing the power cable

If for any reason the power cable has been damaged, it must be replaced. Replacing the power cable is carried out in this way:

- you need to turn off the power to the washing machine, turn off the inlet tap;

- create conditions for draining water using a hose (it is strictly forbidden to overturn the unit);

- the screws located along the contour should be unscrewed, remove the panel;

- remove the filter from the housing to suppress interference from the mains by unscrewing the screw;

- press down on the latches, remove the plastic stopper by squeezing it out;

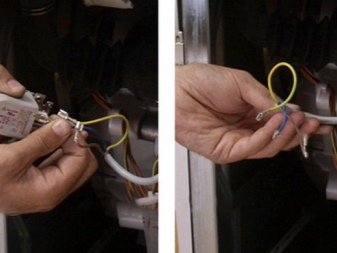

- move the electric wire inward and to the side, thus gaining access to the filter and disconnecting power from it;

- carefully remove the network cable from the machine;

To install a new cable, follow these steps in reverse order.

Replacing the heating element

Typically, the thermoelectric heater has to be replaced. How can this be done correctly?

- Dismantle the back or front panel (it all depends on the location of the heating element).

- Turn the ground screw nut a few turns.

- Carefully pick up the thermoelectric heater and remove it.

- Play all actions in reverse order, only with a new element.

Do not tighten the nut too tight. The testing machine can only be connected after it has been completely assembled.

Replacing the mains interference filter

If the filter for suppression of noise from the mains is out of order, it must be replaced. Replacing an element is simple: Disconnect the electrical wiring and unscrew the mount. A new part is mounted in the reverse order.

Electric motor repair

As mentioned above, another factor why the machine knocks out is the failure of the electric motor. It is capable of breaking for a number of reasons:

- long period of work;

- damage to the tank;

- failure of the hose;

- wear of brushes.

You can find out what exactly is out of order by ringing the contacts of the electric motor and the entire surface of the unit. If a breakdown is detected, the electric motor is replaced, if possible, the breakdown is eliminated. The place of leakage will certainly be eliminated. The brushes are dismantled by removing the contacts from the terminals. After installing the new brushes, turn the electric motor pulley by hand. If they are installed correctly, the engine will not make loud noise.

Replacing and cleaning the control button and contacts

The procedure for cleaning and replacing the control button includes the following steps.

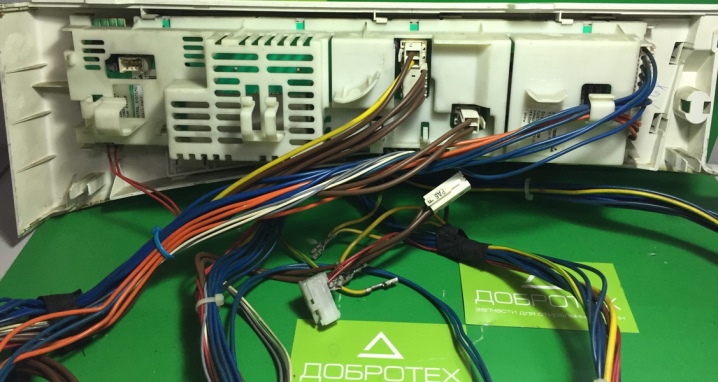

- Dismantle the top panel, which is held by 2 self-tapping screws located on the back panel. Make sure that the machine is disconnected from the power supply, the water supply valve is closed.

- Disconnect the terminals and power wires. As a rule, all terminals have different sizes of protection.... We advise you to take photographs of all the steps taken.

- Unscrew the control module and carefully pull towards the rear of the machinethus, there will be unhindered access to the buttons.

- At the final stage, cleaning or replacing buttons.

We also advise you to pay attention to the condition of the control board. Is there darkening on it, blown fuses, swollen caps of capacitors. The procedure for assembling the washing machine is carried out in the reverse order.

It must be said that knocking out the machine when starting the washing machine or washing with different modifications can for various reasons... For the most part, these are faults in the electrical wiring, however, at times one of the elements fails. Whenever possible, they should be repaired; in case of a different development of events, you will have to visit the store, select the necessary parts and replace them. It will be safer when the master does it.

Finally, I would like to warn you: when the machine kicks out when the machine is started, there is a high threat of electric shock. This is dangerous! In addition, even minor irregularities in the electrical wiring of the unit or in the electrical network lead to a fire.

What to do if the washing machine knocks out the machine when turned on, see the next video.

The comment was sent successfully.